Variable-temperature circular treatment method of ultrafine C250 maraging steel grains

A maraging steel and variable temperature cycle technology, applied in the field of metal heat treatment, can solve the problems of limited grain refinement effect of solid solution treatment, affecting material application and unsatisfactory effect, etc., achieving small grain size and improving strength and toughness. , the use of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Example 1 of the present invention: a variable temperature cycle treatment method for superfine C250 maraging steel grains, heating C250 maraging steel to 750°C, keeping it warm for 5 minutes, and then water-cooling and quenching to room temperature to achieve the first Secondary cycle treatment: heat the material that has undergone the first cycle treatment to 930°C and keep it warm for 5 minutes, then water-cool and quench to room temperature to realize the second cycle treatment; through the above two variable temperature cycle treatments, C250 Martens grain refinement and homogenization of bulk aging steel.

Embodiment 2

[0009] Example 2 of the present invention: a variable temperature cycle treatment method for superfine C250 maraging steel grains, heating C250 maraging steel to 700°C, keeping it warm for 10 minutes, and then water cooling and quenching to room temperature to achieve the first Secondary cycle treatment: heat the material that has undergone the first cycle treatment to 960°C, keep it warm for 1 minute, and then water-cool and quench it to room temperature to realize the second cycle treatment; through the above two variable temperature cycle treatments, C250 Martens grain refinement and homogenization of bulk aging steel.

Embodiment 3

[0010] Example 3 of the present invention: a variable temperature cycle treatment method for superfine C250 maraging steel grains, heating C250 maraging steel to 780°C, keeping it warm for 1 minute, and then water cooling and quenching to room temperature to achieve the first Secondary cycle treatment: heat the material that has undergone the first cycle treatment to 900°C and keep it warm for 10 minutes, then water-cool and quench to room temperature to realize the second cycle treatment; through the above two variable temperature cycle treatments, C250 Martens grain refinement and homogenization of bulk aging steel.

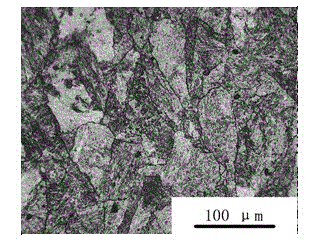

[0011] In order to further verify the experimental effect of the present invention, the metallographic structure of the C250 maraging steel processed by the present invention is compared with the C250 maraging steel of the traditional deformation treatment, and the C250 maraging steel processed by the present invention is The metallographic structure of aging s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com