Anti-static high-gloss flame-retardant PBT/ABS composite material and preparation method thereof

A composite material and high-gloss technology, applied in the field of polymer materials, can solve the problems of reducing the physical and mechanical properties of ABS resin, reducing the surface gloss of ABS resin, etc., and achieve the effect of good comprehensive mechanical properties, good dimensional stability and high flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

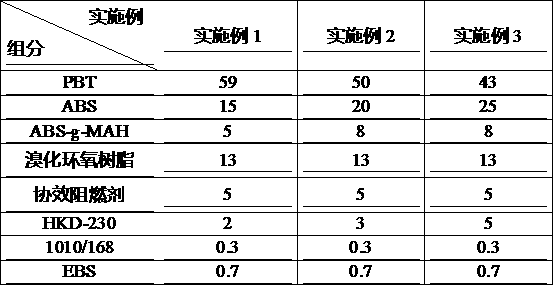

[0020] The present invention is further explained below in conjunction with the examples, but the examples do not limit the present invention in any form.

[0021] First, accurately weigh the prepared raw materials according to the raw material components of each embodiment in Table 1; then put all the above-mentioned raw materials into a high mixer and mix them for 2-5min before discharging; put the mixed raw materials into the twin-screw extruder In the feeding hopper, it is melt-extruded and granulated. The processing technology is as follows: Twin-screw extruder zone 1 180-200°C, zone 2 215-240°C, zone 3 215-240°C, zone 4 200-230°C, zone 5 Zone 200-230°C, zone six 215-240°C, zone seven 215-240°C, zone eight 215-240°C; screw speed controlled at 350r / min; residence time at 2-10min.

[0022] The various performance tests of each embodiment of the antistatic high light flame retardant PBT / ABS composite material of the present invention are as shown in Table 2:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com