Soot blocking pipe bundle of steam injection boiler for burning residual oil with high silt content

A steam injection boiler and ash tube technology, which is applied in the combustion method, combustion product treatment, and solid residue removal, etc., can solve problems such as the decline of boiler output and thermal efficiency, affecting the normal operation of the boiler, and the dense arrangement of convection tube bundles. The effect of reducing the concentration of fly ash, improving the recovery rate of heavy oil and increasing the convective heating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The structure of the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

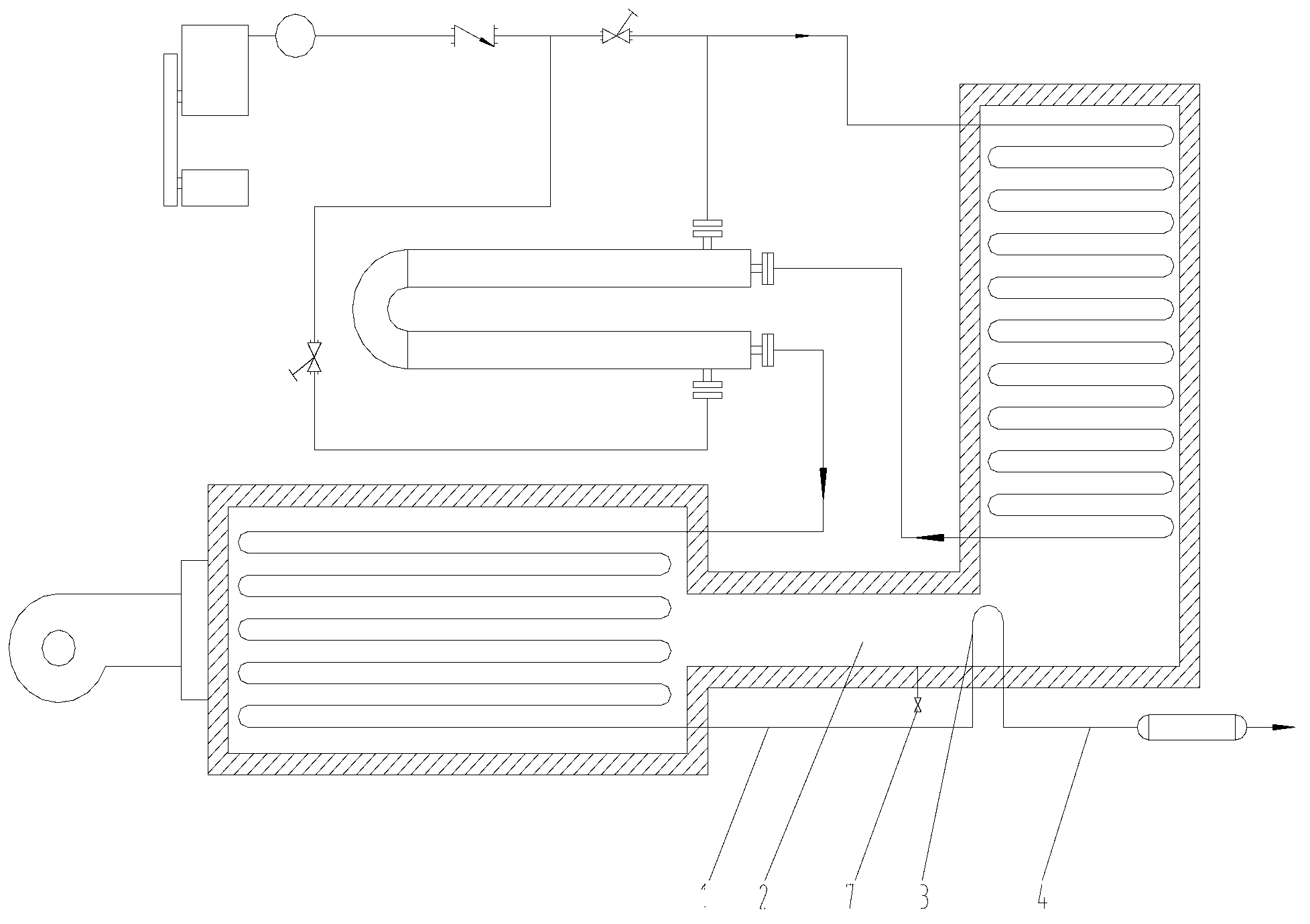

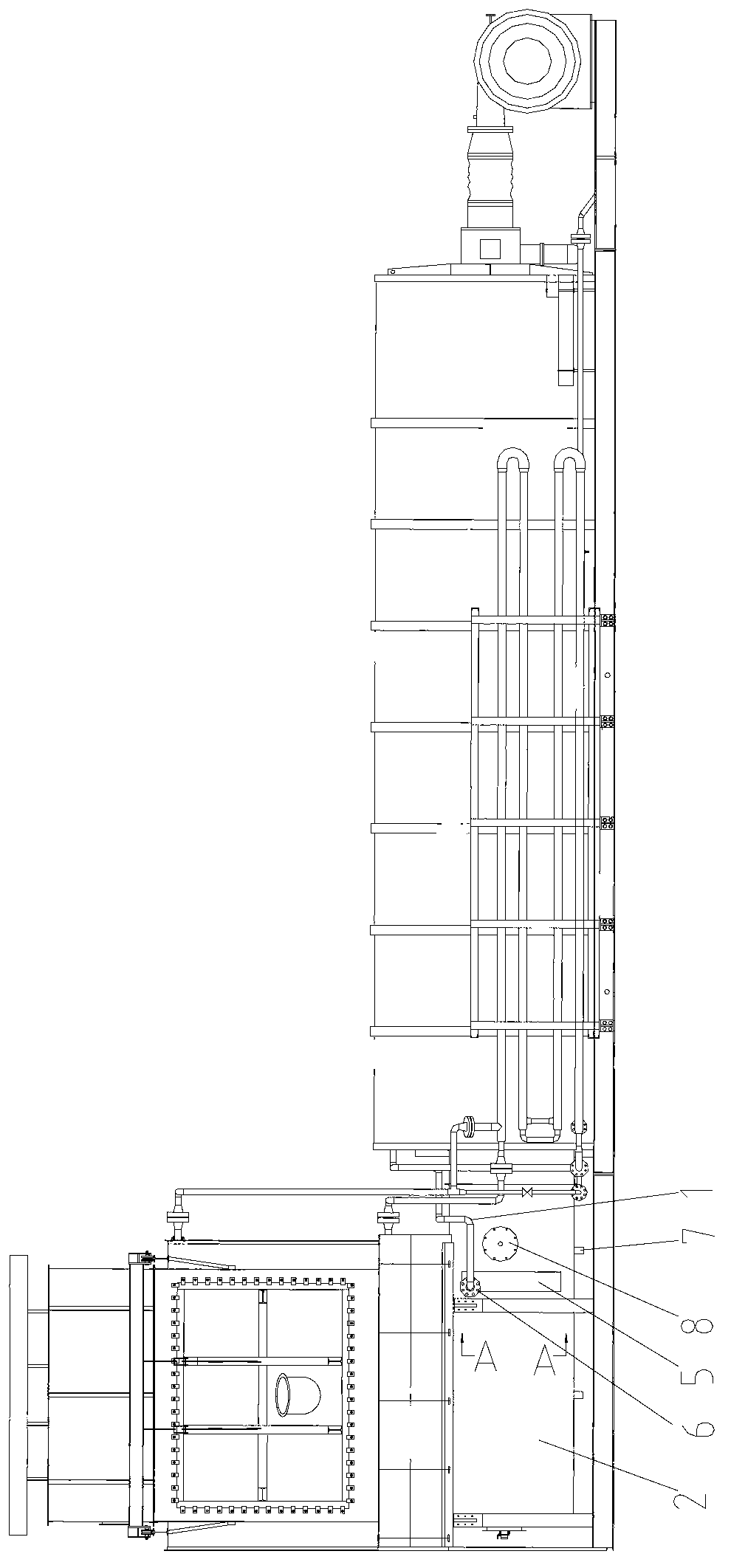

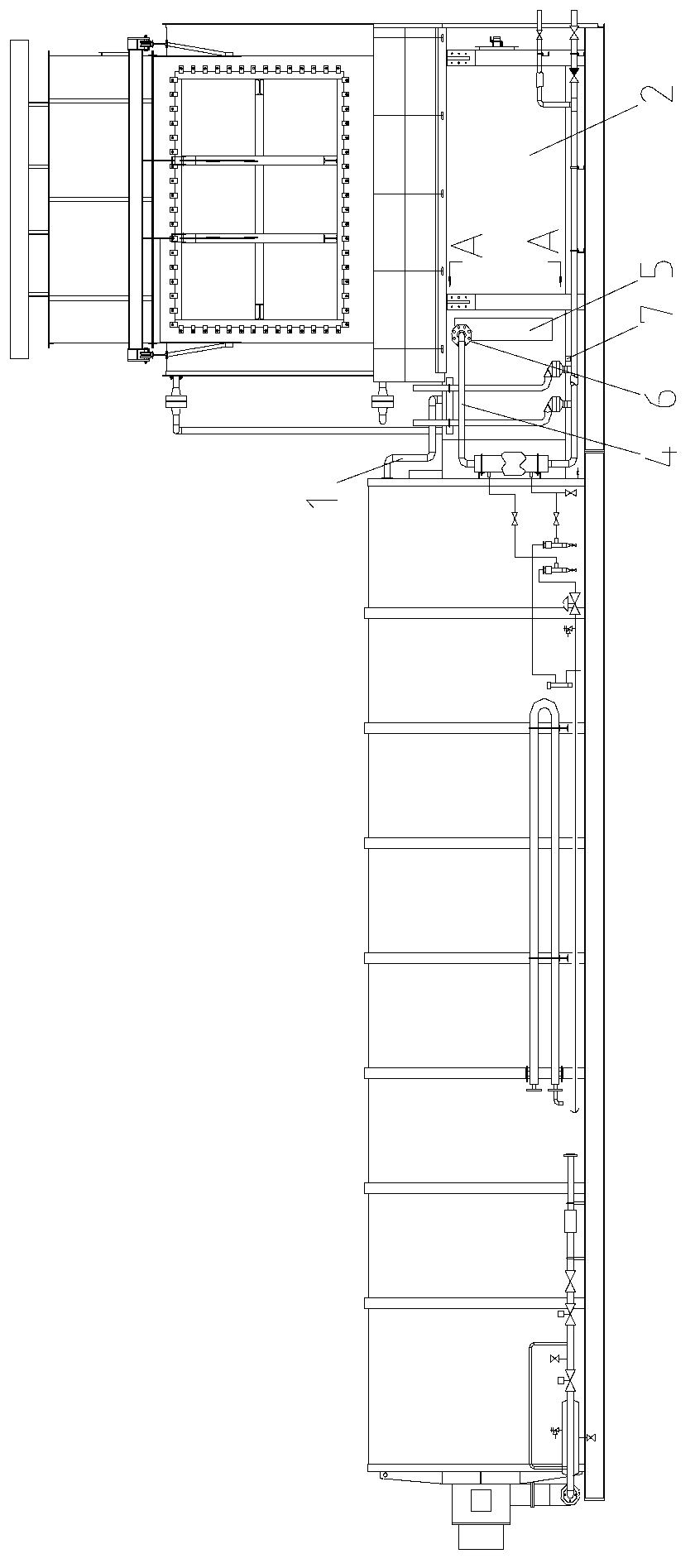

[0028] Such as figure 1 , figure 2 and image 3 As shown, the present invention is a kind of ash-retaining tube bundle used for burning residual oil steam injection boilers containing more sediment, including ash-retaining tube bundle 3, and ash-retaining tube bundle 3 is respectively connected to the inlet pipe of the ash-retaining pipe through flanges 6 at both ends. 1 is connected to the outlet pipeline 4 of the ash-retaining pipe, the inlet pipe 1 of the ash-retaining pipe is connected to the outlet of the radiation pipe, the outlet pipe 4 of the ash-retaining pipe is connected to the inlet of the steam sampling separator, and also includes a transition section 2 arranged in front of the ash-retaining pipe bundle 3 The upper soot blower 8 and the ash discharge hole 7 at the bottom of the transition section 2. The ash-retaining tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com