Camera module and camera module assembly method

A camera module and assembly method technology, applied to the camera body, camera, installation, etc., can solve the problems of the lens deviating from the focus position, high requirements for back focus, and reducing the assembly efficiency of the camera module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

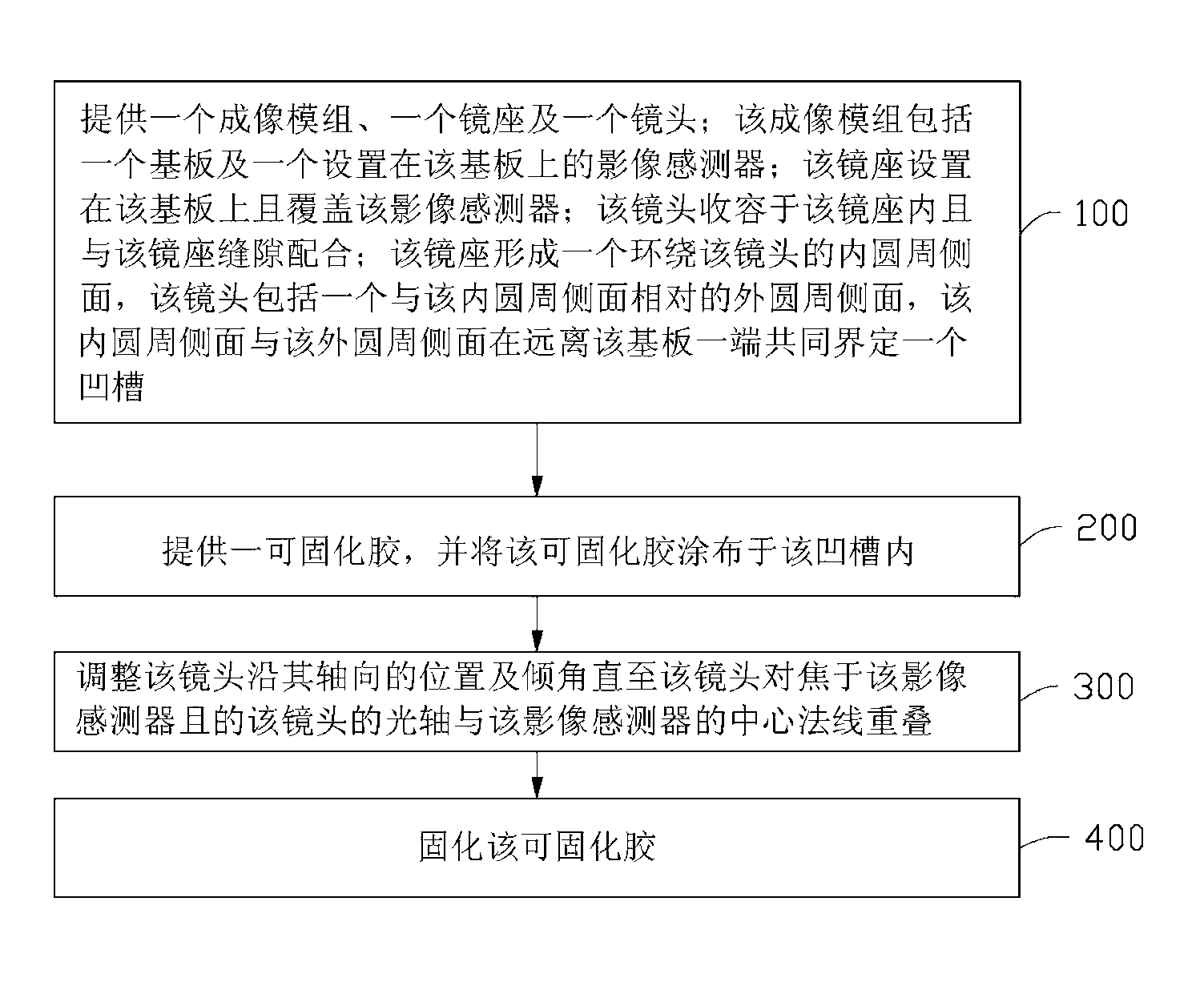

[0026] see figure 1 and figure 2 , the camera module assembly method of the first embodiment of the present invention includes:

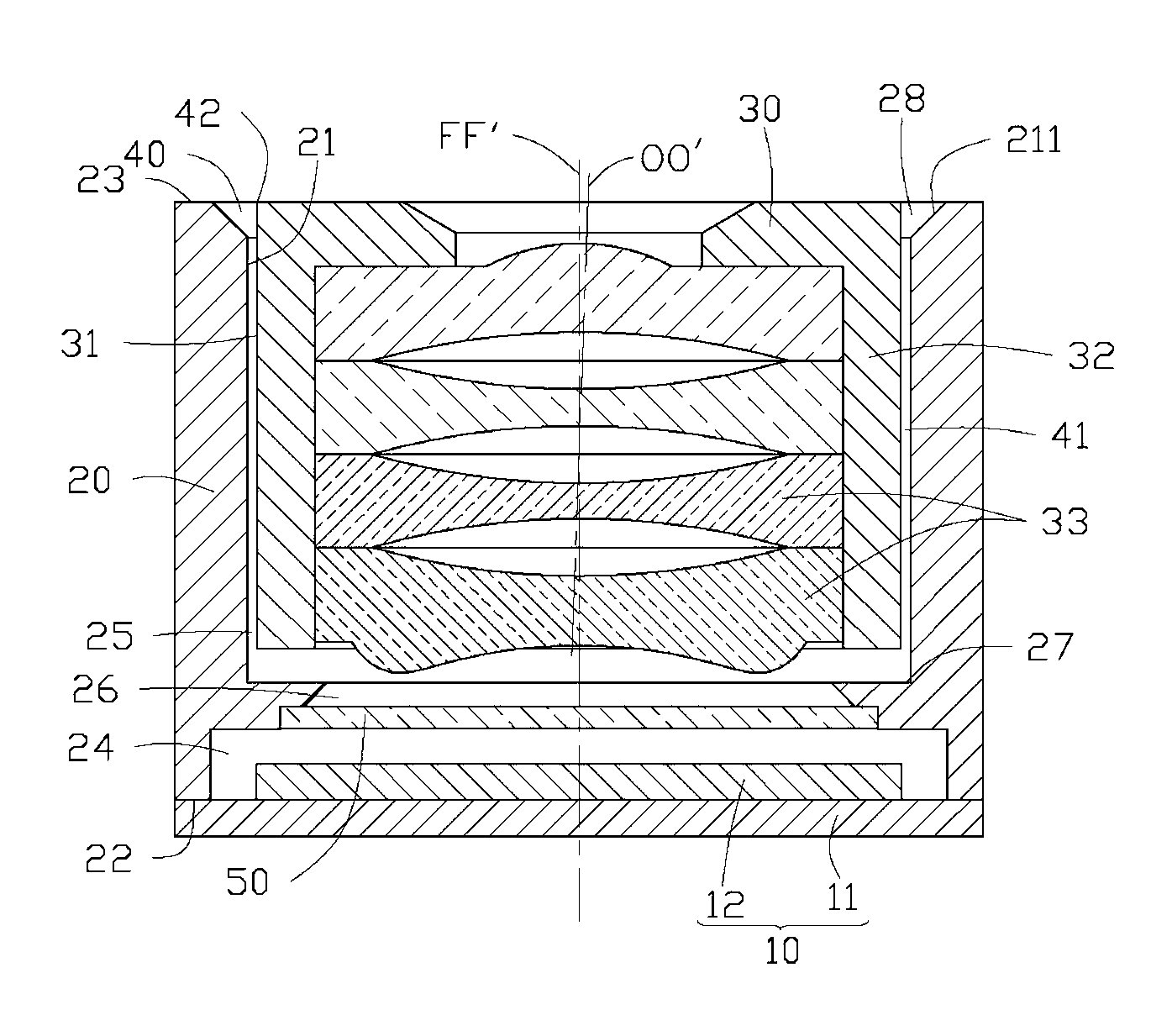

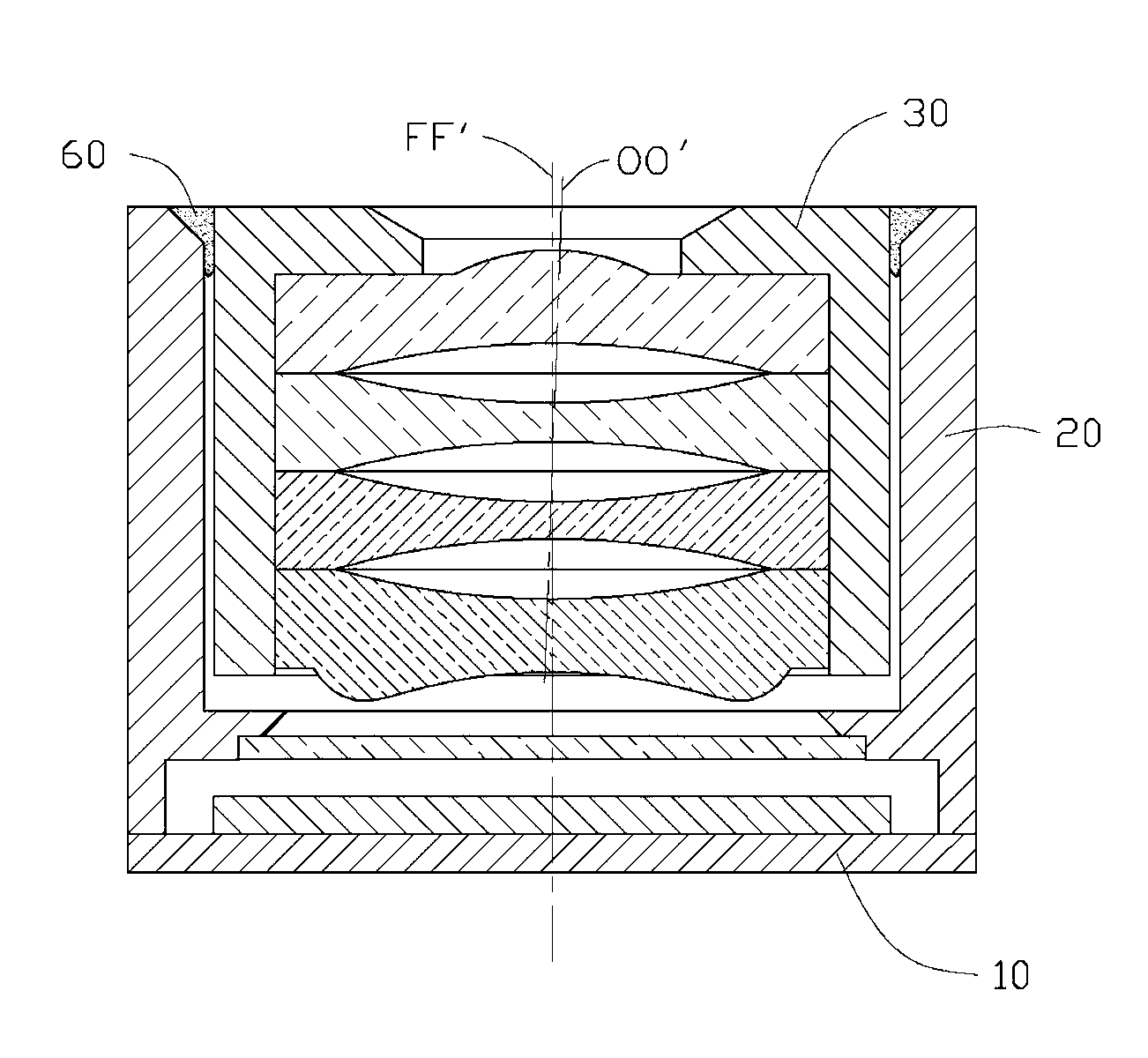

[0027] Step 100 : providing an imaging module 10 , a lens mount 20 and a lens 30 . The imaging module 10 includes a substrate 11 and an image sensor 12 disposed on the substrate 11 . The mirror base 20 is disposed on the substrate 11 and covers the image sensor 12 . The lens 30 is accommodated in the mirror holder 20 and fits in a gap with the mirror holder 20 . The mirror holder 20 includes an inner peripheral side 21 surrounding the lens 30 , the lens 30 includes an outer peripheral side 31 opposite to the inner peripheral side 21 , the inner peripheral side 21 and the outer peripheral side 31 are away from the substrate 11 The ends together define a groove 40 .

[0028] Specifically, the mirror base 20 includes an image-side end surface 22 attached to the substrate 11 and an object-side end surface 23 opposite to the image-side end surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com