Process for recycling bismuth from gas sludge to prepare BiOCl (Bismuth Oxychloride)

A gas mud and process technology, applied in the field of solid waste resource utilization, can solve problems such as adverse environmental impacts, achieve the effects of saving treatment costs, realizing secondary utilization, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

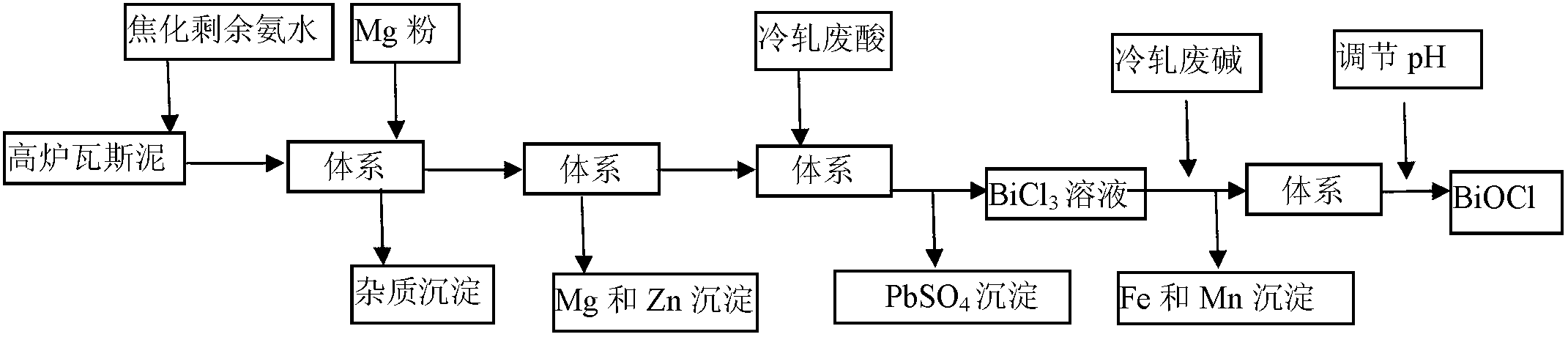

[0030] A kind of technology that reclaims bismuth to prepare BiOCl from gas mud, as figure 1 As shown, the steps are as follows:

[0031] (1) Take 1Kg of blast furnace gas mud, add 5L of residual ammonia water produced by the coking process, and soak for more than 30 minutes to dissolve the NH 3 The complexed impurity elements include Cu, Ag, Ni, Co;

[0032] (2) Add 10g of Mg powder to the above soaking system, replace the ammonium complexes of metal impurity elements that are less active than them, including Cu, Ag, Ni, and Co, into corresponding elemental forms through a replacement reaction, and remove them by filtration;

[0033] (3) Heat slowly to raise the temperature of the system to 120°C and keep it for 50 minutes, so that the magnesium and zinc elements in the system are converted into MgCO under the combined action of ammonium bicarbonate in the coking residual ammonia water 3 Precipitate or ZnCO 3 Precipitated form, removed by filtration;

[0034] (4) Add 3L o...

Embodiment 2

[0038]A kind of technology that reclaims bismuth to prepare BiOCl from gas mud, the steps are as follows:

[0039] (1) Take 1Kg of blast furnace gas mud, add 4L of residual ammonia water produced by the coking process, and soak for 1 hour to dissolve the available and NH 3 The complexed impurity elements include Cu, Ag, Ni, Co;

[0040] (2) Add 6g of Mg powder to the above soaking system, replace the ammonium complexes of metal impurity elements that are less active than them, including Cu, Ag, Ni, and Co, into corresponding elemental forms through displacement reactions, and remove them by filtration;

[0041] (3) Slowly heat to raise the temperature of the system to 100°C and keep it for 30 minutes, so that the magnesium and zinc elements in the system are converted into MgCO under the combined action of ammonium bicarbonate in the coking residual ammonia water 3 Precipitate or ZnCO 3 Precipitated form, removed by filtration;

[0042] (4) Add 2L of waste acid produced by ...

Embodiment 3

[0046] A kind of technology that reclaims bismuth to prepare BiOCl from gas mud, the steps are as follows:

[0047] (1) Take 1Kg of gas mud, add 6L of residual ammonia water produced by the coking process, and fully soak to dissolve the available and NH 3 The complexed impurity elements include Cu, Ag, Ni, Co;

[0048] (2) Add 12g of Mg powder to the above soaking system, replace the ammonium complexes of metal impurity elements that are less active than them, including Cu, Ag, Ni, and Co, into corresponding elemental forms through a replacement reaction, and remove them by filtration;

[0049] (3) Heating, raising the temperature of the system to 100°C and maintaining it for 30 minutes, so that the magnesium and zinc elements in the system are converted into MgCO under the combined action of ammonium bicarbonate in the coking residual ammonia water 3 Precipitate or ZnCO 3 Precipitated form, removed by filtration;

[0050] (4) Add 4L of waste acid produced by the cold rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com