Degradation resistance fire retardation type rigid polyurethane foam material and preparation method thereof

A technology of rigid polyurethane and foam materials, applied in the field of material chemistry, can solve the problems of difficulty in foaming, increase in viscosity of foaming system, etc., and achieve the effects of good dimensional stability, overcoming aging resistance, and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

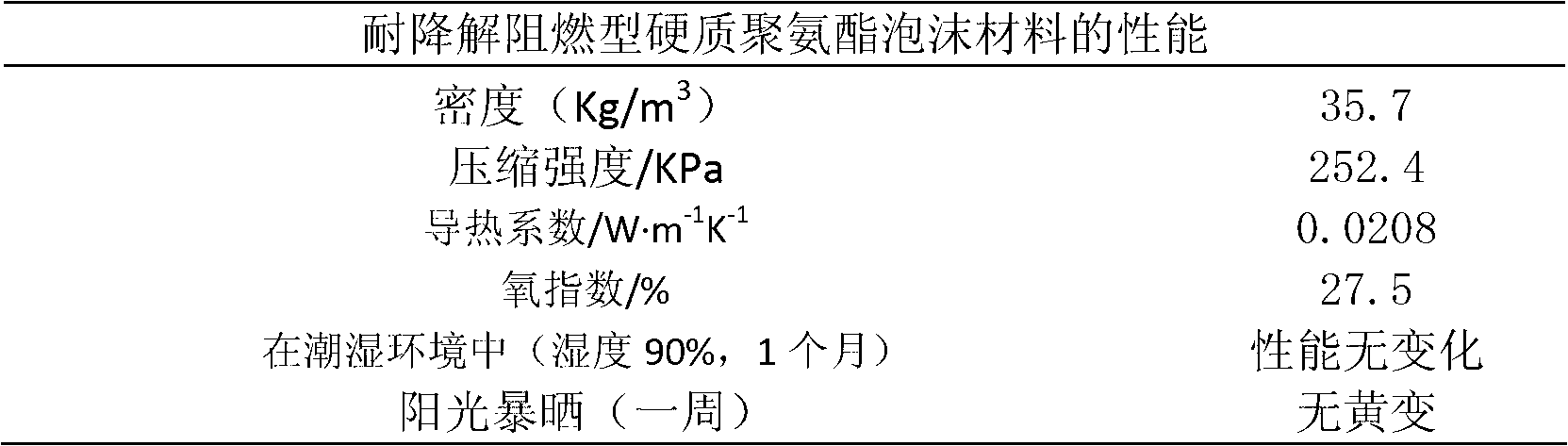

Image

Examples

Embodiment 1

[0030]Component A: Accurately weigh 100 parts of polyphenyl polymethylene polyisocyanate PAPI, brand PM-200, the mass fraction of NCO is 30.1-32.0%, the viscosity (25°C) is 150-250mPa·s, and the average functionality is 2.6~2.7 (Yantai Wanhua Polyurethane Co., Ltd.).

[0031] Preparation of component B: at a temperature of 25°C, accurately weigh 0.5 parts of blowing agent H 2 O, 5.0 parts of crosslinking agent TMP, 1.0 parts of chain extender BDO, 3.0 parts of foam stabilizer B8450, 5.0 parts of A-33, 0.5 part of T-12, composite stabilizer (2.0 parts of a-methylstyrene, 1.0 part UV-234 and 1.5 parts of B11) were added to 70 parts of polyether polyol YD-4114 and 30 parts of polyester polyol PS-3152 accurately weighed in advance, and stirred by a stirrer for 180s at a speed of 200r / min. Among them, polyether polyol YD-4114 has a molecular weight of 545, a hydroxyl value of 470±15mgKOH / g, and a viscosity (25°C) of 1500mPa·s (Hebei Yadong Company); polyester polyol PS-3152 has a ...

Embodiment 2

[0038] Component A: Accurately weigh 100 parts of polyphenyl polymethylene polyisocyanate PAPI, brand PM-200, the mass fraction of NCO is 30.1-32.0%, the viscosity (25°C) is 150-250mPa·s, and the average functionality is 2.6~2.7 (Yantai Wanhua Polyurethane Co., Ltd.).

[0039] Preparation of component B: at a temperature of 25°C, accurately weigh 0.5 parts of blowing agent H 2 O, 3.0 parts of crosslinking agent TMP, 2.0 parts of chain extender BDO, 3.0 parts of foam stabilizer B8450, 5.0 parts of A-33, 0.5 part of T-12, composite stabilizer (2.0 parts of a-methylstyrene, 1.0 part UV-234 and 1.5 parts of B11) were added to 70 parts of polyether polyol YD-4114 and 30 parts of polyester polyol PS-3152 accurately weighed in advance, and stirred by a stirrer for 180s at a speed of 200r / min. Among them, polyether polyol YD-4114 has a molecular weight of 545, a hydroxyl value of 470±15mgKOH / g, and a viscosity (25°C) of 1500mPa·s (Hebei Yadong Company); polyester polyol PS-3152 has a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com