Interlocking controller for machine tool fixture

A machine tool fixture and controller technology, applied in computer control, program control, general control system, etc., can solve problems such as restricting production and affecting production efficiency, and achieve the effect of improving production efficiency, simple structure and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

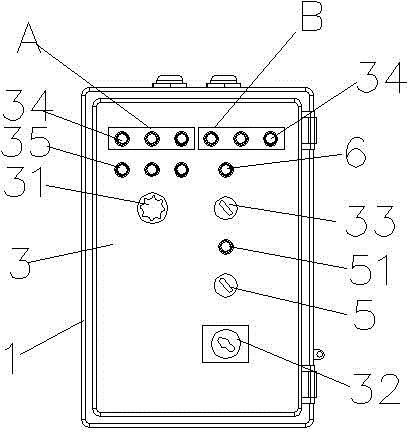

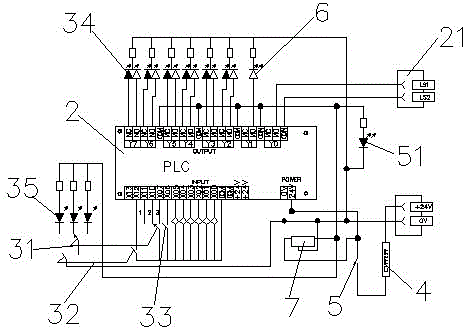

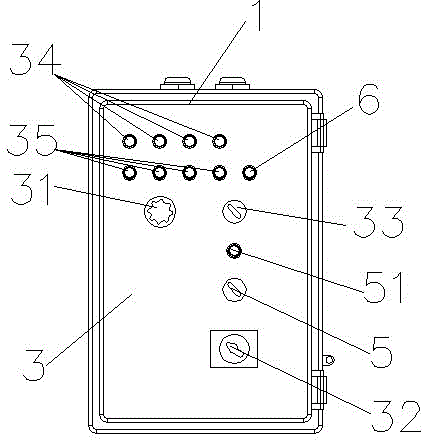

[0022] Figure 1 to Figure 5 Shown is the structural representation of the present invention.

[0023] The reference signs are: No. 1 workbench display area A, No. 2 workbench display area B, controller shell 1, PLC programmable logic controller 2, command signal line 21, control panel 3, band switch 31, Authority switch 32, interlock release switch 33, workbench indicator light 34, band indicator light 35, miniature circuit breaker 4, power switch 5, power indicator light 51, permission indicator light 6, three-terminal voltage regulator 7, electromagnetic sensor 8 , CNC machine tool 9, workbench 91, fixture cylinder 92.

[0024] Such as Figure 1 to Figure 5 As shown, the machine tool clamp interlock controller of the present invention includes a controller housing 1, a PLC programmable logic controller 2 with a locking program inside is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com