A dynamic calibration source system with high precision, high linearity and high temperature stability

A dynamic calibration and linear calibration technology, applied in the direction of single semiconductor device testing, etc., can solve the problem that cannot meet the high precision, high linearity and high temperature stability of absolute power measurement calibration, and the conventional signal source cannot meet high precision, high linearity and high temperature stability. Temperature stability and other issues to achieve high linear output, ensure consistency, and high power accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

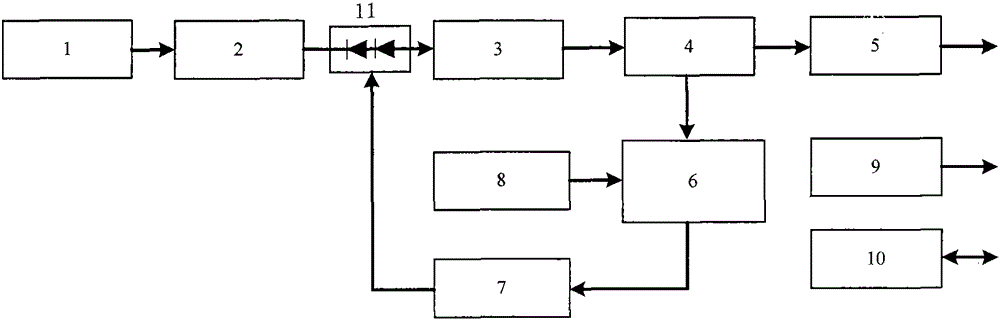

[0016] The dynamic calibration source with high precision, high linearity and high temperature stability described in the present invention includes hardware circuit part and software compensation two parts, such as figure 1 As shown, the specific structure of the hardware circuit part is as follows:

[0017] High-stability voltage-controlled oscillator 1, which generates a 1GHz signal and sends it to the first-stage power amplifier 2 to achieve 14dB first-stage power amplification,

[0018] The model of the first-stage power amplifier 2 can be RF2045, and its output end is connected to the input end of the modulator 11 to realize the feedback control of the amplitude, and the modulator 11 includes two stages of HSMP-3892PIN diodes connected in series,

[0019] The output end of the modulator 11 is connected to the input end of the secondary power amplifier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com