Titanium-antimony-tellurium phase-changing material depositing method and preparation method of phase-changing storage unit

A technology of phase-change materials and deposition methods, which is applied in the preparation of phase-change memory cells and the deposition of titanium-antimony-tellurium phase-change materials, which can solve problems such as weak data retention, low crystallization temperature, and high power consumption of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

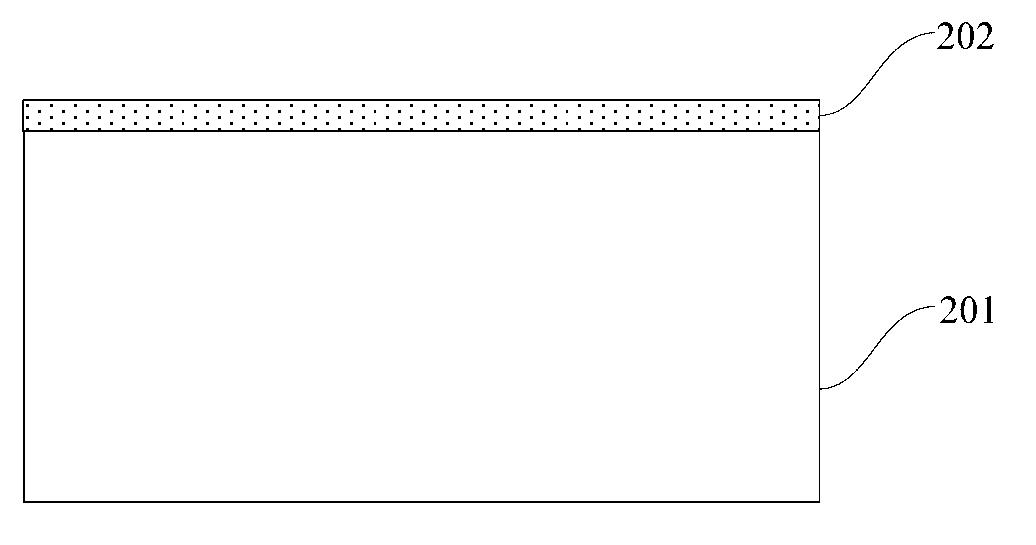

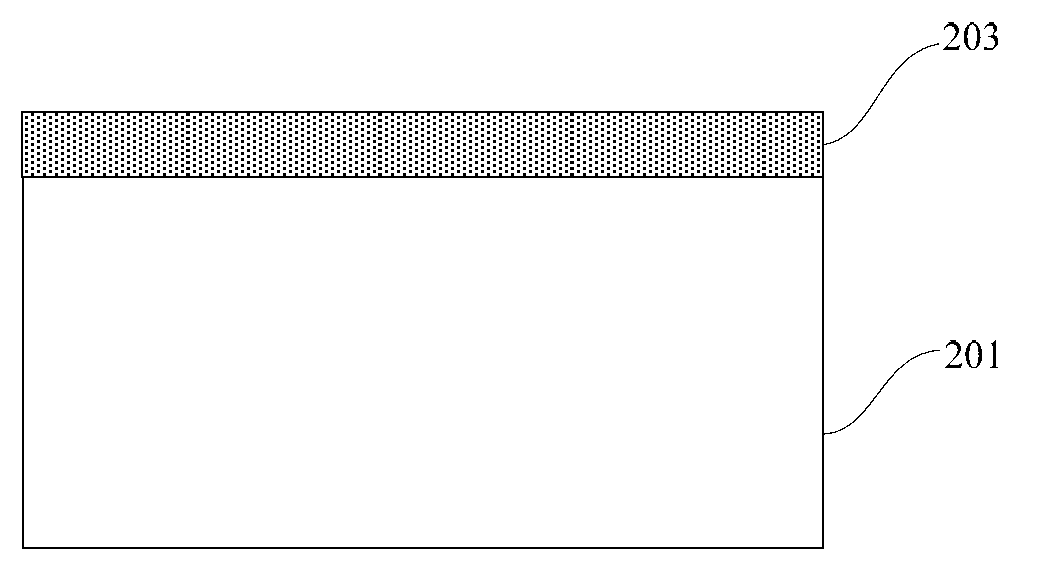

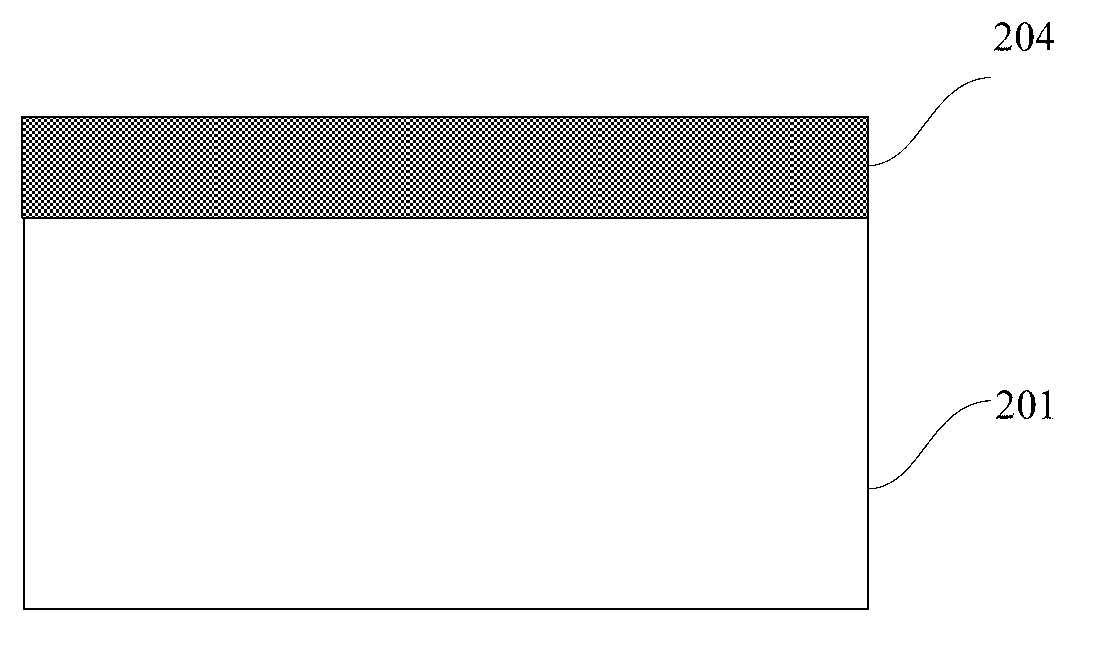

[0053] Such as Figure 1a~Figure 3b As shown, this embodiment provides a titanium-antimony-tellurium phase change material deposition method, at least including the following steps:

[0054] First, a substrate is provided, the substrate is cleaned to remove surface impurities, the substrate is placed in a deposition chamber, and heated to 60-350°C; then the following steps are performed:

[0055] a) Deposition of Ti precursors including (R 1 ) 4 Ti, (R 1 R 2 N) 4 Ti, (R 1 O) 4 Ti, ((R 1 ) 3 Si) 4 Ti and TiM 4 One or more of, where R 1 and R 2 It is a linear, branched or cyclic alkyl group containing 1 to 10 carbons, and M is Cl, F or Br;

[0056] b) Deposition of Te precursors comprising (R 1 ) 2 Te, (R 1 R 2 N) 2 Te, ((R 1 ) 3 Si) 2 One or more than one of Te, wherein R is selected from linear, branched or cyclic alkyl or alkenyl groups containing 1 to 10 carbons;

[0057] c) deposition of Sb precursors, the Sb precursors include (R 1 ) 3 Sb, (R 1 R ...

Embodiment 2

[0064] This embodiment provides a titanium-antimony-tellurium phase-change material deposition method, at least including the following steps: put the substrate into the deposition chamber, first perform a), the Ti precursor Ti(OCH 3 ) 4 Pass through and deposit on the surface of the substrate, and clean the remaining precursor; then proceed to c), pass through the Te precursor ((CH 3 ) 3 Si) 2 Te, and clean the remaining precursors and reaction products, at this time to form TiTe 2 , followed by b), the Sb precursor Sb(OC 2 h 5 ) 3 , and clean the remaining precursor, and then proceed to c) again, passing Te precursor ((CH 3 ) 3 Si) 2 Te, cleaning the remaining precursors and reaction products, at this time a layer of Sb is formed 2 Te 3 , according to the deposition sequence a)-c)-b)-c) cycles to finally form the titanium-antimony-tellurium phase change material layer. The composition of the titanium-antimony-tellurium phase change material layer can be controlled...

Embodiment 3

[0066] This embodiment provides a titanium-antimony-tellurium phase-change material deposition method, at least including the following steps: put the substrate into the deposition chamber, first perform b), and introduce the Sb precursor Sb(C 3 h 7 ) 3, and clean the remaining precursor, and pass in hydrogen plasma for a certain period of time (such as 2s); then proceed to c), and pass in Te precursor Te(C 3 h 7 ) 2 , and clean the remaining precursor, and pass through hydrogen plasma for a certain period of time (such as 2s); then proceed to a), the Ti precursor Ti(C 4 h 9 ) 4 Pass through the deposition on the surface of the substrate, and clean the remaining precursor, pass through the hydrogen plasma for a certain period of time (such as 2s); then perform a) again, the Ti precursor Ti(C 4 h 9 ) 4 Pass through the deposition on the surface of the substrate, and clean the remaining precursor, pass through the hydrogen plasma for a certain period of time (such as 2s)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com