Method for removing total phosphor by chemical nickel-plating wastewater treatment

A technology for electroless nickel plating and wastewater treatment, which is used in metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

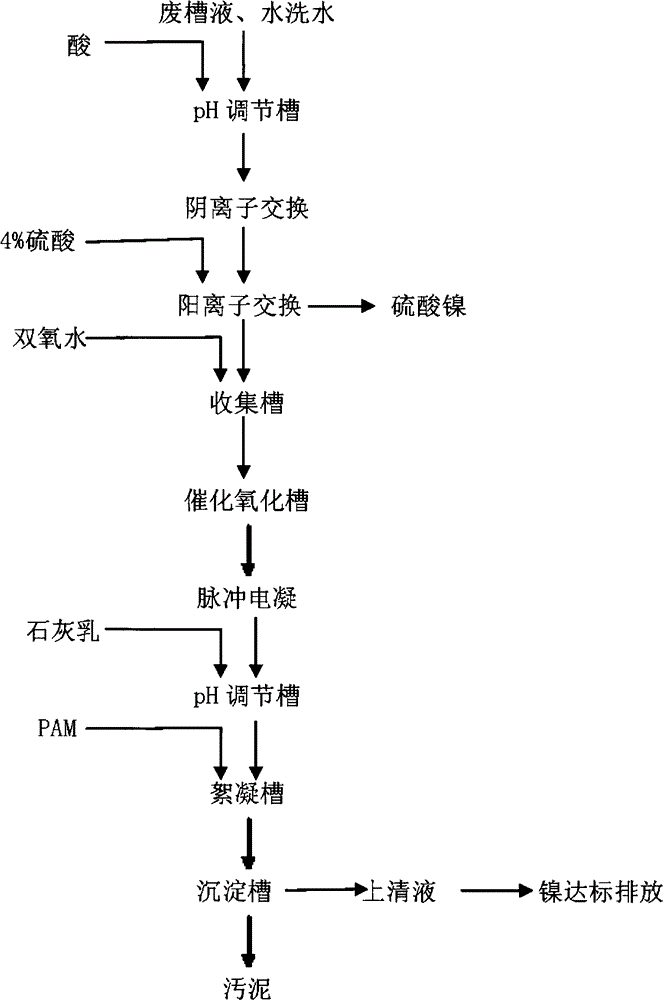

Image

Examples

Embodiment 1

[0050] Embodiment 1: Before the present invention, Kunying Electronics Kunshan Co., Ltd. treated electroless nickel-plating waste water with Fenton's reagent, and the daily treatment capacity was 90m 3 . Because it is an early factory, the nickel detection port of the environmental impact assessment is the total waste water discharge port instead of the current workshop discharge standard, and its total waste water discharge is 6000m 3 / day, that is, the dilution capacity of the total discharge port is >60 times.

[0051] The water pollution analysis of the waste nickel solution before treatment is as follows:

[0052] pH

Cu

Ni

mn

Ag

COD

NH 3 -N

NO 3 -N

TP

4.65

1.037

2136.5

11.1

0.2

34164

2181

1949

23063

[0053] Washing water pollution analysis is as follows:

[0054] Project (PPM)

pH

Ni

Cu

COD

P

N-NH 3

TN

4~5

<100

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com