Hardened aluminum foil for battery collectors

A technology of aluminum hard foil and battery set, applied in the direction of battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of reduced conductivity, achieve the effects of preventing failures, excellent elongation, and preventing foil breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083] As above, the specific mode for carrying out the present invention has been described, and below, the examples in which the effects of the present invention were confirmed are compared with the comparative examples which do not satisfy the elements of the present invention, and will be specifically described. In addition, this invention is not limited to this Example.

[0084] [Preparation of test materials]

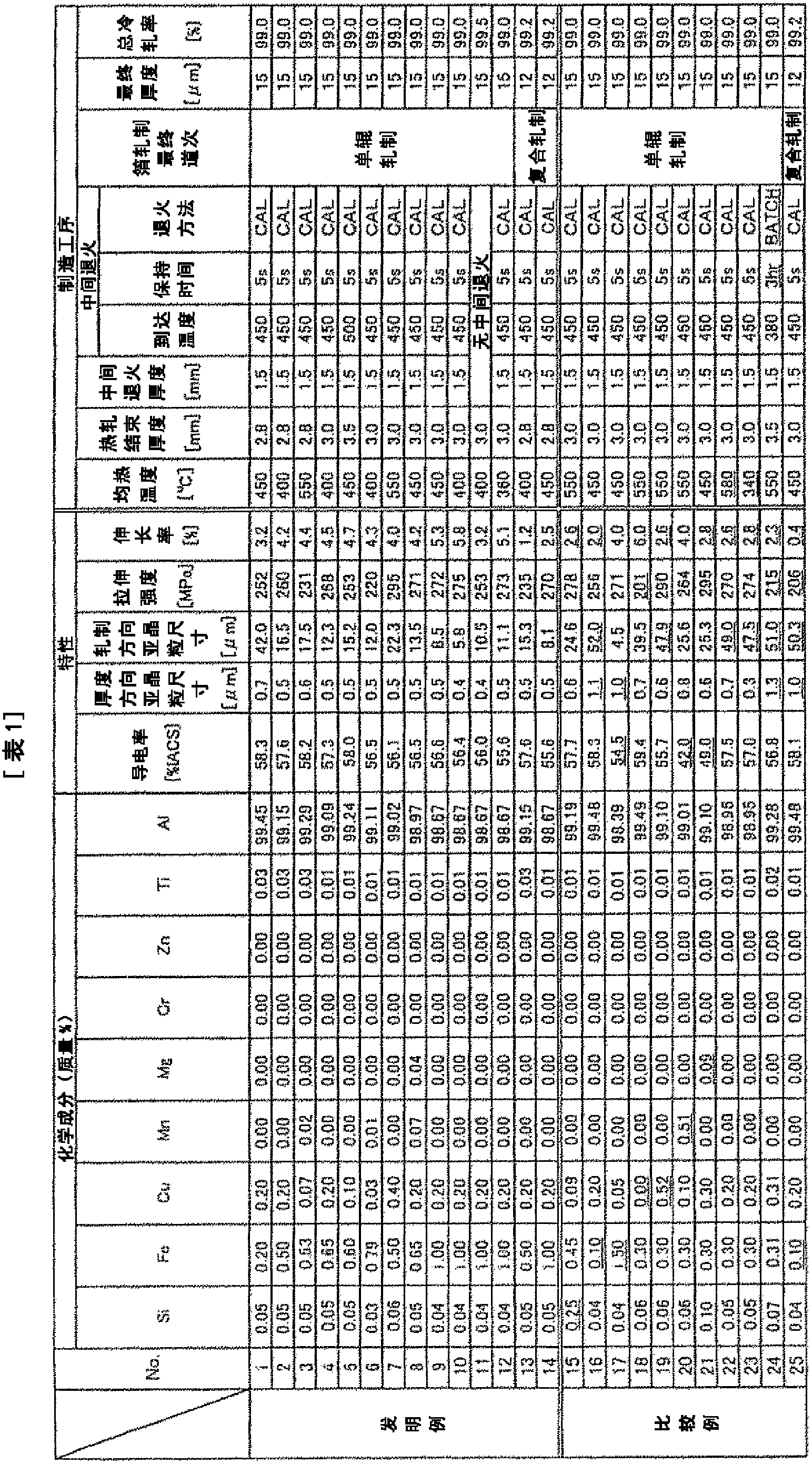

[0085] (Invention Example No.1-14, Comparative Example No.15-25)

[0086] Aluminum having the composition shown in Table 1 was melted and cast to obtain an ingot, and after facing the ingot, a homogenization heat treatment was performed at 360 to 550° C. for 2 to 4 hours. The homogenized ingot is hot-rolled, then cold-rolled, intermediate annealed, and then cold-rolled to a predetermined thickness to form an aluminum foil. The conditions of intermediate annealing and cold rolling are shown in Table 1.

[0087] It should be noted that in the case of continuous a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com