A drainage type segment for tunnel lining

A segment and lining technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of increasing the construction cost of segment lining, potential safety hazards of segment lining, and high groundwater pressure, so as to avoid fine particles blocking holes and blocking Rod phenomenon, protection of tunnel appearance, and effect of reducing water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

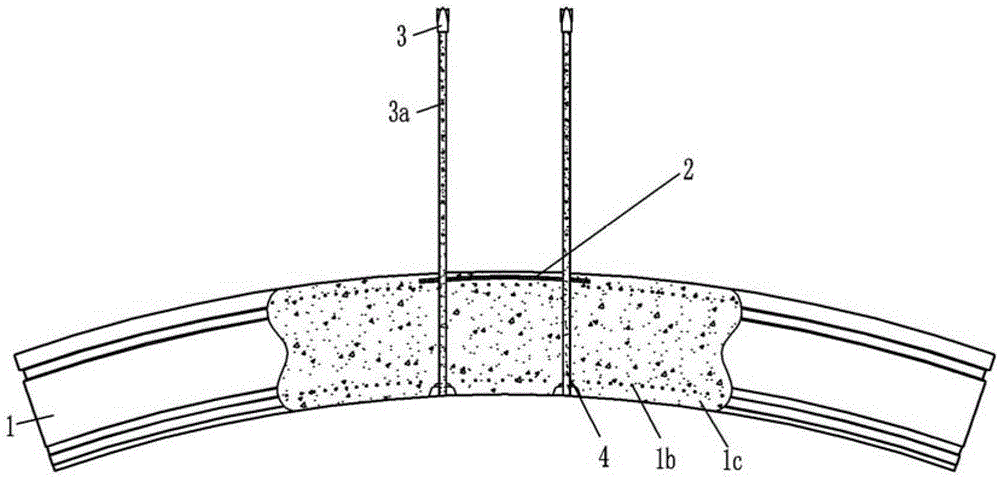

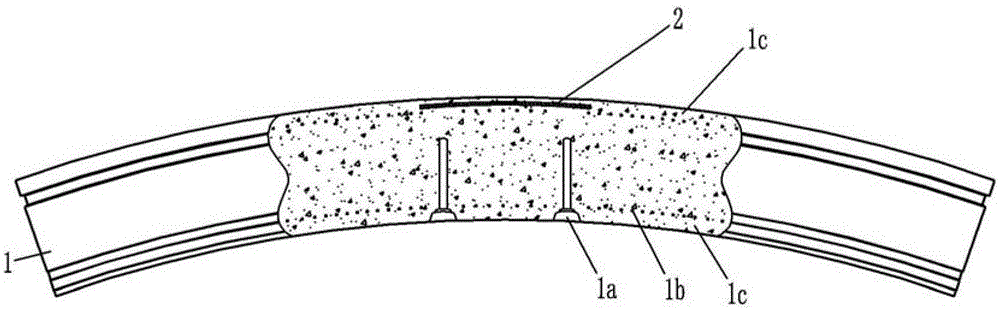

[0021] Figure 1-3 It is shown that the specific embodiment of the present invention is a drainage type segment for tunnel lining, including a reinforced concrete segment 1, a grouting hole or a hoisting hole 1a in the segment 1, a stressed steel bar 1b, and an outer layer Concrete cover 1c. In the concrete protection layer 1c facing one or two grouting holes 1a of the segment 1, the waterproof glue block 2 that can expand in water is pre-embedded; The grouting hole or hoisting hole 1a is inserted, passes through the water-stopping rubber block 2, drills out the concrete protective layer 1c, and has a drainage hole 3a on the rod wall at the outer end of the self-advancing hollow anchor rod 3, and plugs it in its inner cavity. Filter column 4 for filter sand.

[0022] The length of the self-advancing hollow anchor rod 3 protruding from the concrete protection layer 1c in this example is 2-3m; the thickness of the glue block 2 is 2-3cm.

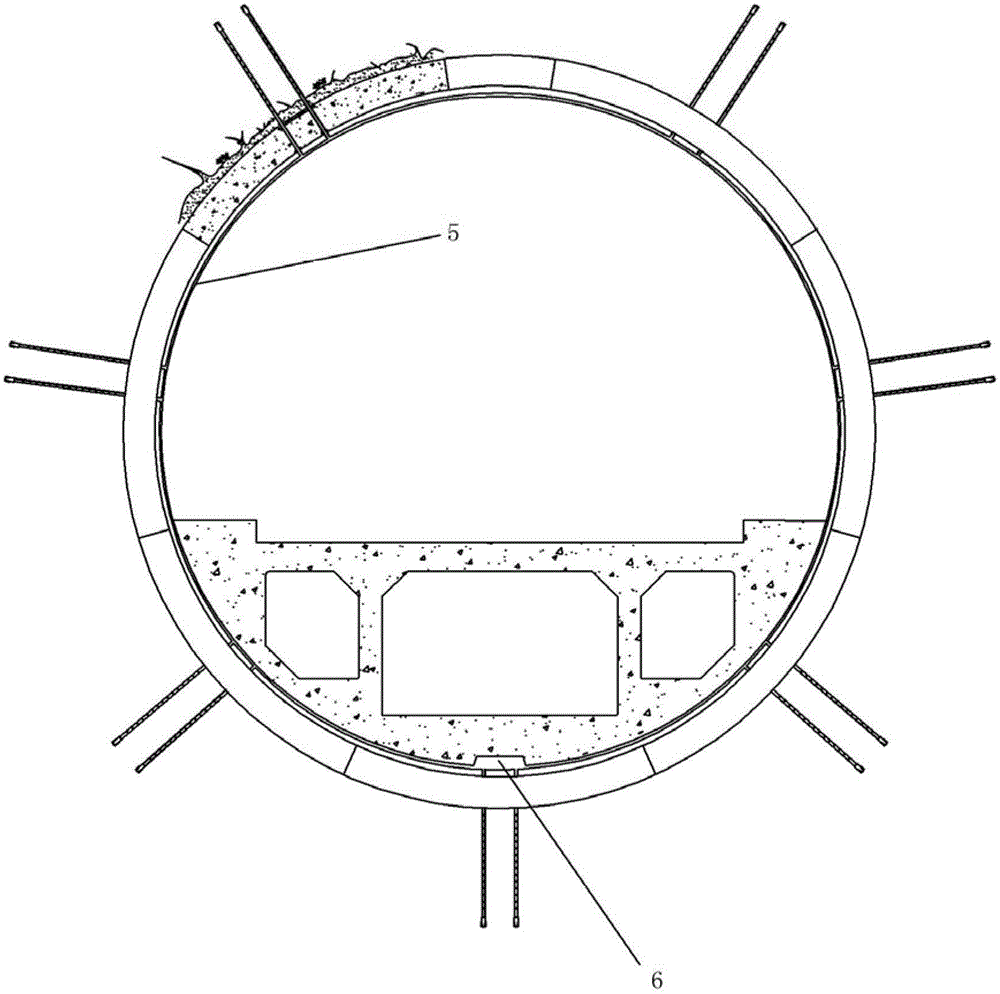

[0023] image 3 Shown, the usage met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com