Preparation method for metal oleate

A technology of oleate and metal, which is applied in the field of preparation, can solve the problems of high price, low product purity, increased production cost, etc., and achieve the effect of low cost, simple process and easy equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

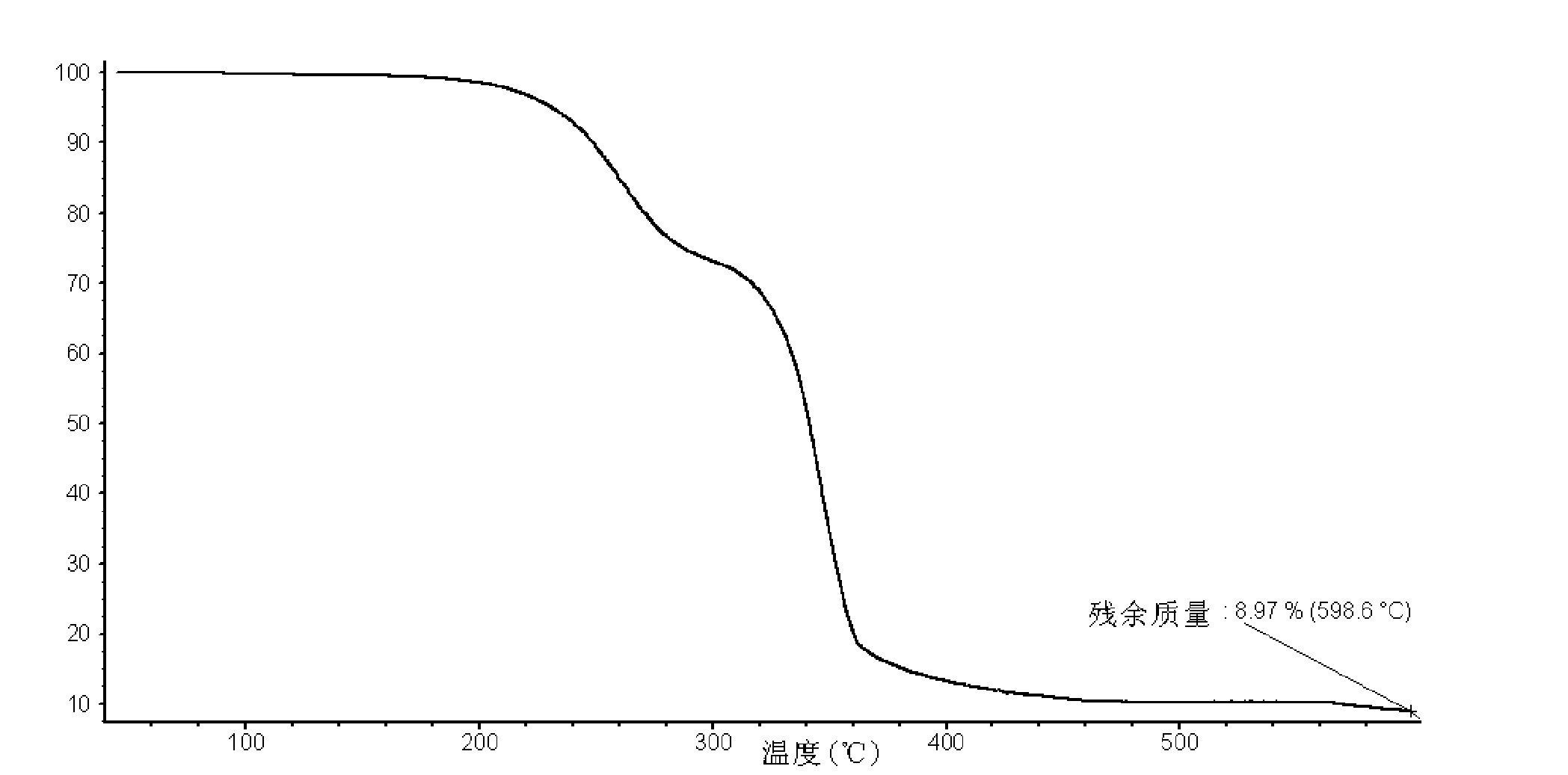

[0028] Take 20mmol of ferric chloride hexahydrate and 60mmol of sodium oleate in a 500ml one-necked flask, add 20ml of deionized water, 200ml of absolute ethanol and 60ml of n-hexane, and add a suitable magnet. Connect the single-necked flask to a spherical condenser, place it on a magnetic stirrer with a heating mantle, and use a thermocouple to control the temperature. Using condensed water to reflux, the reaction temperature was maintained at 120° C., and the reaction time continued for 5 hours. After the reaction was completed, the solution was poured into a separatory funnel and left to stand for a period of time. After the solution was completely separated, the lower transparent water phase liquid was let off to obtain a yellow oily liquid. Wash the yellow oily liquid with deionized water, let it stand again, let off the lower layer of aqueous phase liquid, and wash three times. Pour the washed yellow oily liquid into a 250ml beaker, add a magnet, heat on a magnetic sti...

Embodiment 2

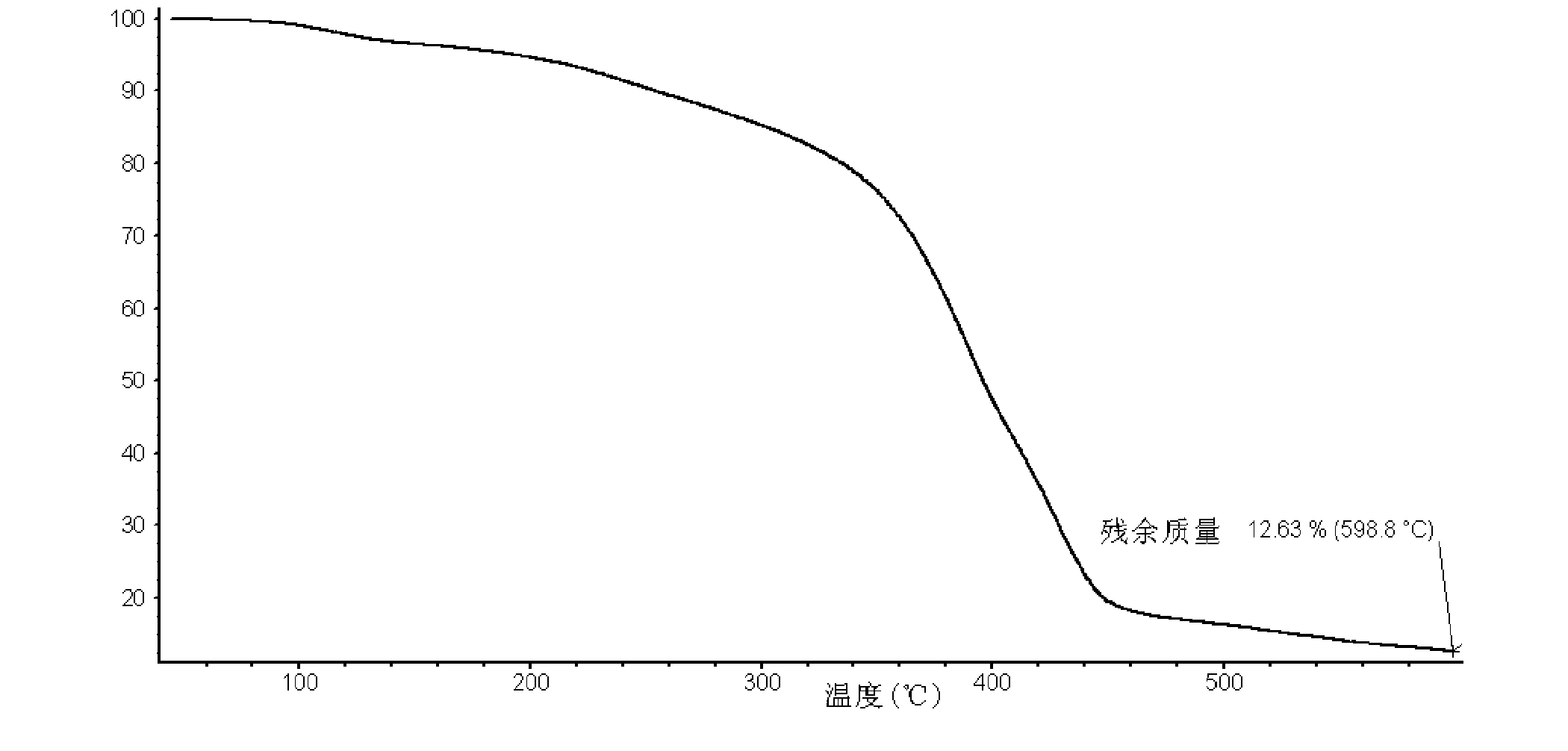

[0031] Take 40mmol of CoCl 2 and 40mmol magnesium oleate were placed in a 500ml single-necked flask, and 60ml of deionized water, 120ml of absolute ethanol and 120ml of toluene were added, and a suitable magnet was added. Connect the single-necked flask to a spherical condenser, place it on a magnetic stirrer with a heating mantle, and use a thermocouple to control the temperature. Using reflux of condensed water, the reaction temperature was maintained at 200° C., and the reaction time was continued for 0.5 hours. After the reaction is completed, the solution is poured into a separatory funnel and left to stand for a period of time. After the solution is completely layered, the lower layer of transparent water phase liquid is released to obtain an oily liquid. Wash the oily liquid with deionized water, let it stand, let off the lower layer of water phase liquid, and wash three times. Pour the washed oily liquid into a 500ml beaker, add a magnet, place it on a magnetic stirr...

Embodiment 3

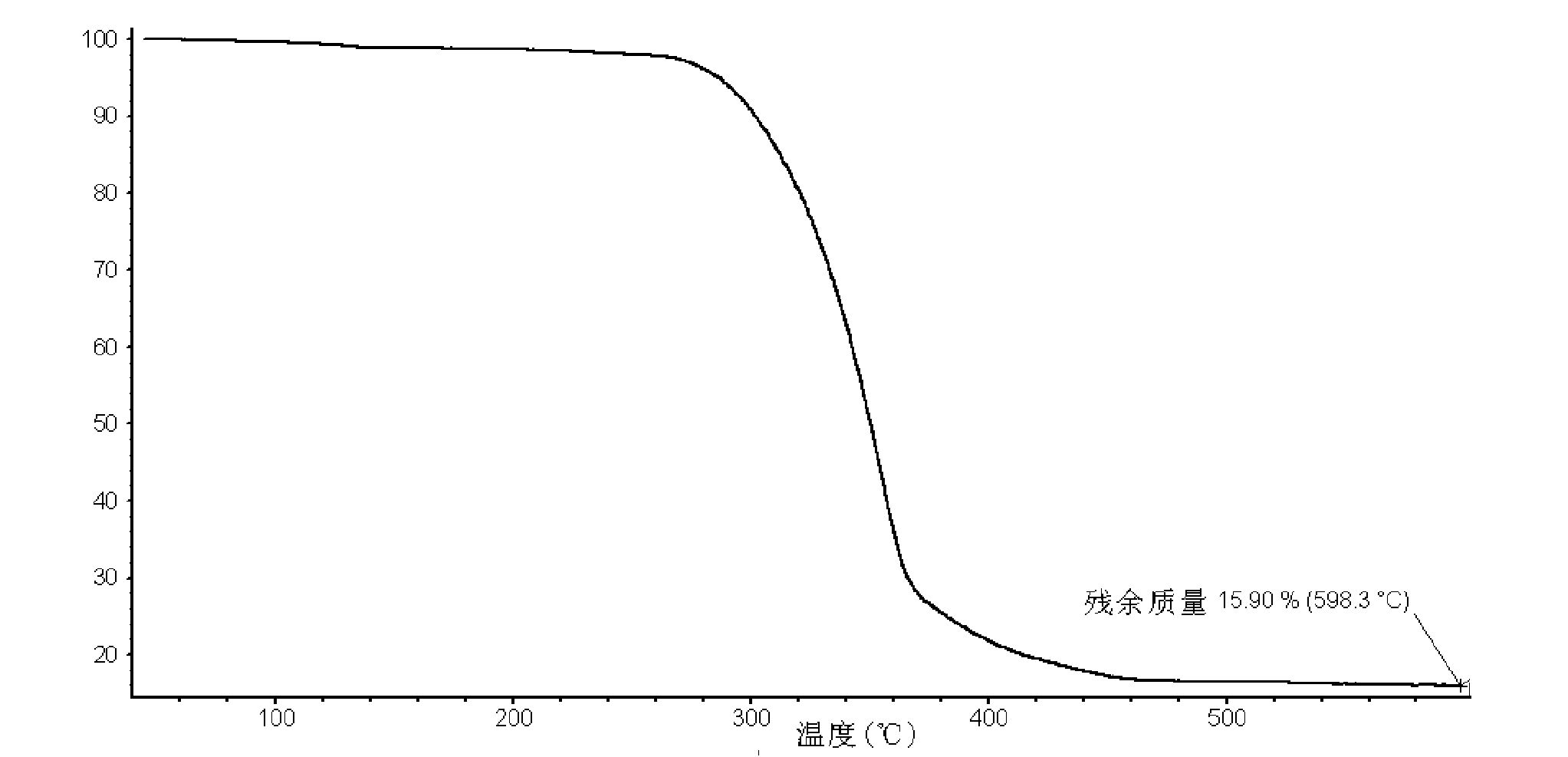

[0034] Take 10mmol of MnCl 2 and 20mmol potassium oleate were placed in a 250ml single-necked flask, and 20ml of deionized water, 80ml of absolute ethanol and 30ml of benzene were added respectively, and a suitable magnet was added. Connect the single-necked flask to a spherical condenser, place it on a magnetic stirrer with a heating mantle, and use a thermocouple to control the temperature. Using reflux of condensed water, the reaction temperature was maintained at 80° C., and the reaction time was continued for 10 hours. After the reaction is completed, the solution is poured into a separatory funnel and left to stand for a period of time. After the solution is completely layered, the lower layer of transparent water phase liquid is released to obtain an oily liquid. Wash the oily liquid with deionized water, let it stand, let off the lower layer of water phase liquid, and wash three times. Pour the washed oily liquid into a 250ml beaker, add a magnet, place it on a magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com