Electromechanical-hydraulic composite type main drive system of tunnel boring machine

A tunnel boring machine and composite technology, applied in the field of mechanical equipment, can solve the problems of lagging of auxiliary mechanical transmission devices, inability to fully utilize motor power, increase volume, etc., and achieve a large power-to-weight ratio, convenient layout, and long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

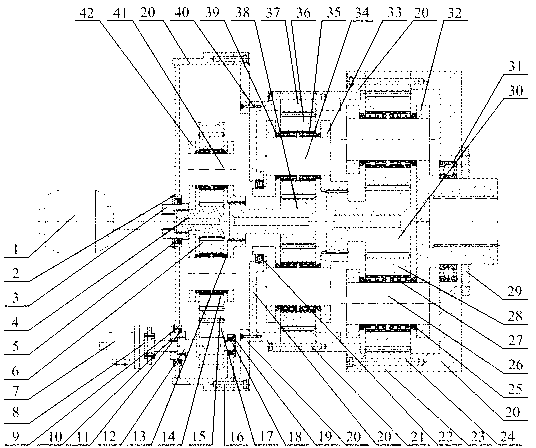

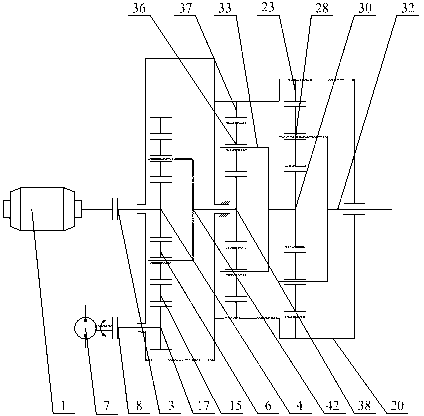

[0026] In the present invention, one hydraulic motor is selected for each reducer, the brake 8 is in the closed state, the hydraulic motor 7 brakes, the power input component motor 1 transmits power to the input stage sun gear 4, and the input stage sun gear 4 drives the input stage planet meshed with it 6, the input stage planetary gear 6 undergoes self-propagation and revolution, and transmits power to the input stage planetary carrier 42, and the input stage planetary carrier 42 is used as the input of the intermediate stage of the planetary gear pair to drive the intermediate stage sun gear 38 to rotate, and the intermediate stage sun gear The wheel shaft 38 transmits power to the intermediate planetary gear 36 and realizes power splitting. The intermediate planetary gear 36 drives the intermediate planetary carrier 33 to rotate, realizes power confluence and transmits the power to the output-stage sun gear shaft 30 through a spline connection, and the output-stage sun gear ...

Embodiment approach 2

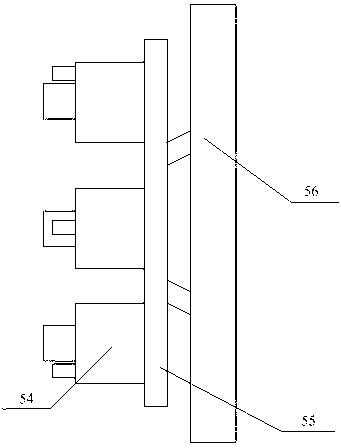

[0028] The brake 8 is in the disengaged state, the hydraulic motor 7 of the power input component drives the input external gear 17 to rotate, transmits the power to the input stage ring gear 15, and drives the input stage planet carrier 42 to rotate through the input stage planetary gear 6, and is connected with the power input component motor 1. The transmitted power confluence output, multiple reducers 54 of the main drive system of the electromechanical-hydraulic composite tunnel boring machine jointly drive the cutter head 56. At this time, the output power is large and the torque is large, which is suitable for the tunnel boring machine when the external soil and rock resistance moment is sudden. Increase or collapse the working conditions to achieve escape.

Embodiment approach 3

[0030] Such as Figure 5 As shown, the transmission and output structure of the tunnel boring machine reducer adopts the first-stage differential + NGWN planetary gear train structure, the input-stage planet carrier 42 drives the second-stage sun gear 43, the second stage adopts a planetary gear pair, and the second stage The first-stage planet carrier 45 is coaxial with the third-stage sun gear 47, and drives the third-stage planetary gear 48 to rotate, and the third-stage planetary wheel 48 rotates on a fixed axis, and finally the output shaft 44 is driven by the double gear 46 to output power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com