Hydrophobic silica gel composite resin-based VOC adsorbent

A composite resin and adsorbent technology, applied in the field of environmental chemistry, can solve the problems of poor thermal stability, inability to effectively increase the adsorption capacity of low-concentration organic waste gas, and inability to apply stably for a long time, and achieve increased specific surface area and high selective adsorption. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

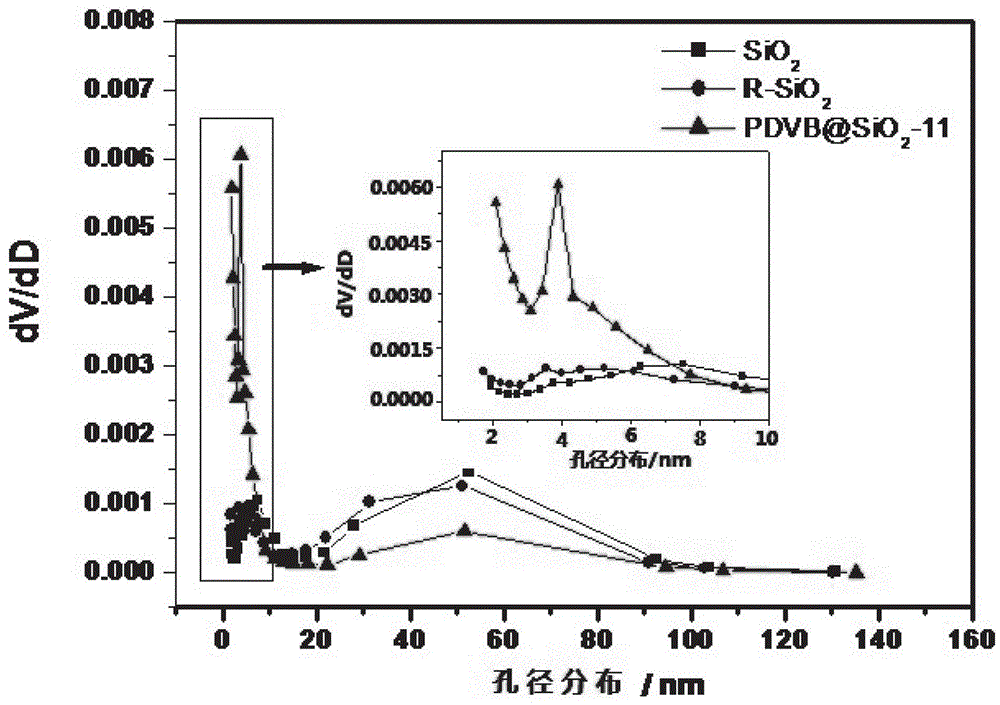

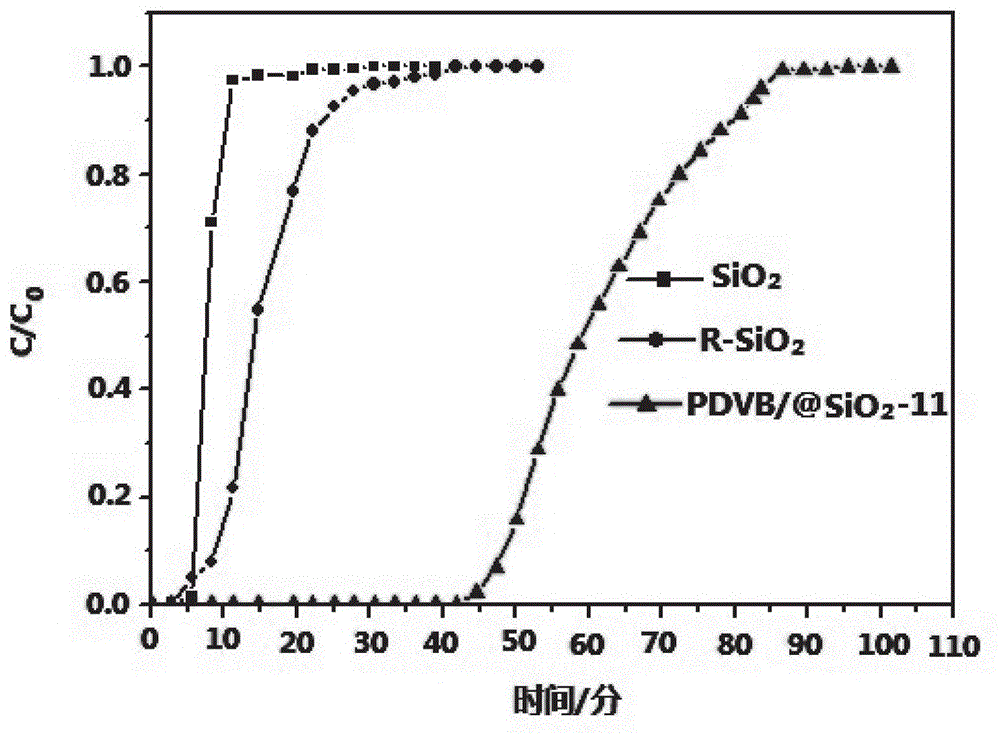

[0026] Take 5 g macroporous silica gel (the specific surface area is 119m 2 / g, pore size 20-50 nm) was washed twice with 100ml deionized water, dried at 110°C for 10 h to obtain purified silica gel; put the purified silica gel into a flask, add 200ml toluene, 30ml γ-( Methacryloyloxy)propyltrimethoxysilane, mixed and stirred in a water bath at 90 °C under the protection of nitrogen for 15 h, filtered with suction, and washed the silica gel with 100 ml of ethanol until it was white, and then dried at 110 °C for 2 h to obtain Silane-modified silica gel; take 1.6 ml of p-divinylbenzene monomer (DVB), 0.02 g of azobisisobutyrocyanide dissolved in 3.2 ml of tetrahydrofuran, stir and mix in an ice-water bath as a resin polymerization solution, and slowly add the polymerization solution dropwise Add to silane-modified silica gel, stir while adding dropwise to form wet silica gel; transfer the wet silica gel to a crystallization kettle, crystallize at 120 °C for 24 hours in a closed ...

Embodiment 2

[0033] Dissolve 3.2 ml of p-divinylbenzene monomer (DVB) and 0.02 g of azobisisobutylcyanide in 1.6 ml of tetrahydrofuran, stir and mix in an ice-water bath to form a resin polymerization solution, and the rest of the steps are the same as in Example 1. Obtained sample PDVBSiO 2 -12. Nitrogen adsorption BET test found that the specific surface area is 32 m 2 / g, the pore size is in the range of 10-30 nm, toluene (1000mg / m 3 ) adsorption capacity is only 18 mg / g. Compared with macroporous silica, PDVBSiO 2 Although -12 has strong hydrophobicity, the specific surface area has dropped significantly, indicating that excessive p-divinylbenzene polymerization modification will cause blockage of the original silica gel pores, and the polymerization of PDVB in the particle gap will cause the adsorption capacity of the sample to toluene dramatically drop.

Embodiment 3

[0035] Dissolve 2.4 ml of p-divinylbenzene monomer (DVB) and 0.02 g of azobisisobutylcyanide in 2.4 ml of tetrahydrofuran, stir and mix in an ice-water bath to form a resin polymerization solution, and the rest of the steps are the same as in Example 1. Obtained sample PDVBSiO 2 -13. Nitrogen adsorption BET test found that the specific surface area is 54 m 2 / g, the pore size is in the range of 10-20 nm, toluene (1000mg / m 3 ) adsorption capacity is only 24 mg / g. Compared with macroporous silica, PDVBSiO 2 -13 has strong hydrophobicity, but the specific surface area also drops significantly, which makes the adsorption capacity of the sample to toluene drop significantly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com