Preparation method of compound enhanced waterproof and fireproof heat-insulating board slurry

A composite reinforcement, fireproof and thermal insulation technology, applied in the field of external thermal insulation of building exterior walls, can solve the problems of easy detachment, pollution in the production process, and backward production technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

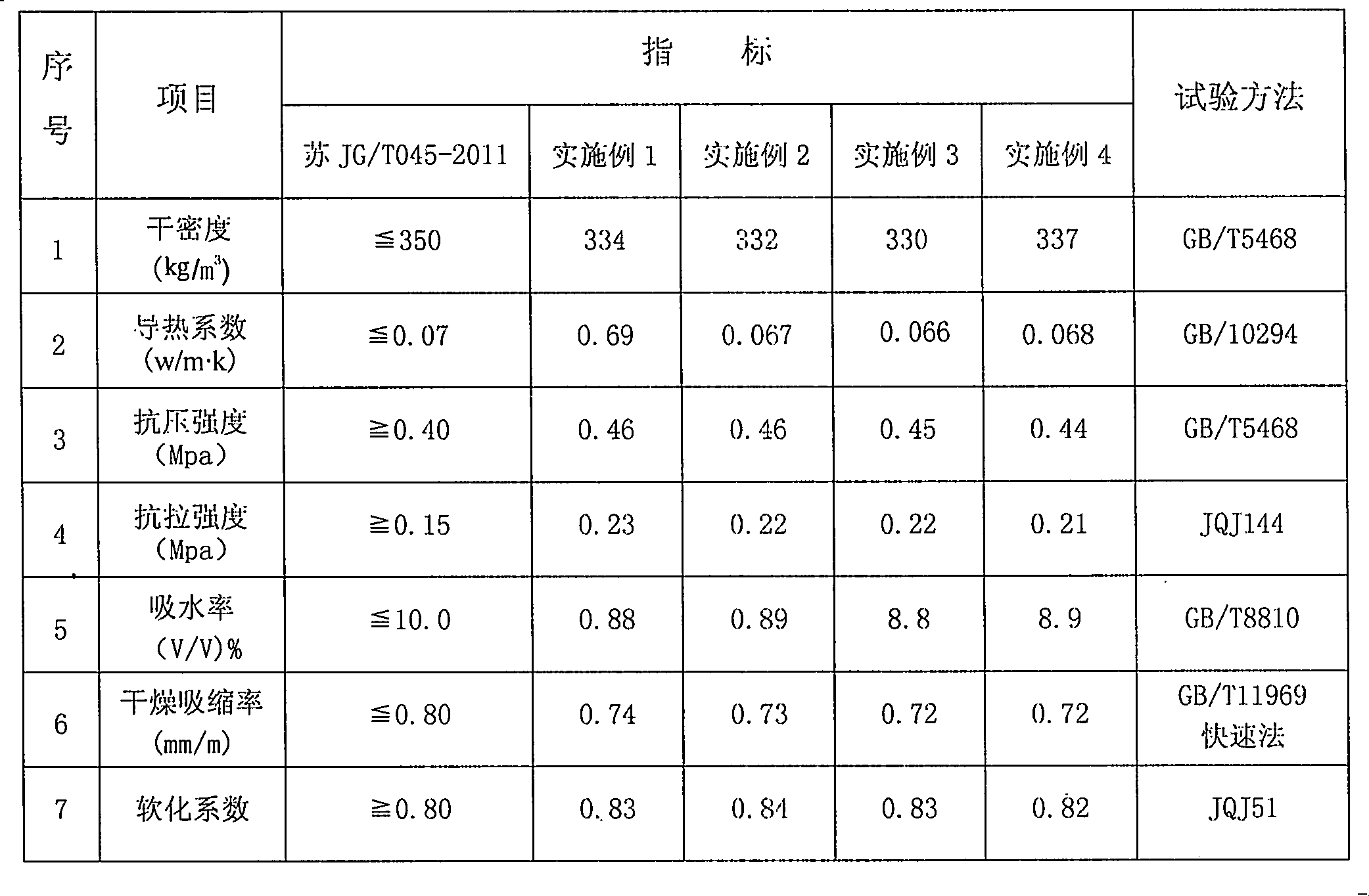

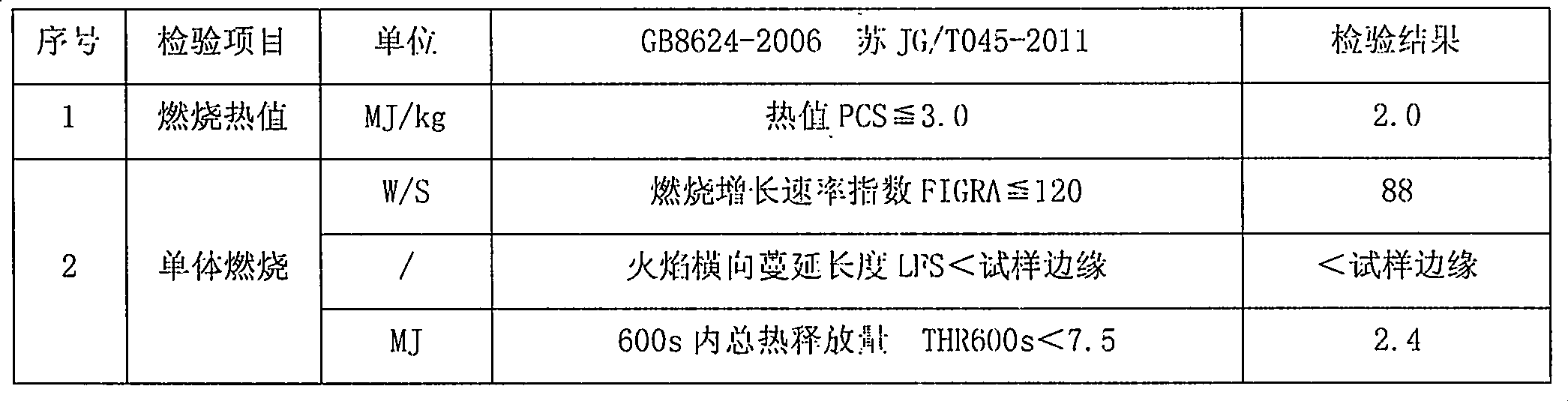

Examples

Embodiment 1

[0022] 1. Add Portland cement (42.5 type) 650kg, Class I fly ash 250kg, saltlime 65kg, redispersed latex powder 12kg, 6~8mm polypropylene fiber 1.5kg, naphthalene series to the closed logistics convection mixer. 3.5kg of high-efficiency water reducer powder, 1.5kg of methyl cellulose ether and other raw materials are subjected to three-dimensional stirring, so that the raw materials are mixed evenly and the polypropylene fibers are fully dispersed, that is, a uniformly mixed dry powder is made.

[0023] 2. Transfer 140kg of the uniformly mixed dry powder to a biaxial two-way mixer, and then add B 1 10kg of grade flame-retardant EPS particles and 100kg of water were stirred evenly to prepare the slurry for preparing the composite reinforced waterproof and fireproof insulation board.

[0024] 3. The B 1 The particle size gradation of grade flame-retardant EPS particles is: Φ2mm EPS particles account for 20% of the total weight of the EPS particles, Φ3mm EPS particles account fo...

Embodiment 2

[0026] 1. In the closed logistics convection mixer, add 700kg of Portland cement (model 42.5), 220kg of grade I fly ash, 58kg of salt lime, 14kg of redispersed latex powder, 2.0kg of 6-8mm polypropylene fiber, naphthalene series 2.8 kg of high-efficiency water reducer powder, 2.2 kg of methyl cellulose ether and other raw materials are subjected to three-dimensional stirring, so that the raw materials are mixed evenly and the polypropylene fibers are fully dispersed, that is, a uniformly mixed dry powder is produced.

[0027] 2. Transport 160kg of the uniformly mixed dry powder to a biaxial two-way mixer, and then add B 1 11kg of grade flame-retardant EPS particles and 150kg of water were stirred evenly to prepare the slurry for preparing the composite reinforced waterproof and fireproof insulation board.

[0028] 3. The B 1 The particle size gradation of grade flame-retardant EPS particles is: Φ2mm EPS particles account for 15% of the total weight of the EPS particles, Φ3mm ...

Embodiment 3

[0030] 1. In the closed logistics convection mixer, add 750kg of Portland cement (model 42.5), 190kg of grade I fly ash, 58kg of salt lime, 16kg of redispersed latex powder, 2.5kg of 6-8mm polypropylene fiber, naphthalene series 3.5kg of high-efficiency water reducer powder, 2.6kg of methyl cellulose ether and other raw materials are subjected to three-dimensional agitation, so that the above-mentioned raw materials are mixed evenly and the polypropylene fibers are fully dispersed, that is, a uniformly mixed dry powder is made.

[0031] 2. Transport 180kg of the uniformly mixed dry powder to a biaxial two-way mixer, and then add B 1 14kg of grade flame-retardant EPS particles and 150kg of water were stirred evenly to prepare the slurry for preparing the composite reinforced waterproof and fireproof insulation board.

[0032] 3. The B 1 The particle size gradation of grade flame-retardant EPS particles is that Φ2mm EPS particles account for 10% of the total weight of the EPS p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com