Scutellarin nanosuspension and preparation method thereof

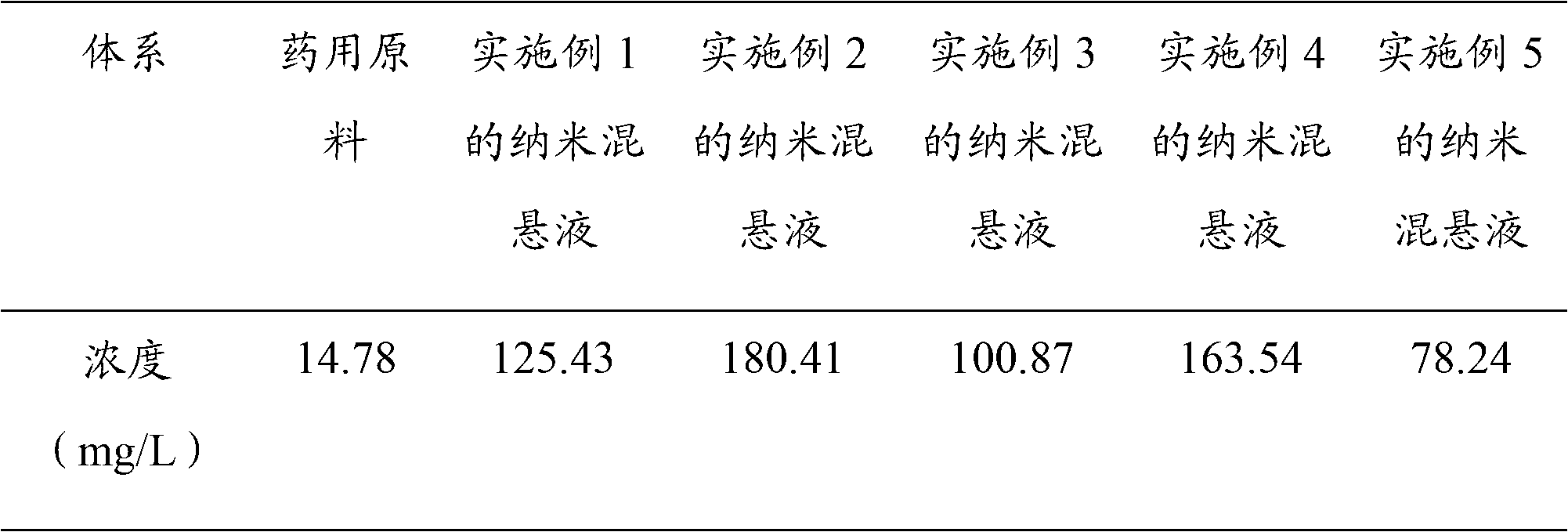

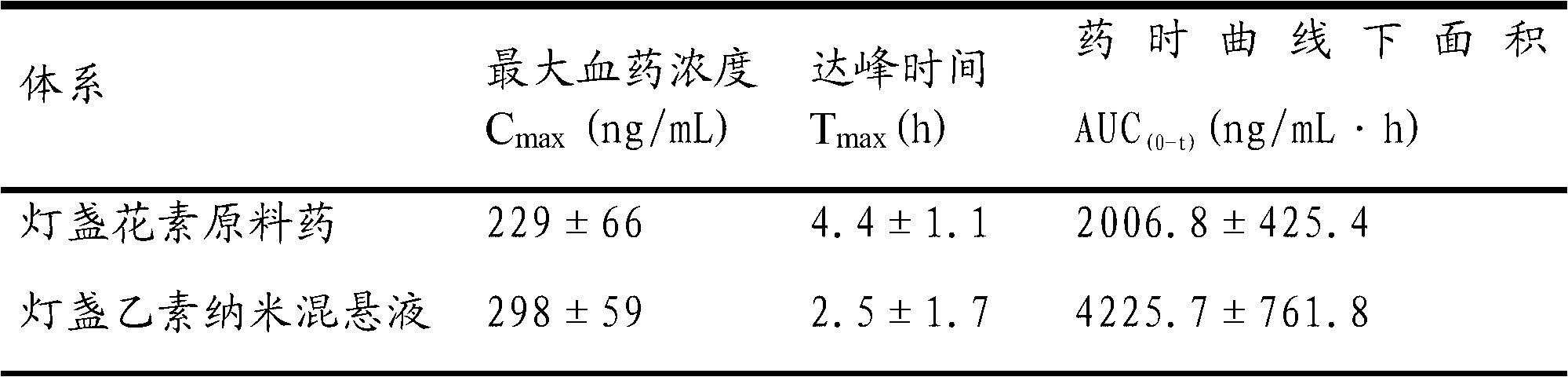

A nano-suspension, scutellarin technology, applied in the directions of liquid delivery, pharmaceutical formulation, emulsion delivery, etc., can solve the problems of organic solvent residue, large polydispersity index, uneven particle size of nano-suspension, etc. The effect of improving availability and increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the scutellarin nanosuspension described in this example, the stabilizer is 1.4g, including 0.8g poloxamer 188 and 0.6g Cremophor EL; scutellarin (purity: 90% (w / w) above) is 0.3g, stabilizer: scutellarin is 4.7:1.

[0024] The preparation method of the scutellarin nanosuspension described in the present embodiment is as follows:,

[0025] (1) Weigh 0.3g scutellarin and dissolve it in 100mL phosphate buffer (pH7.4) as a good solvent;

[0026] (2) Dissolve 0.8g of Poloxamer 188 and 0.6g of Cremophor EL in 100mL of phosphoric acid aqueous solution (pH2.0) as a poor solvent.

[0027] (3) Drop the good solvent into the poor solvent at a dropping rate of 0.5mL / min, stir and disperse with a high-shear mixing emulsifier, control the stirring speed at 100r / min, and continue stirring for 1 hour to form a pre-nanosuspension ;

[0028] (4) Place the pre-nanosuspension in a high-pressure micro-fluidic homogenizer, control the pressure at 800 bar, and circulate 15 times to pre...

Embodiment 2

[0030] In the scutellarin nanosuspension described in this embodiment, the stabilizer is 1g, including 0.4g polyethylene glycol 400 and 0.6g Labrasol; scutellarin is 0.1g, and the stabilizer: scutellarin is 10:1 .

[0031] The preparation method of the scutellarin nanosuspension described in the present embodiment is as follows:

[0032] (1) Weigh 0.1g scutellarin and dissolve it in 100mL sodium hydroxide solution (pH6.8) as a good solvent;

[0033] (2) Dissolve 0.4g polyethylene glycol 400 and 0.6g Labrasol in 100mL hydrochloric acid aqueous solution (pH2.0) as a poor solvent;

[0034] (3) Drop the good solvent into the poor solvent at a dropping rate of 5mL / min, mechanically stir to disperse, and control the stirring speed at 500r / min, after dropping, continue stirring for 30 minutes to form a pre-nanosuspension;

[0035] (4) Place the pre-nanosuspension in a high-pressure micro-fluidic homogenizer, control the pressure at 1500 bar, and circulate 5 times to prepare the nan...

Embodiment 3

[0037] In the scutellarin nanosuspension described in the present embodiment, the stabilizer is 1.5g, including 0.5g hydroxypropyl methylcellulose K100 and 1g Cremophor RH40; scutellarin is 0.2g, and the stabilizer: scutellarin is 7.5:1.

[0038] The preparation method of the scutellarin nanosuspension described in the present embodiment is as follows:

[0039] (1) Weigh 0.2g scutellarin and dissolve it in 100mL potassium hydroxide solution (pH7.5) as a good solvent;

[0040] (2) Dissolve 0.5g of hydroxypropylmethylcellulose K100 and 1g of Cremophor RH40 in 100mL of acetic acid aqueous solution (pH3) as a poor solvent;

[0041] (3) Drop the good solvent into the poor solvent at a dropping rate of 2mL / min, stir magnetically to disperse, and control the stirring speed at 800r / min, after dropping, continue stirring for 45min to form a pre-nanosuspension;

[0042] (4) Place the pre-nanosuspension in a high-pressure micro-fluidic homogenizer, control the pressure at 1000 bar, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com