Acidifier for piglet feed, and preparation method thereof

A piglet feed and manufacturing method technology, applied in animal feed, animal feed, application, etc., can solve the problems of active ingredients with low melting point, affecting the secretion of gastric acid and pepsin, low cost performance, etc., so that it is not easy to volatilize and lose, and ensure health and full, reduced chance of contact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Formula:

[0050] Phosphoric acid: 30%, lactic acid: 15%, fumaric acid: 8%, citric acid: 6%, calcium formate: 5%, white carbon black: 10%, calcium hydrogen phosphate: 10%, stearic acid: 16%,

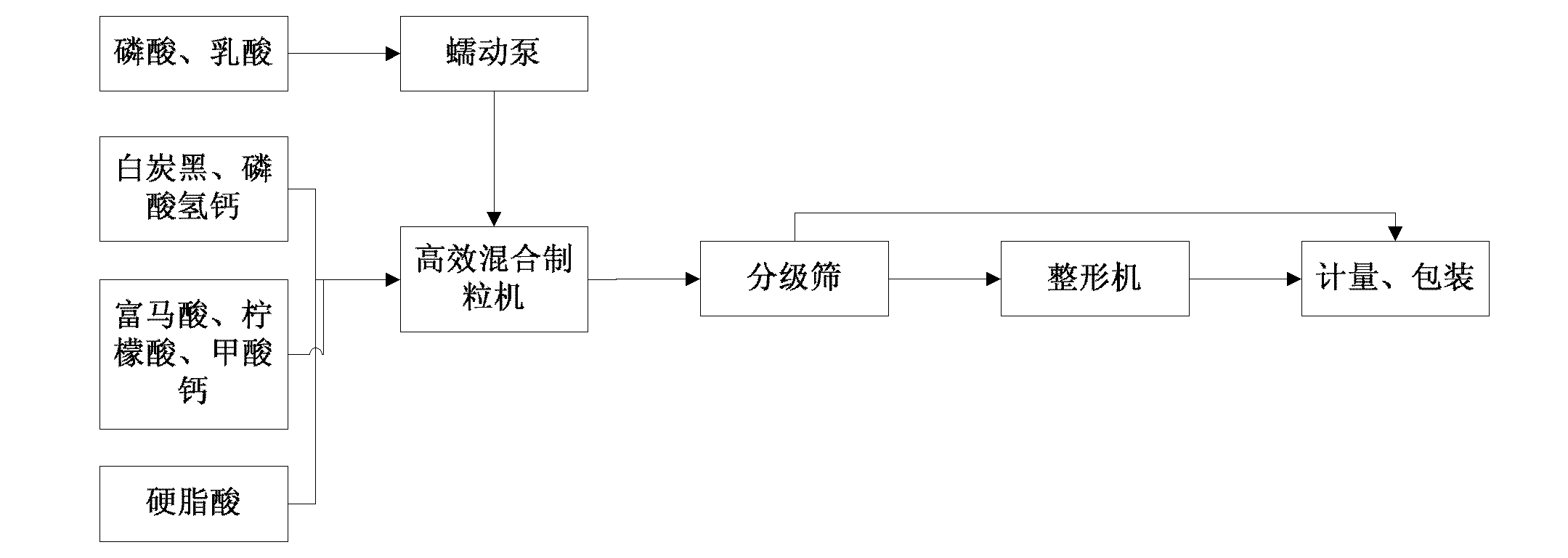

[0051] 2, processing method: technological process of the present invention is as figure 1 As shown, the equipment used is as figure 2 As shown, it specifically includes the following steps:

[0052] 1) Material preparation:

[0053] Add the liquid acid (phosphoric acid, lactic acid) into the liquid tank A according to the formula, and set aside;

[0054] Add white carbon black and calcium hydrogen phosphate to the material bin B1 according to the formula requirements, and set aside;

[0055] Add stearic acid into the material bin B2 according to the formula requirements, and set aside;

[0056] Add citric acid, fumaric acid and calcium formate into the material bin B3 according to the formula requirements, and set aside.

[0057] 2) Adsorption and mixing:

[0058] Turn...

Embodiment 2

[0075] 1. Formula:

[0076] Phosphoric acid: 40%, lactic acid: 8%, fumaric acid: 5%, citric acid: 5%, calcium formate: 5%, white carbon black: 11%, calcium hydrogen phosphate: 6%, stearic acid: 20%,

[0077] 2, processing method: with embodiment 1.

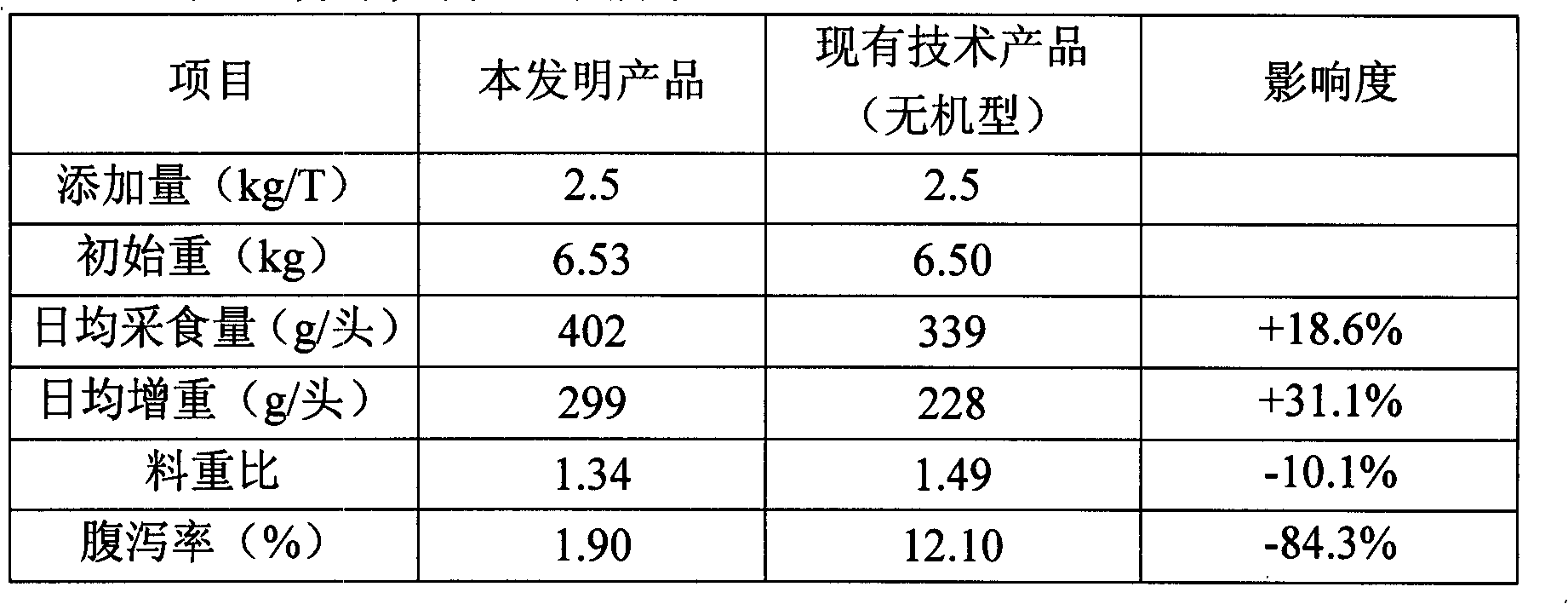

[0078] 3. The use effect is shown in the table below

[0079] project

Embodiment 3

[0081] An acidifier for piglet feed, comprising the following components and weight percentages: phosphoric acid: 25%, lactic acid: 8%, fumaric acid: 7%, citric acid: 5%, calcium formate: 5%, white carbon black: 15%, calcium hydrogen phosphate: 15%, stearic acid: 20%.

[0082] The manufacture method of acidifier for piglet feed comprises the following steps:

[0083] (1) Prepare materials according to the above components and weight percentage content:

[0084] (2) Material preparation:

[0085] Phosphoric acid and lactic acid, white carbon black and calcium hydrogen phosphate, stearic acid, citric acid, fumaric acid and calcium formate are respectively placed in four material bins according to the formula for standby;

[0086] (3) Adsorption and mixing:

[0087] a. Turn on the turntable of the mixing granulator, add white carbon black and calcium hydrogen phosphate to the mixing granulator for mixing,

[0088] b. Phosphoric acid and lactic acid are added to the mixing gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com