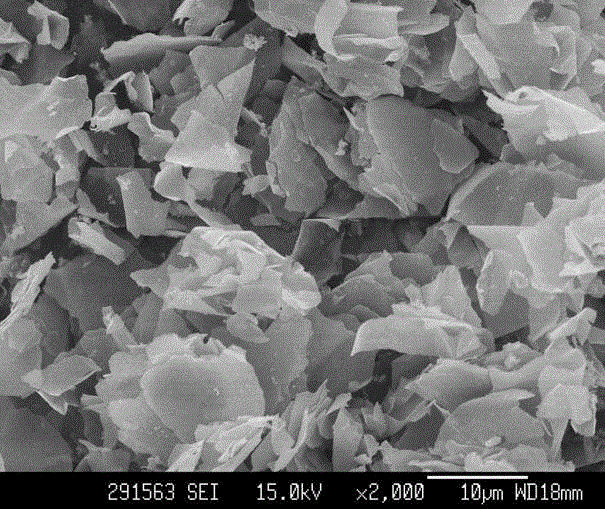

Method for preparing nanometer flake silver powder through chemical deposition

A technology of chemical deposition and flaky silver powder, which is applied in the field of preparation of nano-thick flaky silver powder, can solve the problems of uncontrollable, many influencing factors, rough surface, etc., and achieve uniform thickness of powder flakes, precise control of thickness, and smooth surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The acrylic resin BR106 with a molecular weight of 40000 was dissolved in the cyclohexanone solution so that the content of the acrylic resin was 15wt%. Then, the resin solution was uniformly coated on the PET substrate by screen printing, baked in an oven at 80 °C for 1 h, and then taken out to obtain a smooth, even and uniform soluble resin layer.

[0031] Hydrophilic and sensitization treatments are carried out before the chemical deposition of the silver film. The PET substrate coated with heat-shrinkable acrylic resin was immersed in a 0.35 mM sodium dodecyl sulfate solution, taken out after 10 min, and rinsed with ultrapure water to make the soluble resin layer hydrophilic. Then the substrate after hydrophilic treatment was immersed in 17.7 mM stannous chloride solution for sensitization, took it out after 10 min, and rinsed with ultrapure water.

[0032] A silver film with nanoscale thickness is deposited on the substrate surface by chemical deposition method. ...

Embodiment 2

[0038] The acrylic resin BR116 with a molecular weight of 60000 was dissolved in a methyl ethyl ketone solution, so that the acrylic resin content was 10 wt %; then the resin solution was evenly coated on the glass substrate by screen printing, and baked in an oven at 80 °C for 1 Take it out after h to obtain a flat, smooth and uniform soluble resin layer.

[0039] The glass substrate coated with the soluble resin layer is successively subjected to hydrophilic and sensitization treatments. Hydrophilic treatment involves immersing the substrate coated with a soluble resin layer into a 0.35 mM sodium dodecyl sulfate solution, taking it out after 5 min, and then rinsing it with ultrapure water. The sensitization treatment is to immerse the hydrophilic treated substrate in a 17.7 mM stannous chloride solution, take it out after 5 min, and then rinse it with ultrapure water.

[0040]Finally, a silver film with a nanoscale thickness is deposited on the surface of the substrate by c...

Embodiment 3

[0047] The acrylic resin BR116 with a molecular weight of 60,000 was dissolved in ethyl acetate, so that the acrylic resin content was 12 wt %; then the resin solution was evenly coated on the stainless steel substrate by screen printing, and baked in an oven at 120 °C Take it out after 1 min to obtain a flat, smooth and uniform soluble resin layer.

[0048] Hydrophilic and sensitized treatment of stainless steel substrate coated with soluble resin. Hydrophilic treatment is to immerse the substrate coated with soluble resin in 0.35 mM sodium dodecyl sulfate solution, take it out after 7 min, and rinse it with ultrapure water. Sensitization treatment is to immerse the substrate in a 17.7 mM stannous chloride solution after hydrophilic treatment, take it out after 7 min, and finally rinse it with ultrapure water.

[0049] A silver film with nanoscale thickness is deposited on the substrate surface after hydrophilic and sensitization treatment by chemical deposition method. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com