Formula of positive active material for lead-acid power battery and preparation method of positive active material

A positive active material, power battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of operator health hazards, accelerated corrosion of coating equipment, high sulfuric acid density, saving time for paste and improving Utilization, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

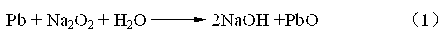

Method used

Image

Examples

Embodiment 1

[0020] A positive electrode active material formula is used to prepare a positive electrode plate. The formula is 80% lead powder, 5% lead tetroxide, Na 2 O 2 5%, CMC 2%, deionized water 3%, sulfuric acid (specific gravity 1.05 g / cm 3 ) 5%; when making the paste, first mix and stir the lead powder, lead tetroxide and sodium peroxide powder for 3 minutes, then add CMC and stir for 5 minutes, then add deionized water, stir for 8 minutes, and finally add 1.05 g / cm 3 The positive electrode plate can be coated by stirring the sulfuric acid for 10 minutes; the coated electrode plate can be dried in a 60 ℃ drying room for 4-6 hours before entering the assembly and battery formation process. The rest of the process can completely use the current valve-controlled sealing lead The production process of acid batteries.

[0021] The prepared plates are assembled into a 12V12Ah valve-regulated sealed lead-acid battery for electric bicycles for performance testing. The 6A discharge time is 13...

Embodiment 2

[0023] A positive electrode active material formula is used to prepare the positive electrode plate. The formula is 70% lead powder, 8% lead tetroxide, Na 2 O 2 8%, CMC 3%, deionized water 5%, sulfuric acid (specific gravity 1.05 g / cm 3 ) 6%; when making the paste, first mix and stir the lead powder, lead tetroxide and sodium peroxide powder for 5 minutes, then add CMC and stir for 8 minutes, then add deionized water, stir for 10 minutes, and finally add 1.05 g / cm 3 The positive electrode plate can be coated by stirring the sulfuric acid for 15 minutes; the coated electrode plate can be dried in a 60 ℃ drying room for 4-6 hours to enter the assembly and battery formation process. The rest of the process can completely use the current valve-controlled sealing lead The production process of acid batteries.

Embodiment 3

[0025] A positive electrode active material formula is used to prepare a positive electrode plate. The formula is 75% lead powder, 5% lead tetroxide, Na 2 O 2 5%, CMC 2%, deionized water 5%, sulfuric acid (specific gravity 1.05 g / cm 3 ) 8%; when making the paste, first mix and stir the lead powder, lead tetroxide and sodium peroxide powder for 4 minutes, then add CMC and stir for 6 minutes, then add deionized water, stir for 9 minutes, and finally add 1.05 g / cm 3 The positive electrode plate can be coated by stirring the sulfuric acid for 12 minutes; the coated electrode plate can be dried in a 60 ℃ drying room for 4-6 hours before entering the assembly and battery formation process. The rest of the process can completely use the current valve-controlled sealing lead The production process of acid batteries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com