Packaging structure for ultraviolet luminous diode

A light-emitting diode and packaging structure technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of not being able to adapt to harsh application environments, poor stability, and poor airtightness, so as to avoid device aging, good airtightness, and Strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

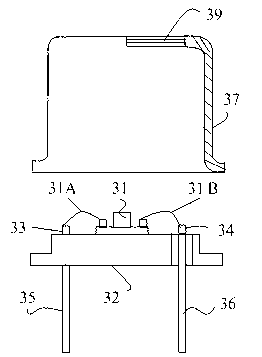

[0030] Embodiment 1. In order to improve the airtightness of the ultraviolet light-emitting diode package and the ability to resist various harsh environments, this embodiment proposes a new packaging structure for the light-emitting chip 31 that emits ultraviolet light. See image 3 As shown, it includes a TO type metal socket 32 and a metal cap 37. At least two pins are provided on the metal tube base 32 , respectively defined as positive pins 35 and negative pins 36 , which are respectively connected to the tube base electrodes 33 and 34 correspondingly. The socket electrodes 33, 34 are respectively connected to the positive and negative electrodes of the light-emitting chip 31 through a wire 31A, 31B (preferably gold wire), so that the positive and negative electrodes of the light-emitting chip 31 pass through the pins of the metal socket 32. 35 and 36 lead out to realize the indirect connection between the light-emitting chip 31 and the external power supply, and contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com