Sheet-glass tank furnace structure with independent clarifying part and adjusting method thereof

A flat glass and adjustment method technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of large total expansion, danger, and long length of furnace parts, etc., and achieve length reduction and large production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

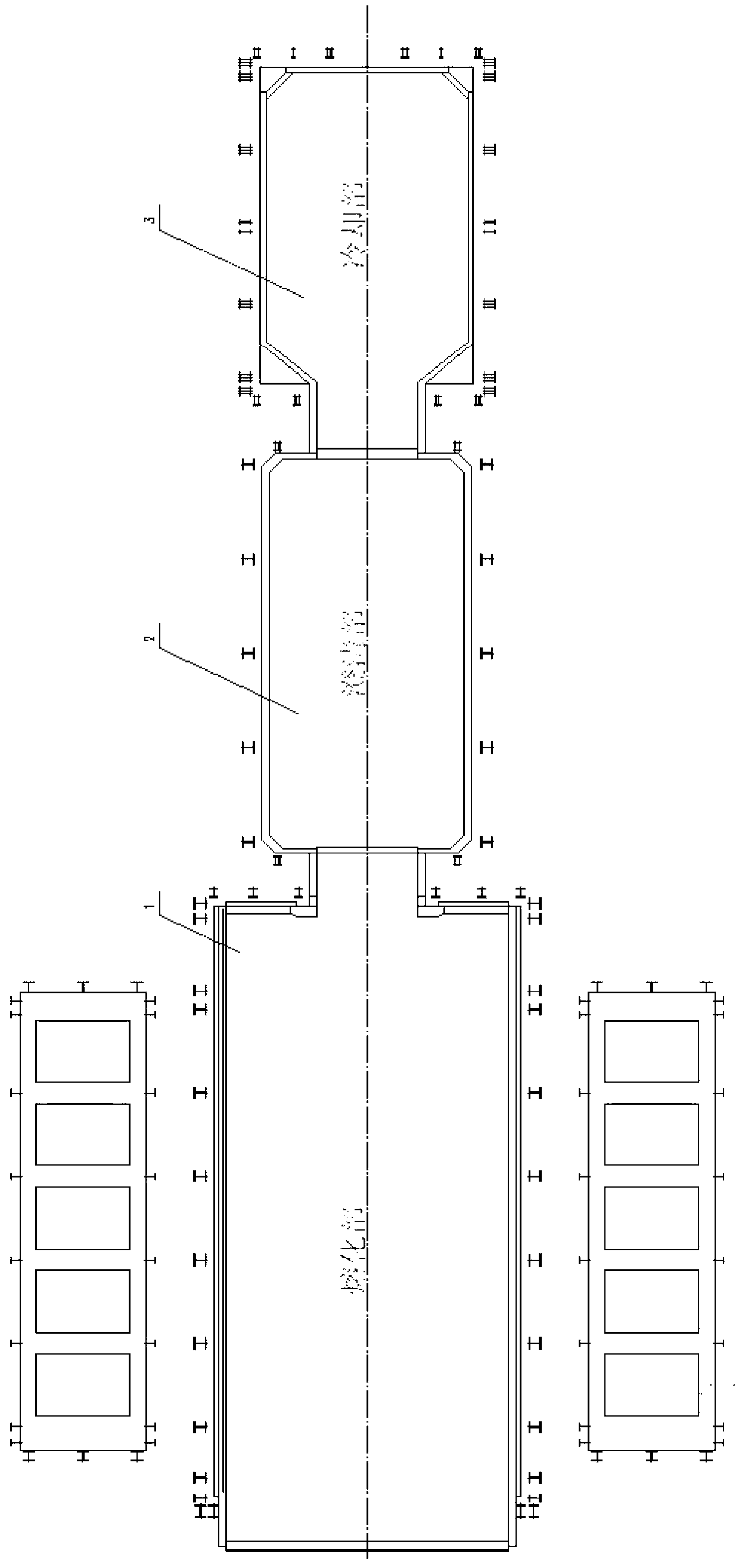

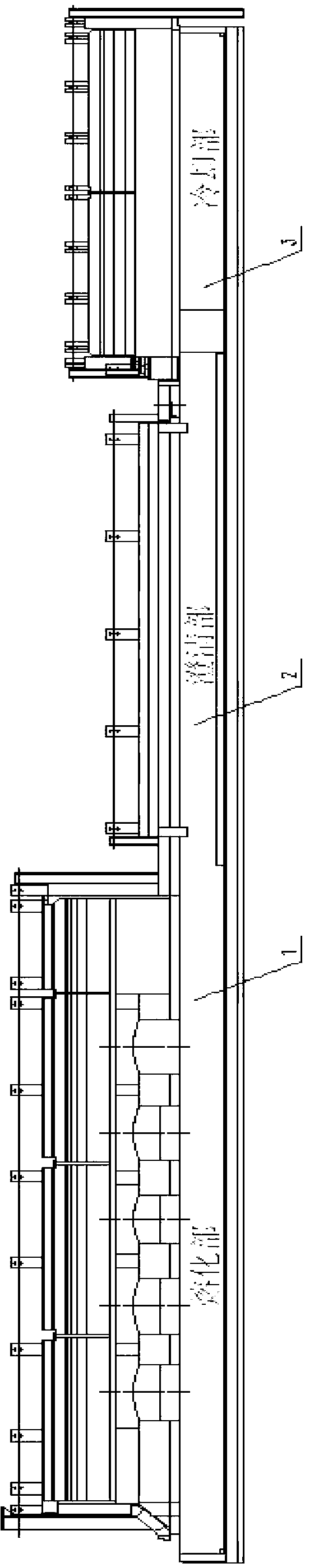

[0024] The pool kiln designed by this patent and the traditional glass pool kiln are both composed of a melting part 1, a clarification part 2, a cooling part 3 and a neck. The differences are as follows: figure 1 and figure 2 As shown, the two parts of the melting part 1 and the clarification part 2 are independent and separated from each other.

[0025] The clarification part 2 is a closed structure formed by the steel structure supporting the refractory material. In the space above the glass liquid inside the clarification part 2, the inlet and outlet are separated from the front and rear spaces by a water bag or a partition wall; in order to adjust the clarification part 2. The temperature inside the clarification part 2 is provided with an electric heating device to adjust the temperature of the clarification part; in order to adjust the air pressure inside the clarification part 2, a mechanical ventilation device and a mechanical air supply device are arranged inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com