Double pH adjustment flue gas desulphurization system and control method thereof

A desulfurization system and control method technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve difficulties, increase liquid-gas ratio and other problems, achieve fast dissolution, reduce liquid-gas ratio, and enhance desulfurization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

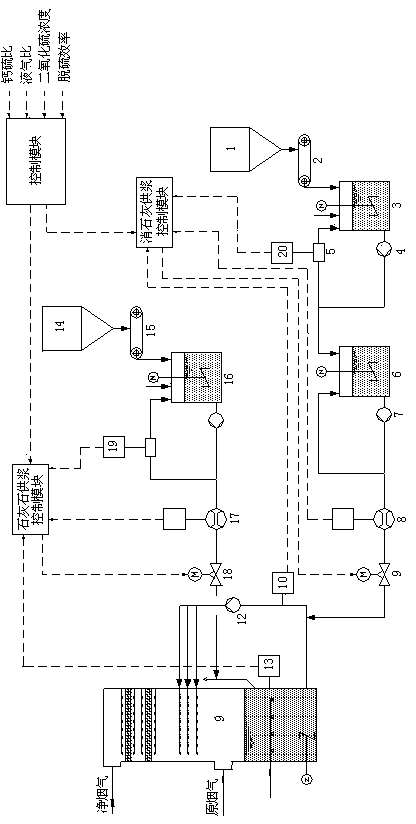

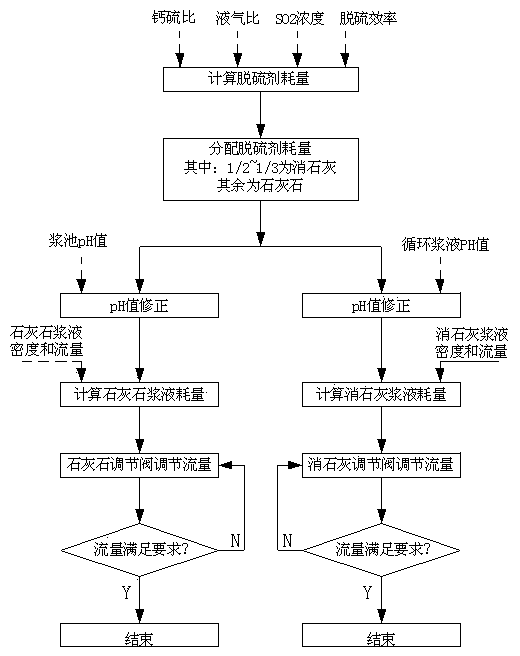

[0023] see figure 1 , the invention includes a desulfurization device, a limestone supply device connected to the desulfurization device, a slaked lime supply device and a control module. The desulfurization device includes an absorption tower 11 and a circulating pump 12 placed on a circulating slurry pipeline. The limestone supply device includes a limestone bin 14, a limestone feeder 15, a limestone slurry tank 16, a limestone flow meter 17 and a limestone regulating valve 18 connected in sequence, and a limestone pH meter 13 is connected to the bottom of the absorption tower 11. The limestone slurry supply control module in the limestone supply device is respectively connected with the water storage tank one 19, the limestone flow meter 17, the limestone regulating valve 18 and the limestone pH meter 13 for control. The hydrated lime supply device includes a quicklime bin 1, a hydrated lime feeder 2, a lime digester 3, a hydrated lime delivery pump 4, a hydrated lime slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com