Energy-saving dry powder type building mortar

A technology of mortar and dry powder, which is applied in the field of building materials, can solve the problems of difficult control of measurement accuracy, inability to meet different requirements, and large differences in shrinkage functions, etc., and achieve the effects of convenient civilized construction, excellent mechanical properties, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is implemented according to the following method: at normal temperature, various solid raw materials are stacked according to classification, automatically weighed by the electronic weighing system according to the predetermined weight parts, and then physically mixed, and the materials are concentrated and fed to the pulverizer to be crushed into fine particles , Stir evenly to get the product, which is transported to the construction site in the form of bag or bulk, and can be used directly after adding water and mixing.

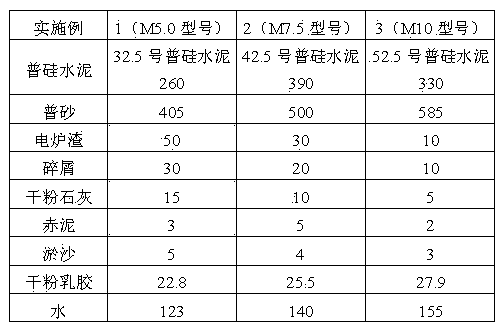

[0020] In Example 1 to Example 3, mortars of models M5.0~10 were respectively prepared, and different models can be selected according to building requirements during construction. The parts by weight of the raw materials used in the three embodiments are shown in Table 1, and the unit is Kg.

[0021] Table 1

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com