Plastic deformation method for cast magnesium-gadolinium-yttrium-neodymium-zirconium (Mg-Gd-Y-Nd-Zr) rare earth magnesium-alloy component

A technology of plastic deformation and rare earth magnesium is applied in the field of plastic deformation of as-cast Mg-Gd-Y-Nd-Zr rare earth magnesium alloy components, which can solve the problems of difficult deformation of rare earth magnesium alloy, high use cost, easy cracking and the like. Achieve the effect of saving energy, improving product performance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Taking cast Mg-9Gd-4Y-1Nd-0.4Zr (magnesium-9 gadolinium-4 yttrium-1 neodymium-0.4 zirconium) rare earth magnesium alloy components as an example,

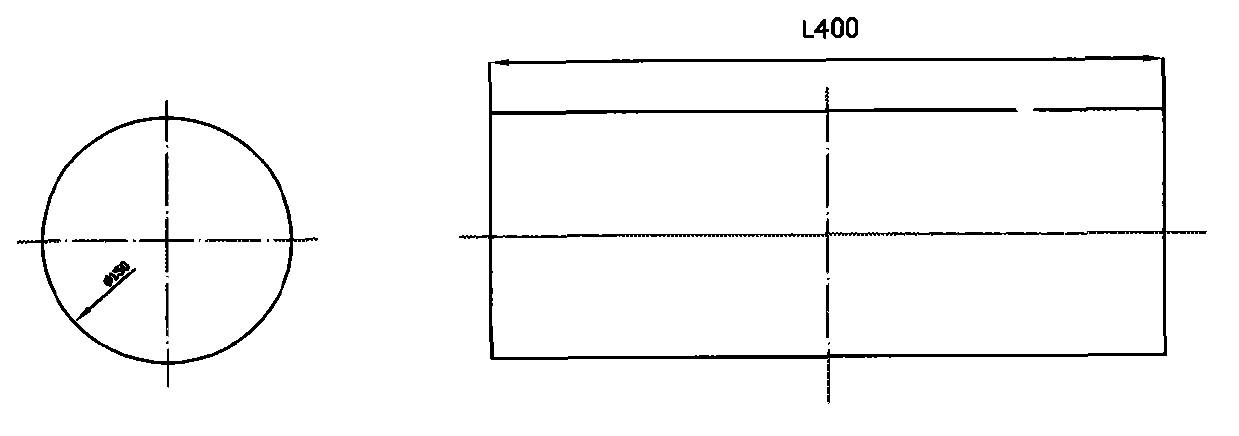

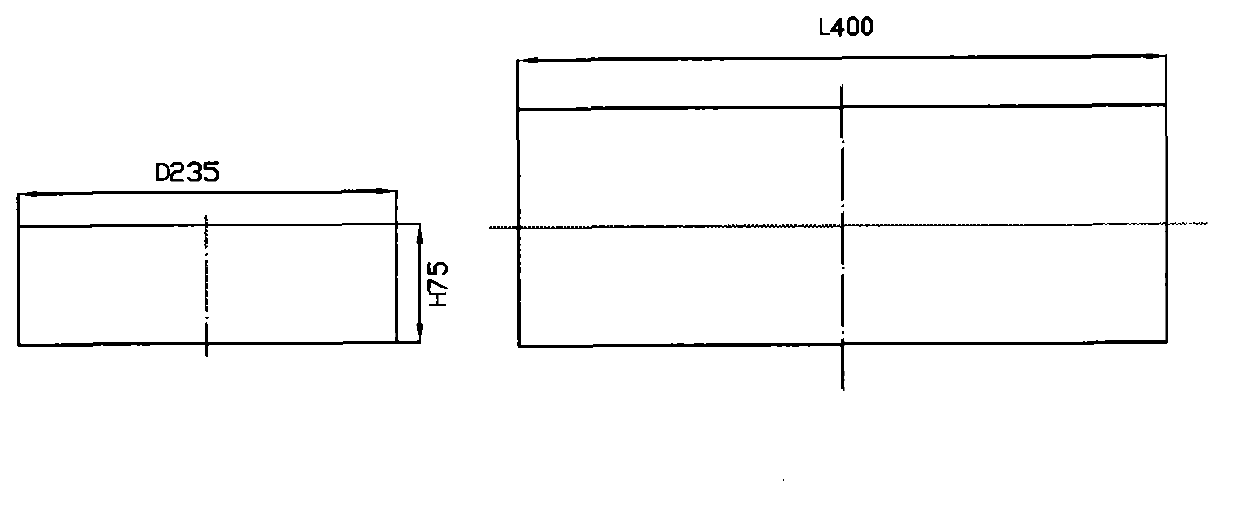

[0030] (1) Magnesium alloy casting rod blanking: according to the volume of the formed component blank, the heat-resistant cast Mg-9Gd-4Y-1Nd-0.4Zr magnesium alloy is sawed and blanked, and the volume of the blank blank is the volume of the formed component hot forging ;The surface is turned into a cast rod with a diameter of φ60mm~φ500mm, such as Figure 3-1 Shown: the diameter of cast rod is φ150mm;

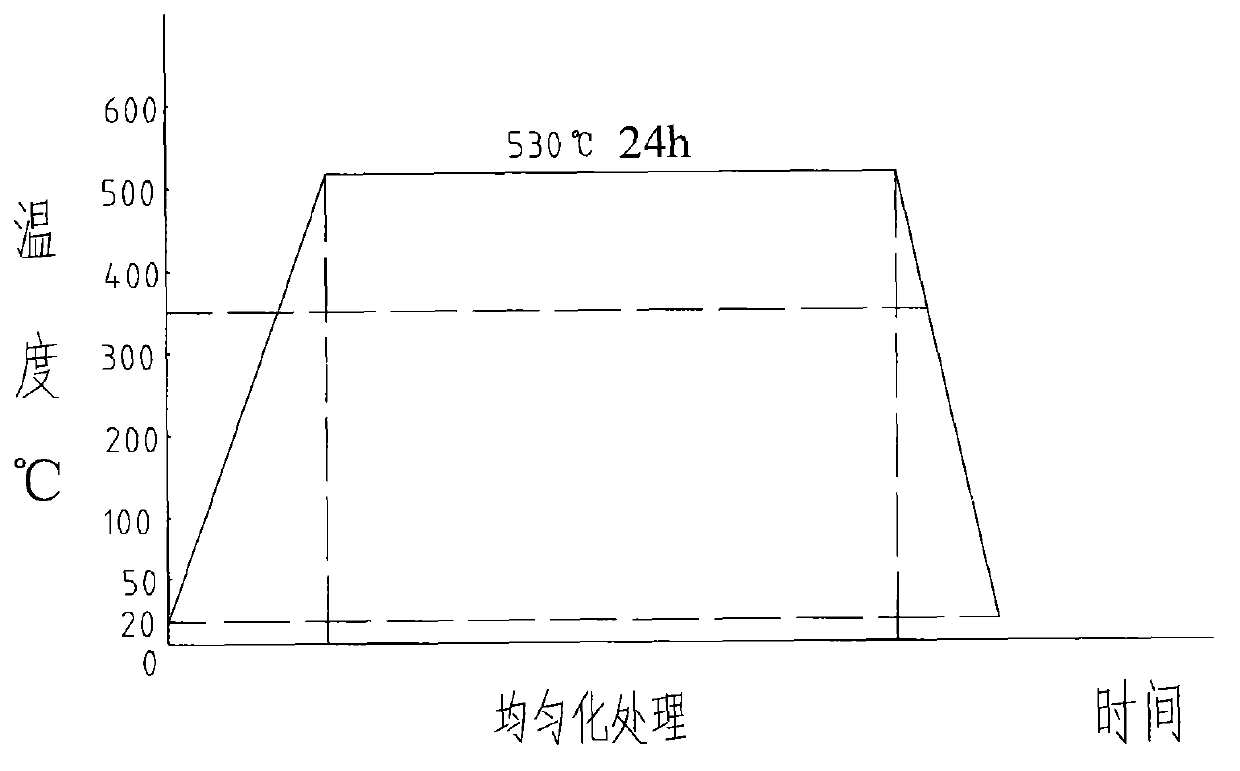

[0031] (2) Homogenization treatment of as-cast structure: heating and heat-insulating the as-cast Mg-9Gd-4Y-1Nd-0.4Zr magnesium alloy billet in a medium-temperature hot air circulation furnace at a temperature of 530±5°C for 24 hours Homogenization treatment is carried out to eliminate the severe dendrite segregation and eutectic structure in the as-cast Mg-9Gd-4Y-1Nd-0.4Zr rare earth magnesium alloy structure, and improve t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com