Quartz crucible heating, coating, and packaging integral machine

A technology of quartz crucible and heating coating, applied in packaging, spraying device and other directions, can solve problems such as surface modification of quartz crucible, and achieve the effects of strong liquid adhesion, prevention of heat loss and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

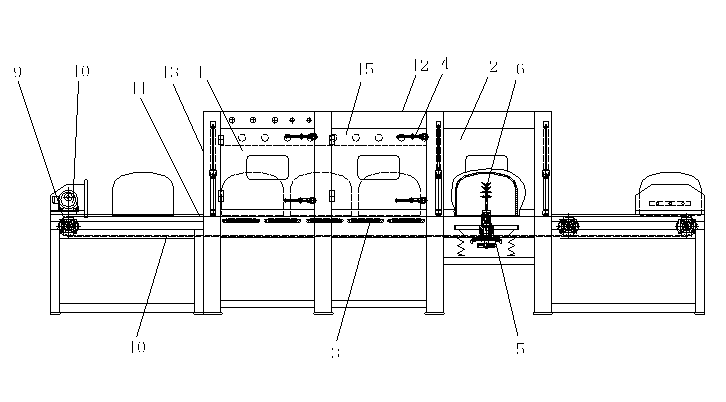

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0013] Such as figure 1 and 2 Shown: a quartz crucible heating coating packaging machine, including a quartz crucible transmission system, and a heating system, a spraying system and a packaging system arranged in sequence according to the transmission direction; the heating system includes a sealable heating room 1 , the heating room 1 is provided with an infrared heating tube 3 and a temperature sensor 4 for a constant temperature, and the spraying system includes a sealable coating room 2, and the coating room 2 is provided with a rotary joint 5 that can be automatically lifted and nozzle 6, the packaging system is made up of negative pressure adsorption manipulator 7 placed on the top and side of the quartz crucible, and the transmission system includes a servo motor 8, a sprocket wheel 9, a chain 10 and a conveyor belt 11 as a power source, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com