Method for decoloring cephalosporin

A cephalosporin and anion technology, which is applied in the field of cephalosporin preparation, can solve the problems of high price, heavy pollution, high environmental protection pressure of acetic acid waste liquid, etc., and achieves the advantages of saving raw material cost, prolonging economic benefit and saving environmental protection treatment cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for decolorizing cephalosporins, comprising the following steps:

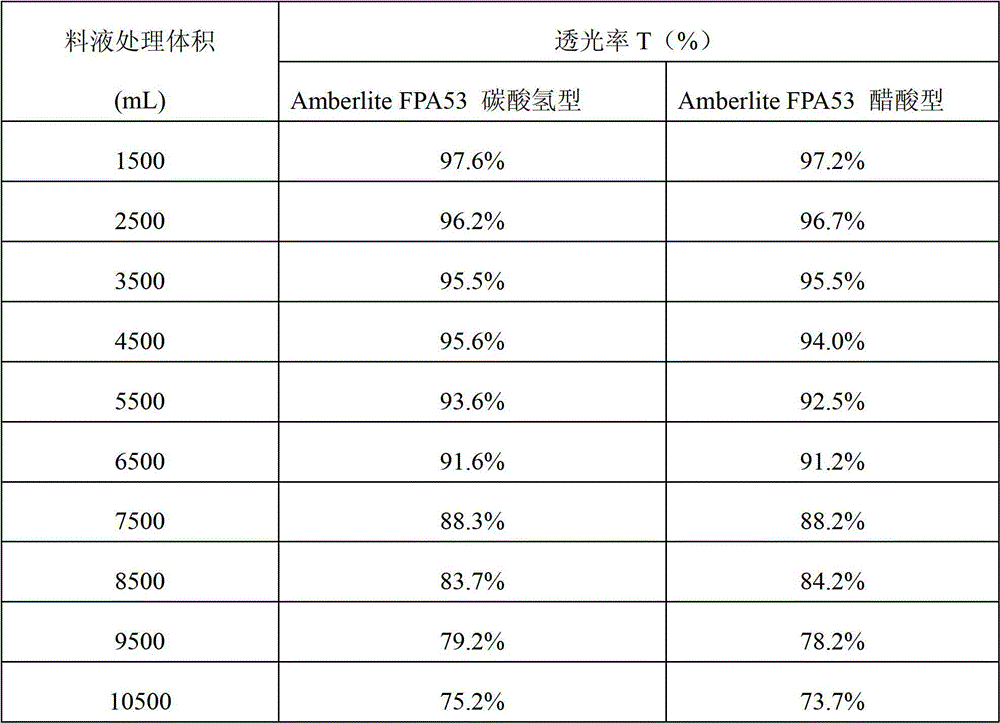

[0033] 1) Resin transformation

[0034] Take 100mL of Amberlite FPA53 (polyacrylic acid skeleton, the functional group is tertiary amine, and the factory ion form is free hydroxyl) for column packing, and convert them into bicarbonate form and acetic acid form respectively.

[0035] Specifically, taking the bicarbonate type as an example, first pass 400mL of 1.0mol / L sodium bicarbonate solution from the lower end of the Amberlite FPA53 chromatographic column at a flow rate of 4BV / h; then pass 500mL of deionized water from the upper end of the chromatographic column Washing, flow rate 5BV / h, obtain bicarbonate type resin after washing is completed.

[0036] The transformation method of the acetic acid type is basically the same as the above-mentioned steps, only need to change the above-mentioned 1.0mol / L sodium bicarbonate solution into a 1.0mol / L acetic acid solution.

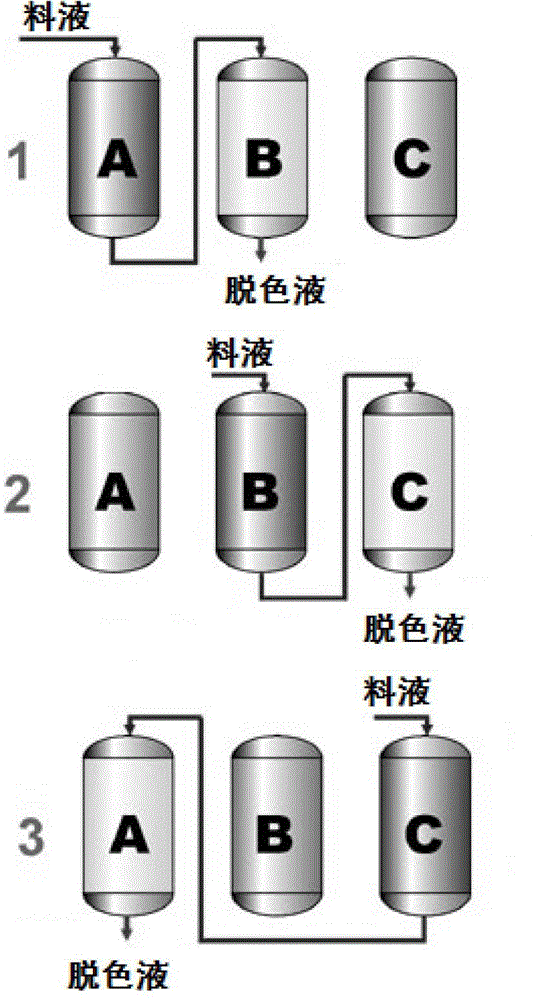

[0037] 2) Decolorizati...

Embodiment 2

[0046] Acetic acid resin was still used as a control.

[0047] 1) Resin transformation

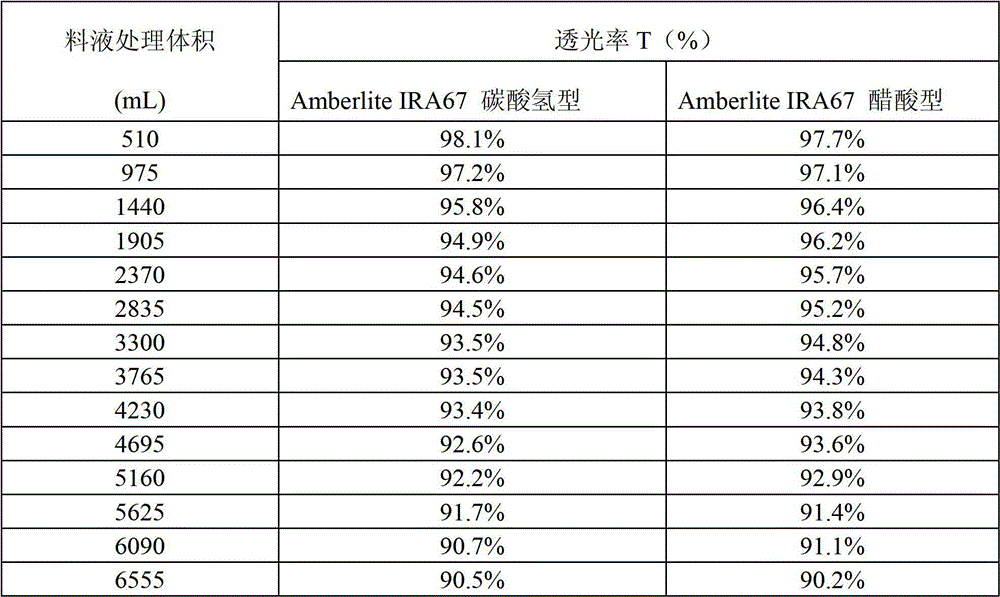

[0048] Each 100mL Amberlite IRA67 was packed into a column, and converted into bicarbonate form and acetic acid form respectively.

[0049] Specifically, taking the bicarbonate type as an example, first pass 250mL of 1.5mol / L ammonium bicarbonate solution from the lower end of the Amberlite IRA67 chromatography column at a flow rate of 2.5BV / h; then pass 600mL of deionized Wash with water at a flow rate of 6BV / h. After the washing is completed, bicarbonate-type resin is obtained.

[0050] The conversion method of the acetic acid type is basically the same as that of the bicarbonate type, and only needs to change the above-mentioned 1.5mol / L ammonium bicarbonate solution into a 1.5mol / L acetic acid solution.

[0051] 2) Decolorization of feed liquid

[0052] The macroporous adsorption resin desorption solution with a light transmittance of 67.4% (light transmittance detection is the same a...

Embodiment 3

[0061] 1) Decolorization of feed liquid

[0062] The macroporous adsorption resin desorption liquid 5000mL of light transmittance 64.3% flows through the resin column decolorization of the Amberlite FPA53 bicarbonate type after the regeneration of embodiment 1, transformation after the flow velocity of 15BV / h, collects the decolorization of cephalosporin at column outlet liquid.

[0063] 2) Regeneration and transformation of resin

[0064] During regeneration, first pass 500mL of 0.5mol / L NaOH solution into the failed resin column layer at a flow rate of 2BV / h, and then wash with deionized water until the pH of the effluent is about 9.5. During transformation, 500mL of 1.0mol / L potassium bicarbonate solution was used to flow through the resin bed at a flow rate of 3BV / h, and finally washed with 1000mL deionized water at a flow rate of 10BV / h.

[0065] At this point, the resin has completed regeneration and transformation, and can be directly used for the next batch of decolo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com