Novel absorbent for capturing and separating carbon dioxide

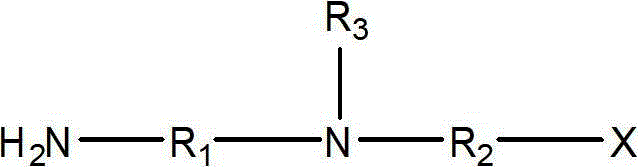

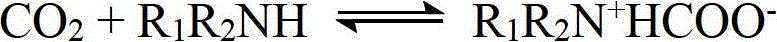

A carbon dioxide and absorbent technology, applied in the direction of absorption, separation, chemical separation, etc., can solve the problems of equipment corrosion and desorption energy consumption, low absorption capacity, slow absorption rate, etc., to achieve desorption and high gas purification , the effect of fast absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

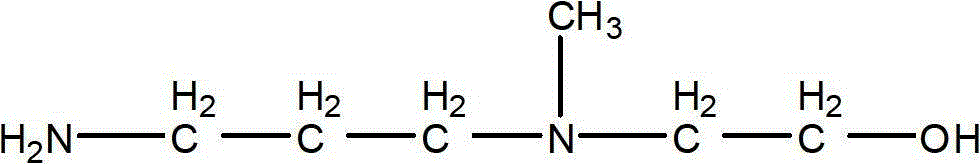

[0031] Embodiment 1: respectively 5%, 20%, 30%, 40%, 50%, 60%, 70% and 80% N-methyl-N-(2-hydroxyethyl)-1 by weight percentage, 3-Propylenediamine aqueous solution absorbs CO 2 , the absorption temperature is 10-60°C, and the pressure is normal pressure.

Embodiment 2

[0032] Embodiment 2: Contain 5%, 20%, 30%, 40%, 50%, 60%, 70% and 80% N-methyl-N-(2-hydroxyethyl)-1,3 by weight percentage -Propylenediamine aqueous solution absorbs CO 2 , the absorption temperature is 10-60°C, and the pressure is 0.1-6MPa.

Embodiment 3

[0033] Embodiment 3: Contain 30% N-methyl-N-(2-hydroxyethyl)-1,3-propanediamine by weight percentage, 60% water, 0-10% MEA is made into aqueous solution to absorb CO 2 , the absorption temperature is 10-60°C, and the pressure is 0.1-6MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com