Ammonia circulation-based method and device for carbonating fixation of CO2 in coal-fired flue gas

A coal-fired flue gas and carbonation technology, which is applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve problems such as no better treatment or resource recovery methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

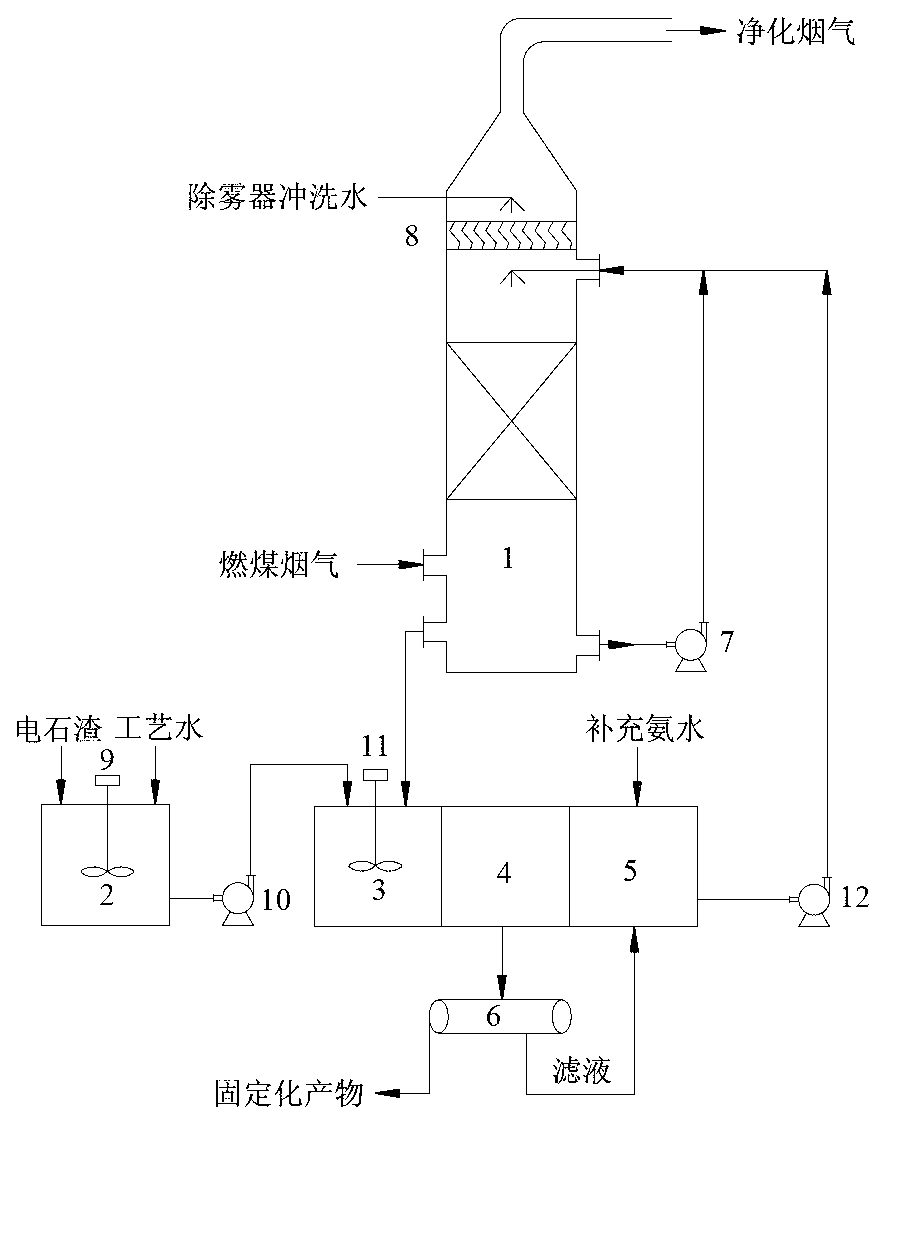

[0046] Contains CO 2 Coal-fired flue gas is produced by a fully automatic coal-fired boiler with a gas volume of 10Nm 3 / h; after dedusting and wet desulfurization, CO in the flue gas 2 The concentration is 13% (V / V), the flue gas temperature is 50°C, it enters a packed absorption tower with a diameter of 100mm, and the ammonia solution with a mass concentration of 10% is used as CO 2 Absorption liquid, gas-liquid countercurrent contact in the absorption tower, the contact time is 5s, the temperature of the ammonia absorption liquid is 40°C, the absorption pressure is normal pressure, and the liquid-gas ratio is 5L / Nm 3 ; On-line test by gas chromatograph, CO 2 The removal rate is 76%; the removal of CO 2 The final purified flue gas leaves the packed absorption tower from the top of the tower after demisting and washing with clean water. Ammonia absorbs CO 2 The generated rich solution containing ammonium bicarbonate and ammonium carbonate components and calcium carbide s...

Embodiment 2

[0048] Ammonia absorbs CO 2 After the slurry obtained by the carbonation reaction between the generated rich liquid and the calcium carbide slag slurry is filtered, the filtrate is directly used as CO without adding ammonia water. 2 Absorption liquid, all the other are the same as embodiment 1; After testing, ammoniacal liquor mass concentration is 8% in the filtrate, CO 2 The removal rate was 62%; the filter residue was dried by thermogravimetric analyzer and XRD test, CaCO 3 Accounted for 83%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com