Mesoporous graphite type carbon nitride/nitrogen doped graphene sol nanocomposite and method for preparing same

A graphitic carbon nitride, nanocomposite material technology, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve problems such as no public reports, and achieve a wide range of applications, low cost and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, mpg-C 3 N 4 The preparation method of N-graphene sol nanocomposite material is to be finished by following steps:

[0028] (1) Add 40 mg of graphene oxide and 20 mg of sodium dodecylbenzenesulfonate (the mass ratio of graphene oxide to surfactant is 2:1) into 3 mL of deionized water, and mix well by ultrasonication for 30 minutes to obtain a colloidal solution . Wherein, the mass ratio of graphene oxide and surfactant is 2:1, and the concentration of colloidal solution is 20g / L;

[0029] (2) Add 40mg mpg-C to the colloidal solution 3 N 4 , among them, graphene oxide and mpg-C 3 N 4 The mass ratio of graphene oxide to nitrogen-containing compound ammonia water is 1:45, and then add 1.8g of ammonia water, (the concentration of ammonia water is 25%) (the mass ratio of graphene oxide to nitrogen-containing compound ammonia water is 1:45) to the mixed solution. Cover and stir evenly at 25°C for 30 minutes.

[0030] (3) Transfer the mixture into a ...

Embodiment 2

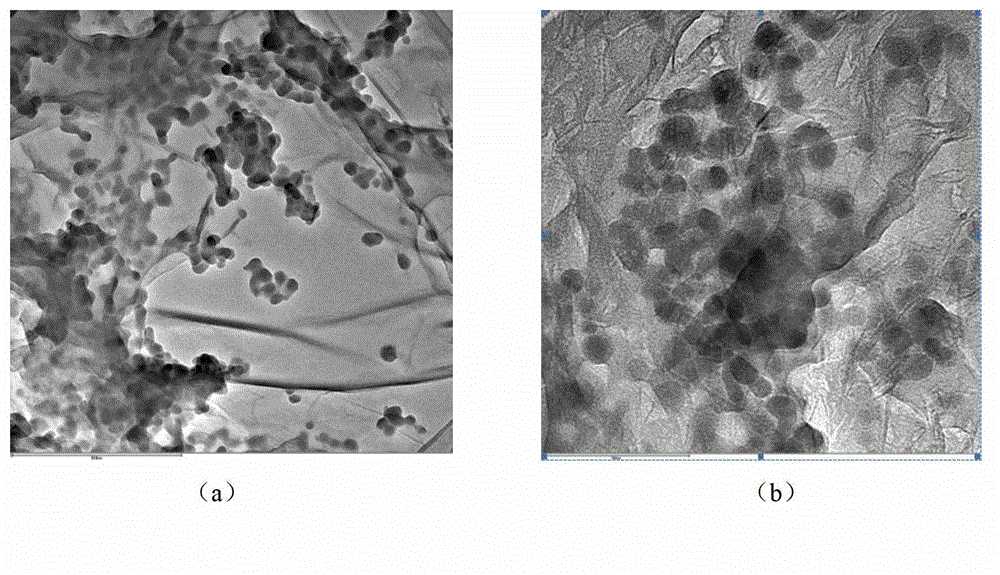

[0034]The present embodiment is different from embodiment 1 in that: the surfactant used is sodium dodecylsulfonate. Other steps and parameters are the same as in Example 1. In the mesoporous graphite-type carbon nitride / nitrogen-doped graphene sol nanocomposite material prepared in this embodiment, the number of layers of nitrogen-doped graphene is 3-5 layers, and the layer thickness is 1.3nm; The pore size of carbon nitride is 10-15nm, and the specific surface area is 80-300m 2 / g, distributed uniformly and disorderly on the surface of nitrogen-doped graphene.

Embodiment 3

[0036] The difference between this example and Example 1 is that the masses of graphene oxide and sodium dodecylbenzenesulfonate used are 50 mg and 10 mg respectively, and the mass ratio of the two is 5:1. Other steps and parameters are the same as in Example 1. In the mesoporous graphite-type carbon nitride / nitrogen-doped graphene sol nanocomposite material prepared in this embodiment, the number of layers of nitrogen-doped graphene is 4-6 layers, and the layer thickness is 1.4nm; The pore size of carbon nitride is 10-15nm, and the specific surface area is 80-300m 2 / g, distributed uniformly and disorderly on the surface of nitrogen-doped graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com