Method for fermenting butanol and co-producing dietary fiber by corn bran

A technology of dietary fiber and butanol fermentation, which is applied in the direction of fermentation, can solve the problems of high cost, achieve low cost, realize waste utilization, and increase the added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

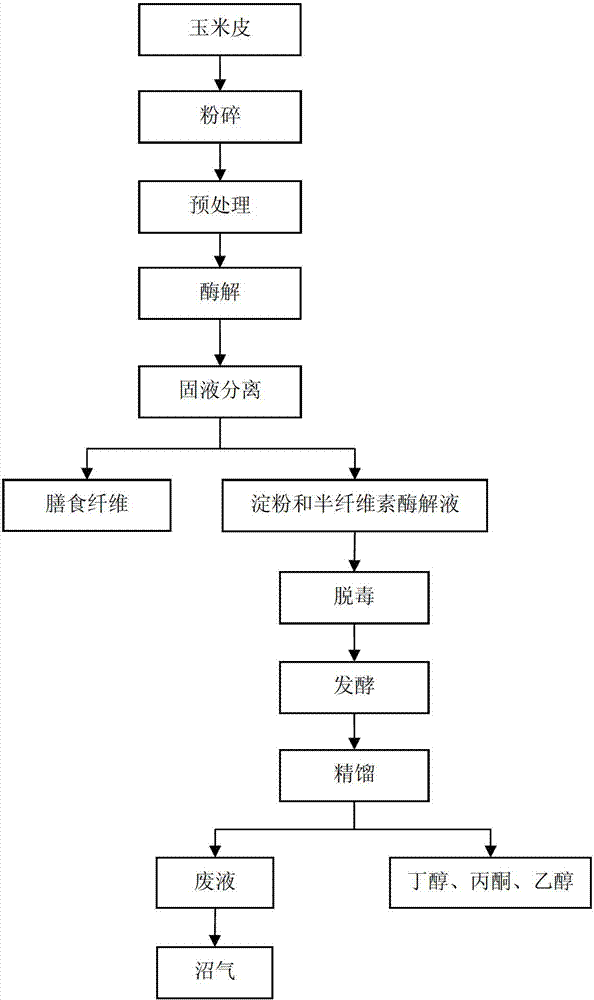

Method used

Image

Examples

Embodiment 1

[0036] Weigh 5 g of corn bran that has been pulverized by ultra-fine airflow to a particle size of 200 mesh, add 50 mL of 0.5% (w / w) sulfuric acid solution (the solid-liquid ratio of corn bran flour to dilute sulfuric acid is 1:10), and react at 140 ° C for 20 min , adjust the pH value of the hydrolyzate to 4.8, add 200 IU / g substrate of glucoamylase, 1.0 IU / g substrate of xylanase, enzymatically hydrolyze at 50°C for 48h, and the speed of the shaker is 150r / min. Filtrate the enzymatic solution, the solid residue is dietary fiber, the dry weight is 1.75g, the swelling property is 1.83g / mL, and the water holding capacity is 195.7%; take the enzymatic solution and add 1% (w / v) activated carbon to detoxify at 50°C for 1 hour After filtering off the activated carbon, add 0.5% (w / v) corn steep liquor powder to the supernatant, inoculate NCIMB8052 strain, and incubate anaerobically at 37°C for 48h. The components of the fermentation product were analyzed by gas chromatography: butan...

Embodiment 2

[0038] Weigh 5g of corn bran that has been pulverized by ultra-fine airflow to a particle size of 100 mesh, add 40mL of 1% (w / w) sulfuric acid solution, and react at 150°C for 20min (the solid-liquid ratio of corn bran flour to dilute sulfuric acid is 1:8) , adjust the pH value of the hydrolyzate to 5.0, add 250 IU / g substrate of glucoamylase, 0.8 IU / g substrate of xylanase, enzymatically hydrolyze at 50°C for 48 hours, and the speed of the shaker is 150r / min. Filtrate the enzymolysis solution, the solid residue is dietary fiber, the dry weight is 1.86g, the swelling property is 1.71g / mL, and the water holding capacity is 191.5%; take the enzymolysis solution and add 2% (w / v) activated carbon After 0.5h of poisoning, filter out the activated carbon, add 0.3% (w / v) ammonium sulfate to the supernatant, inoculate NCIMB8052 strain, and incubate anaerobically at 37°C for 48h. Gas chromatography analysis product composition is: butanol 8.64g / L, total solvent 10.38g / L.

Embodiment 3

[0040]Weigh 5 g of corn bran that has been generally crushed to a particle size of 10 mesh, add 60 mL of 1.5% (w / w) sulfuric acid solution, and react at 120 ° C for 30 minutes (the solid-liquid ratio of corn bran flour to dilute sulfuric acid is 1:12), adjust The pH value of the hydrolyzate was 4.8, 300 IU / g substrate of glucoamylase and 1.0 IU / g substrate of xylanase were added, enzymolysis was carried out at 50°C for 48 hours, and the rotation speed of the shaker was 150r / min. Filtrate the enzymolysis solution, the solid residue is dietary fiber, the dry weight is 1.91g, the swelling property is 1.55g / mL, and the water holding capacity is 182.6%; take the enzymolysis solution and add 0.5% (w / v) activated carbon After poisoning for 1 hour, filter out the activated carbon, add 0.3% (w / v) corn steep liquor to the supernatant, inoculate NCIMB8052 strain, and incubate anaerobically at 37°C for 48 hours. The product components were analyzed by gas chromatography of the fermentatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| swelling | aaaaa | aaaaa |

| swelling | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com