Environment-friendly and simple preparation method for synthesizing isophorone from acetone

A technology of isophorone and acetone, which is applied in the field of environmentally friendly and simple preparation of isophorone from acetone, can solve the problems of restricting the development of isophorone industrialization, unfavorable environmental protection, and low conversion rate of acetone, and meet the needs of market products Quality requirements, conducive to industrialization and automation, and the effect of generating scale that is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

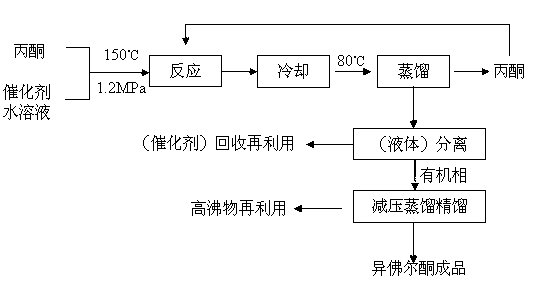

Image

Examples

Embodiment 1

[0021] Put 1000Kg of acetone as raw material, 100Kg of NaOH aqueous solution containing 3 Kg of catalyst, 0.2 Kg of auxiliary catalyst magnesium oxide, aluminum oxide, calcium oxide, barium oxide, and lanthanum rare metal element into the autoclave, heat to 130°C, and rotate at 250 rpm. The reaction was continuously stirred at constant temperature for 2 hours, then cooled to 80°C, and the unreacted acetone was distilled and cooled to reflux for next use. After the root of the kettle is static, the liquid is separated, and the catalyst aqueous solution is released for use next time, and the remaining product is distilled under reduced pressure to obtain the finished product by distilling the isophorone.

[0022] The product composition after reaction is:

[0023] Acetone 756Kg

[0024] Diacetone Alcohol 40Kg

[0025] Mesityl oxide 105Kg

[0026] Isophorone 142Kg

[0027] Water 45Kg

[0028] Other high boiling substances 12Kg

[0029] Using such a preparation method, the c...

Embodiment 2

[0031] Put 1000Kg of raw material acetone, 100Kg of NaOH aqueous solution containing 3 Kg of catalyst, 0.2 Kg of auxiliary catalyst magnesium oxide, aluminum oxide, calcium oxide, barium oxide and lanthanum rare metal element into the autoclave, heat to 150°C, and rotate at 250 rpm. The reaction was continuously stirred at constant temperature for 2 hours, then cooled to 80°C, and the unreacted acetone was distilled and cooled to reflux for next use. After the root of the kettle is static, the liquid is separated, and the catalyst aqueous solution is released for use next time, and the remaining product is distilled under reduced pressure to obtain the finished product by distilling the isophorone.

[0032] The product composition after reaction is:

[0033] Acetone 447Kg

[0034] Diacetone Alcohol 31Kg

[0035] Mesityl oxide 56Kg

[0036] Isophorone 355Kg

[0037] Water 97Kg

[0038] Other high boiling substances 14Kg

[0039] Using such a preparation method, the conver...

Embodiment 3

[0041] Put 1000Kg of acetone as the raw material, 100Kg of NaOH aqueous solution containing 3 Kg of catalyst, 0.2 Kg of auxiliary catalyst magnesium oxide, aluminum oxide, calcium oxide, barium oxide and lanthanum rare metal element into the autoclave, heat to 200°C, and rotate at 250 rpm. The reaction was continuously stirred at constant temperature for 2 hours, then cooled to 80°C, and the unreacted acetone was distilled and cooled to reflux for next use. After the root of the kettle is static, the liquid is separated, and the catalyst aqueous solution is released for use next time, and the remaining product is distilled under reduced pressure to obtain the finished product by distilling the isophorone.

[0042] The product composition after reaction is:

[0043] Acetone 430Kg

[0044] Diacetone Alcohol 15Kg

[0045] Mesityl oxide 54Kg

[0046] Isophorone 280Kg

[0047] Water 125Kg

[0048] Other high boiling substances 96Kg

[0049] Using such a preparation method, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com