Nozzle impinging stream rearrangement reactor

A technology for reactors and nozzles, which is applied in the field of reactors for the preparation of caprolactam by liquid-phase rearrangement reaction using impingement flow technology. It can solve the problems of rearrangement reactions that have not been discovered, solve the serious corrosion of equipment, and reduce the generation of side reaction products. , Improve conversion rate and selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

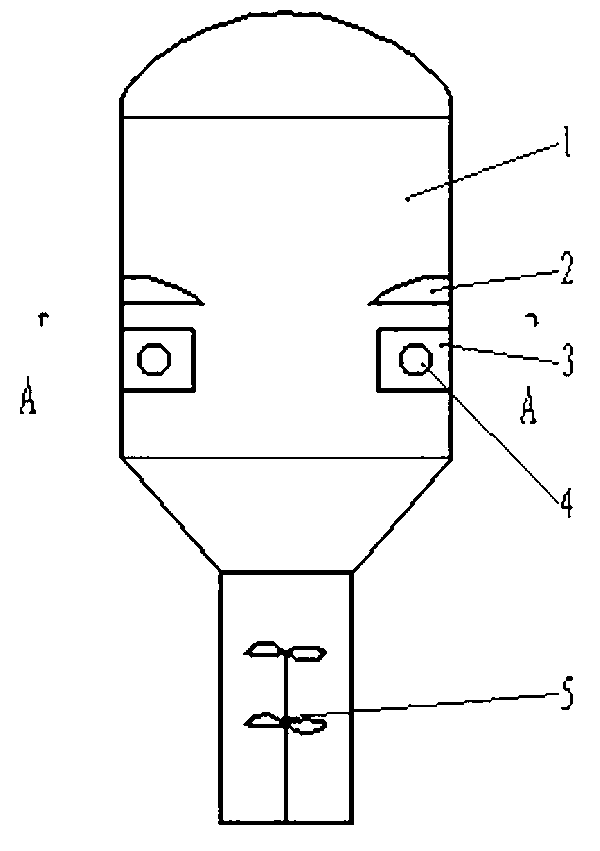

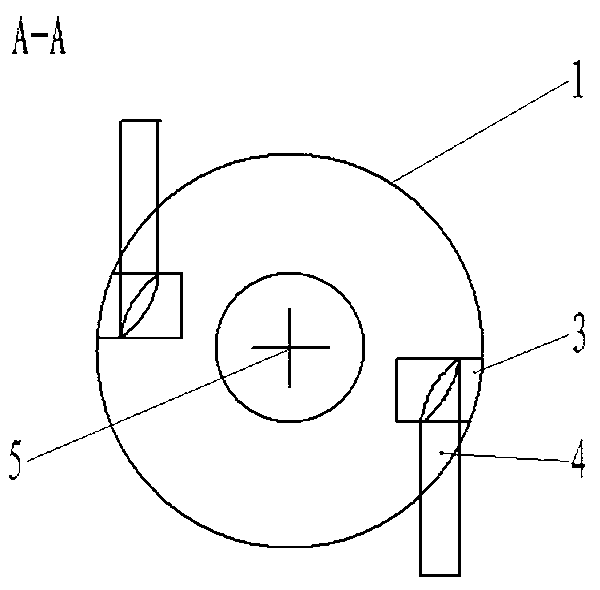

[0018] Nozzle impingement flow rearrangement reactor of the present invention such as figure 1 , figure 2 As shown, it mainly includes a reactor 2, which is provided with an agitator 5 and a nozzle 4 arranged horizontally and symmetrically. The nozzle is installed in a tangential feeding manner, and the agitator is installed at the bottom of the reactor. An upwardly opening immersion impact chamber 3 is provided at the exit of the nozzle, and a defogging cover 2 is arranged above the immersion impact chamber. The outside of the nozzle is connected to the feed line.

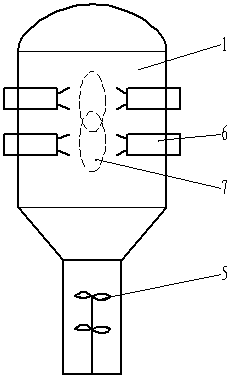

[0019] In order to make full use of the turbulent kinetic energy in the multiphase fluid of the impinging flow technology, strengthen the microscopic mixing between the fluid liquid groups, and strengthen the instantaneous and rapid reaction of the reactants, such as figure 2 As shown, two layers of feed assemblies 6 are arranged in the reactor, and each layer is two pairs of feed assemblies. The two layers of...

Embodiment 2

[0022] Lab implementation. Using the coupling competition series secondary reaction system of α-naphthol (A) and p-aminobenzenesulfonic acid diazonium salt (B, referred to as diazonium salt), the nozzle impingement flow rearrangement reactor of the present invention and the traditional stirred tank reactor Microscopic mixing time is measured, the principle is to determine the reaction time constant through the selectivity of slow reaction products to define the microscopic mixing characteristic time constant .

[0023] The experimental equipment of the present invention and the stirred tank reactor are all made of transparent plexiglass, with an inner diameter of 320 mm, which is about 1 / 10 of the diameter of the actual rearrangement reactor. Among them, four baffles are arranged on the inner wall of the stirred tank reactor, and the width of each baffle is 1 / 10 of the tank diameter, and the stirring paddle is a standard six-bladed Rushton turbine paddle.

[0024] while m...

Embodiment 3

[0027] Industrial Implementation in Caprolactam Rearrangement Process. The operation process is as follows: Dissolve cyclohexanone oxime in n-hexane, then mix the amidation reaction solution and cyclohexanone oxime solution according to the required mass ratio (preferably 0.46:1) and introduce them into the rearrangement reactor for rearrangement reaction. Among them, the preferred flow rate of the amidation reaction solution entering the rearrangement reactor is about 23 t / h, and the feed temperature is preferably 71°C; the preferred flow rate of the cyclohexanone oxime solution is about 50 t / h, and the feed temperature is preferably 61°C. ℃. The pressure of the rearrangement reactor is controlled at slightly positive pressure, the pressure is controlled at about 5 kPa, and the rotational speed of the stirrer is controlled at 80-180 rpm.

[0028] When the traditional rearrangement reactor is used for rearrangement reaction, when the production capacity is 70 kt / a, the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com