Two-degree-of-freedom nanometer positioning platform

A nano-positioning and degree-of-freedom technology, applied in optics, opto-mechanical equipment, instruments, etc., can solve problems such as uneven distribution of imprinting force, limitation of processing accuracy and quality, easy stretching and deformation of silica gel, etc., to achieve micro-feeding and Precise positioning, non-linearity elimination, assembly-free effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

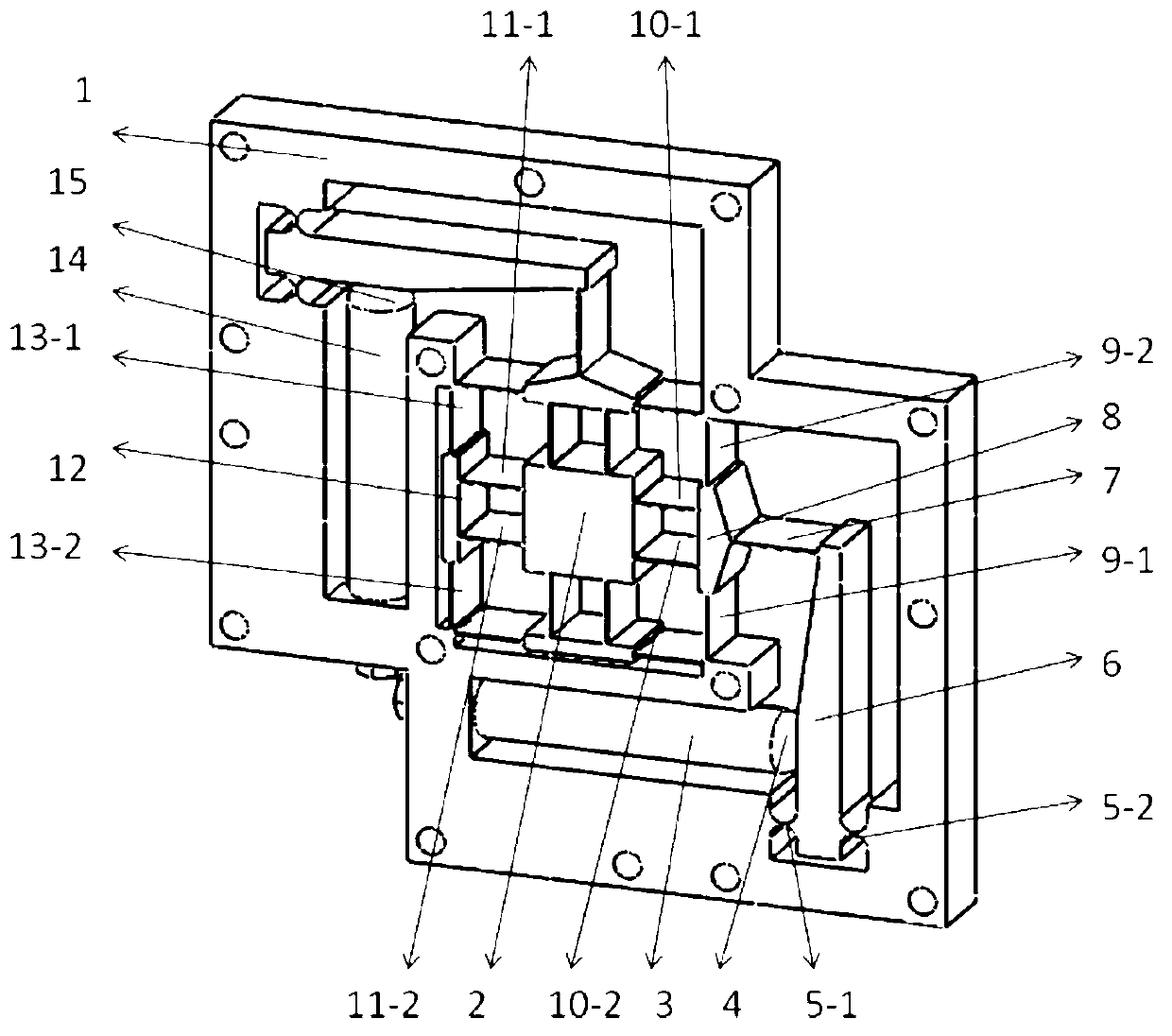

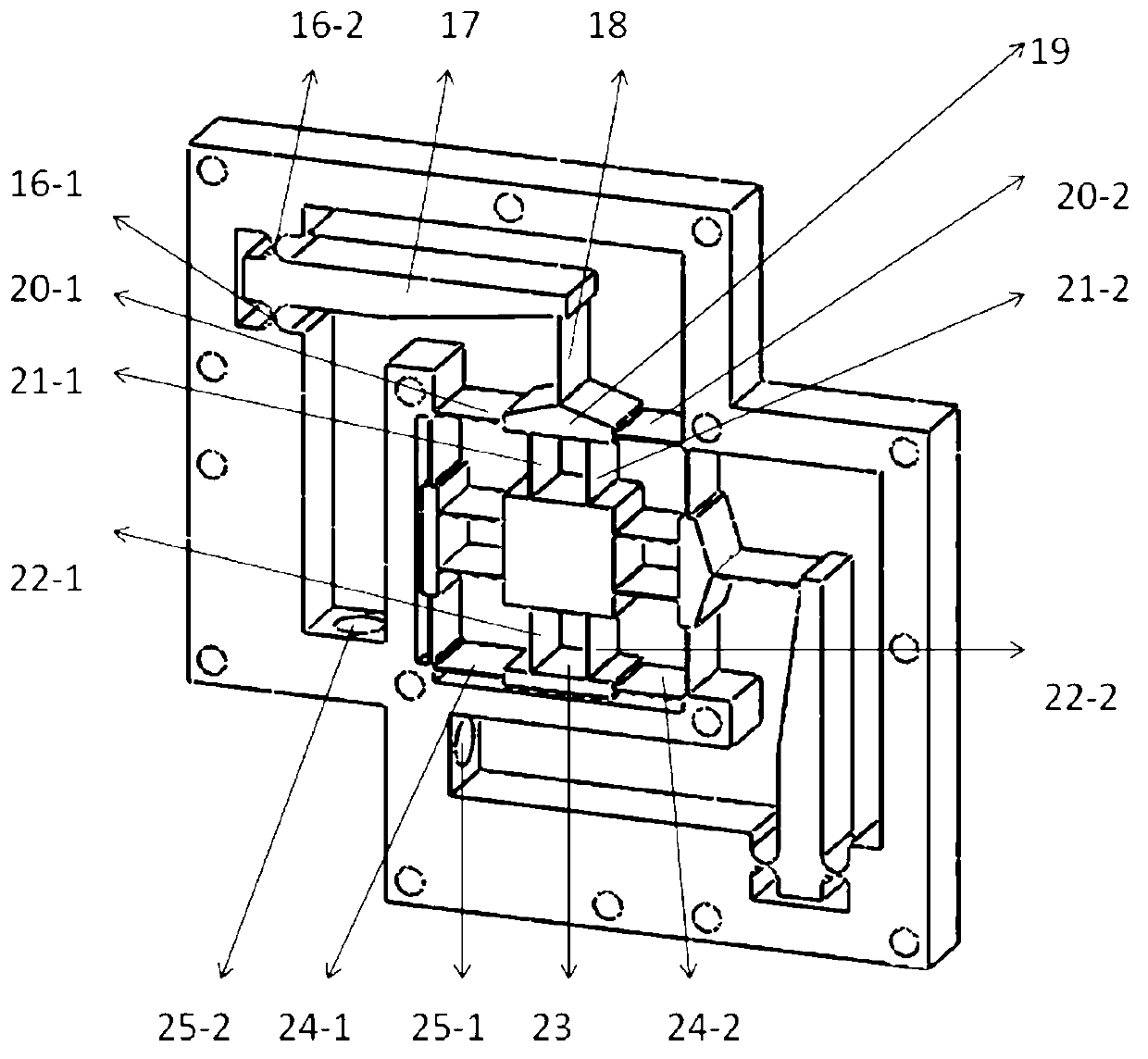

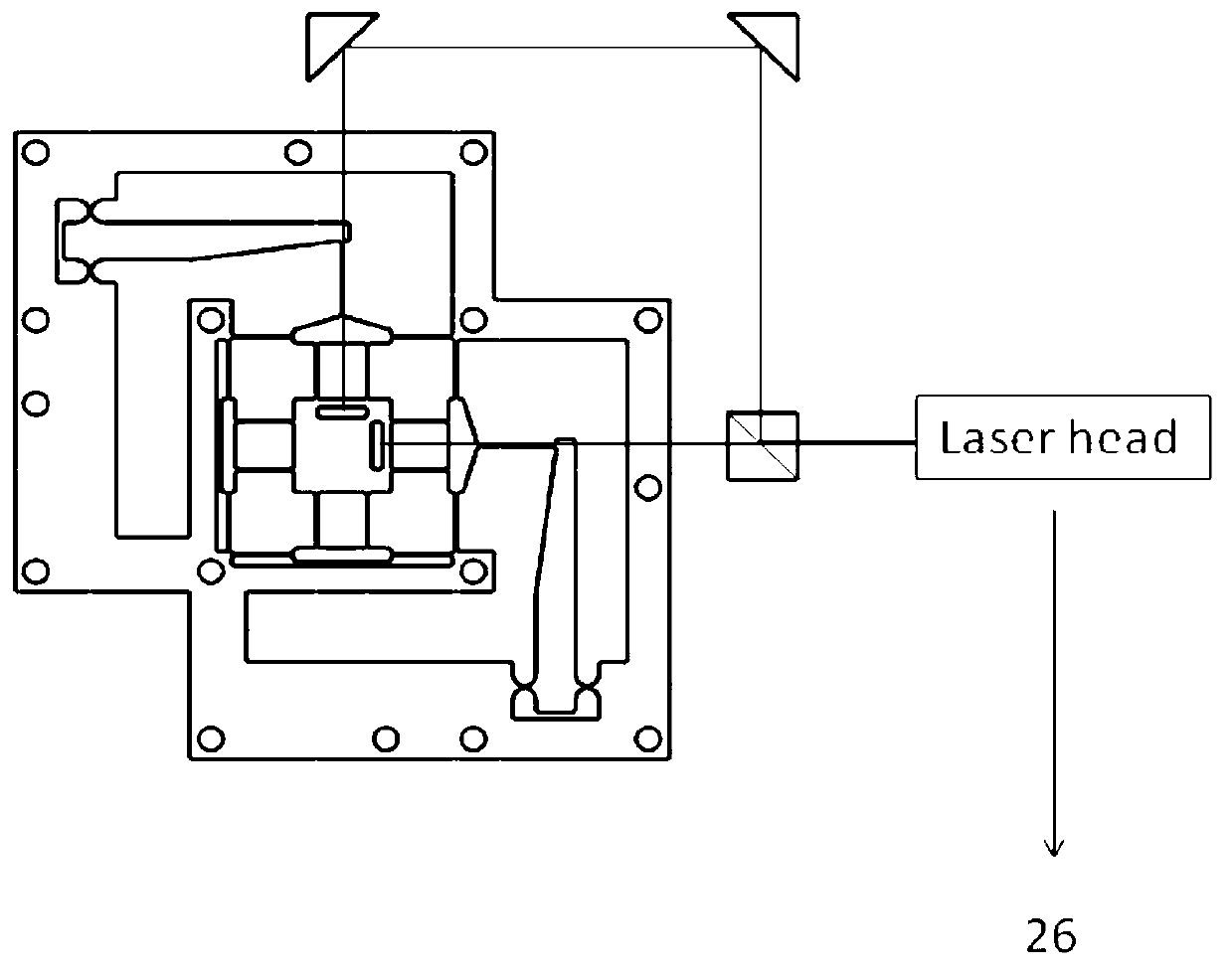

[0021] see Figure 1 to Figure 3 , a two-degree-of-freedom nano-positioning platform, comprising a moving platform 2 and a base 1, the moving platform 2 and the base 1 are connected by flexible branches in the X-axis direction and flexible branches in the Y-axis direction.

[0022] The flexible branch chain in the X-axis direction includes a piezoelectric ceramic driver 3 arranged in a direction parallel to the X-axis, a displacement amplifying lever 6 arranged in a direction parallel to the Y-axis, a first moving block 8 and a second moving block 12 .

[0023] The piezoelectric ceramic driver 3 arranged in the direction parallel to the X axis is placed horizontally, and a ball joint 4 is installed at the top, and the ball joint 4 is in contact with the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com