Aged effluent oil treatment technology used for oil fields and oil refineries

A treatment process and refinery technology, applied in the direction of chemical dehydration/demulsification, mechanical dehydration/demulsification, etc., can solve the problem of low safety factor of centrifugal method, adaptability of solid content in intermittent production of waste oil, workers High labor intensity and other problems, to achieve good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

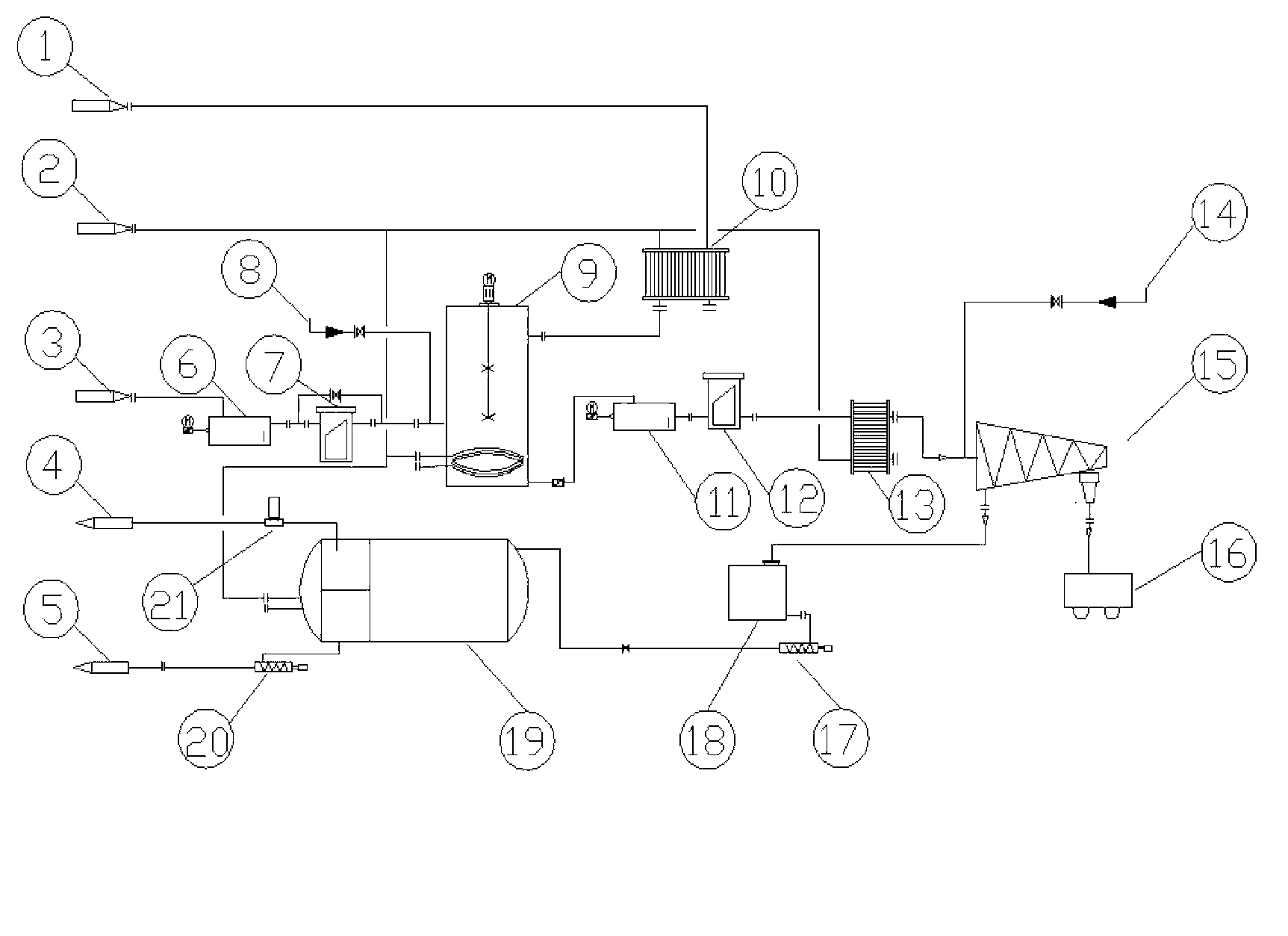

[0021] Process solution of the present invention is divided into the following steps:

[0022] First of all, this process uses a certain amount of hot water, demulsification and cleaning agents to carry out conditioning treatment on the aged dirty oil to be treated. By controlling the amount of hot water added, material temperature, and conditioning time, the aged dirty oil The impurities and precipitates that are difficult to separate are layered. This process is especially suitable for solving the problem of crude oil adhering to solid impurities in aged waste oil.

[0023] Second, this process uses a centrifugal method to separate the solid-liquid of the stratified aged dirty oil. If the first step is tank-type conditioning and the discharge port is at the bottom of the tank, the aged dirty oil with good conditioning can firstly separate the solid impurities with a density higher than water at the beginning of the centrifugation process, and then the solid impurities with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com