Ultrahigh voltage anode foil corrosion method for aluminum electrolytic capacitor

An aluminum electrolytic capacitor, ultra-high voltage technology, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of small holes in the anode foil, low specific volume, and inability to achieve the effect of low leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

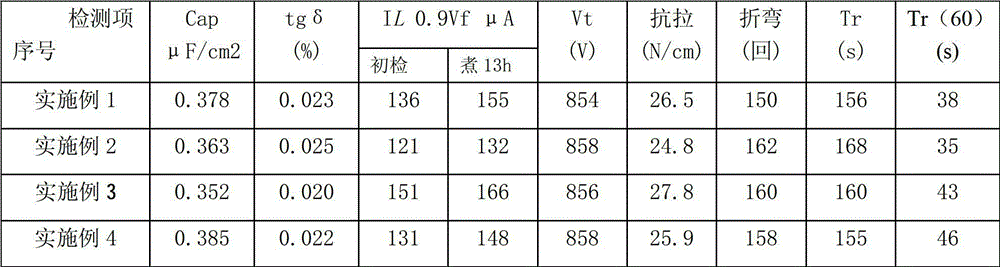

Examples

Embodiment 1

[0022] The corrosion method of ultra-high voltage anode foil for aluminum electrolytic capacitor of the present invention includes the following steps:

[0023] 1. Pretreatment:

[0024] The aluminum foil is immersed in a hydrochloric acid solution with a concentration of 2.0 wt% at 70°C for 150 seconds, and then taken out.

[0025] 2. Level 1 DC electrochemical corrosion:

[0026] Put the above pre-treated aluminum foil into a mixture of 3wt% hydrochloric acid, 20wt% sulfuric acid and 0.1wt% phosphoric acid at a temperature of 85°C and a concentration of 3wt% hydrochloric acid, 20wt% sulfuric acid and 0.1wt% phosphoric acid for direct current electrochemical corrosion. The current density is 0.5A / cm 2 , The power is 30C / cm 2 .

[0027] 3. Medium processing 1:

[0028] Put the above-mentioned aluminum foil that has undergone the first-level direct current electrochemical corrosion into a mixed solution of 3.5wt% hydrochloric acid and 0.08wt% oxalic acid at a temperature of 65°C and a cur...

Embodiment 2

[0038] Another embodiment of the ultra-high voltage anode foil corrosion method for aluminum electrolytic capacitors of the present invention includes the following steps:

[0039] 1. Pretreatment:

[0040] The aluminum foil is immersed in a hydrochloric acid solution with a concentration of 3.5 wt% at 65° C. for 120 seconds and taken out.

[0041] 2. Level 1 DC electrochemical corrosion:

[0042] Put the above-mentioned pre-treated aluminum foil into a mixed solution of 5wt% hydrochloric acid, 15wt% sulfuric acid and 0.25wt% phosphoric acid at a temperature of 80℃ and a concentration of 0.25wt% phosphoric acid for direct current electrochemical corrosion. The current density is 0.4A / cm 2 , The power is 30C / cm 2 .

[0043] 3. Medium processing 1:

[0044] Put the above-mentioned aluminum foil that has undergone the first-level direct current electrochemical corrosion into a mixed solution of 2wt% hydrochloric acid and 0.02wt% oxalic acid at a temperature of 70°C and a current density of ...

Embodiment 3

[0054] Another embodiment of the ultra-high voltage anode foil corrosion method for aluminum electrolytic capacitors of the present invention includes the following steps:

[0055] 1. Pretreatment:

[0056] The aluminum foil is soaked in a hydrochloric acid solution with a concentration of 5 wt% at 60° C. for 120 seconds and taken out.

[0057] 2. Level 1 DC electrochemical corrosion:

[0058] Put the above-mentioned pre-treated aluminum foil into a mixture of 7.5wt% hydrochloric acid, 35wt% sulfuric acid and 0.35wt% phosphoric acid at a temperature of 75°C and a concentration of 7.5wt% for DC electrochemical corrosion. The current density is 0.35A / cm 2 , The power is 25C / cm 2 .

[0059] 3. Medium processing 1:

[0060] Put the above-mentioned aluminum foil that has undergone the first-level DC electrochemical corrosion into a mixed solution of 2wt% hydrochloric acid and 0.14wt% oxalic acid at a temperature of 78°C and a current density of 0.075A / cm 2 , The power is 5C / cm 2 .

[0061] 4. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Electricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com