Fuel cells with integrated cathode and anode bipolar plates

A fuel cell and bipolar plate technology, applied in the direction of fuel cells, fuel cell manufacturing, fuel cell components, etc., can solve the problems of complex structure, low power generation efficiency, large contact internal resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

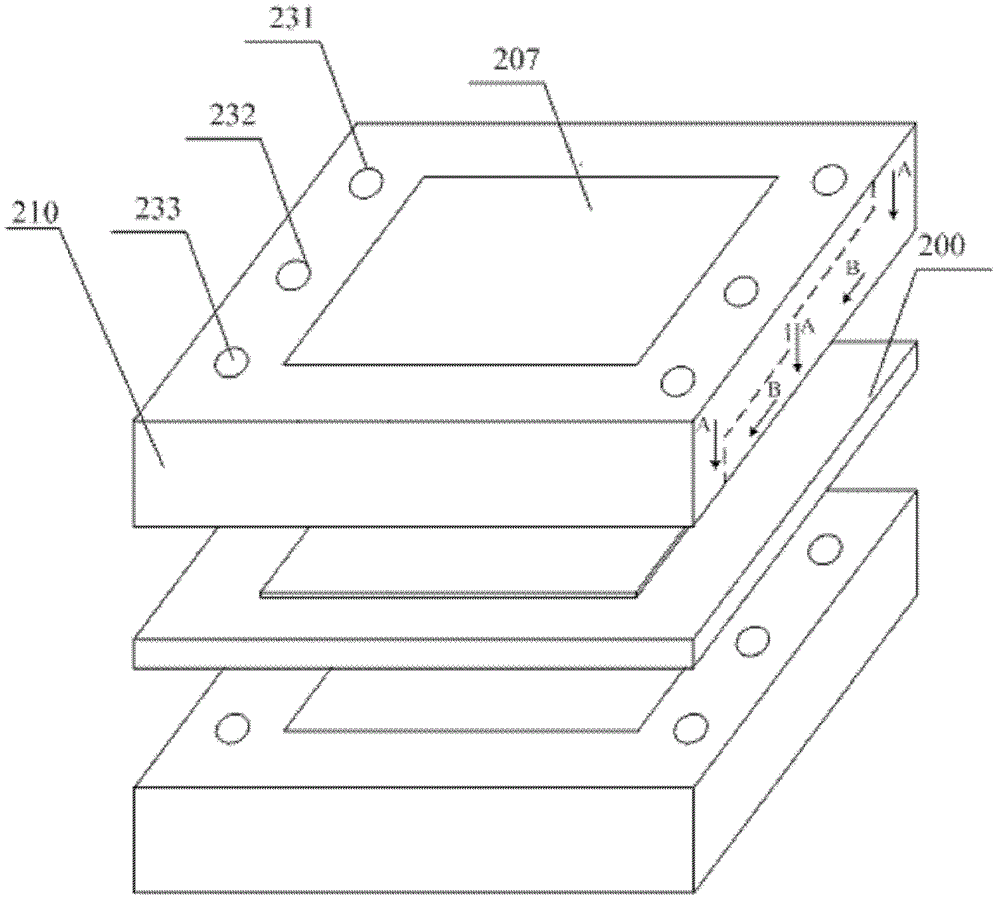

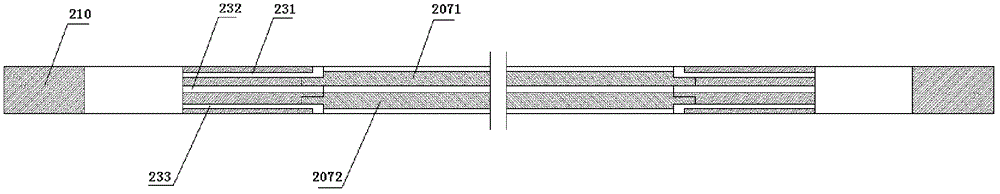

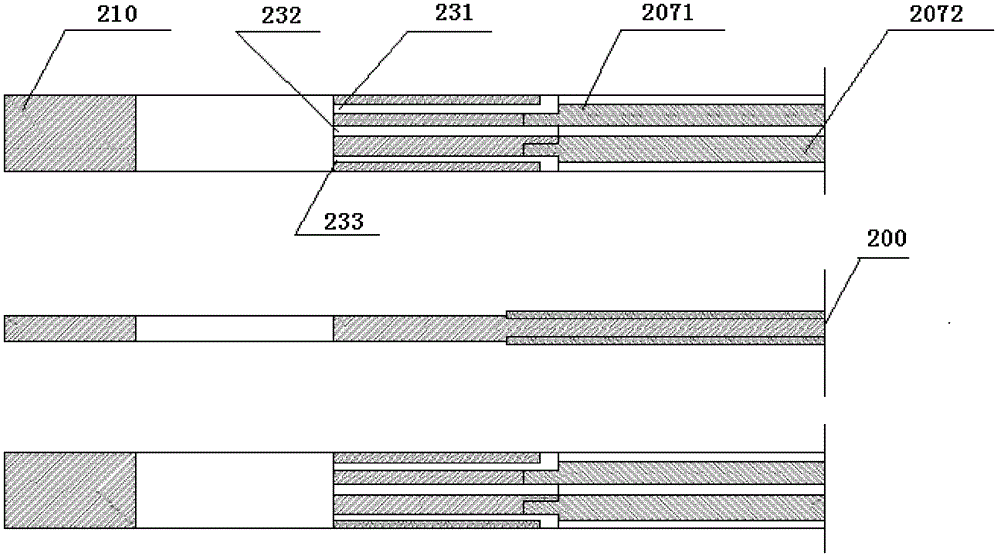

[0013] Such as Figure 1 to Figure 3 As shown, this embodiment provides a fuel cell with an integrated cathode and anode bipolar plates, including alternately arranged bipolar plates and a membrane electrode assembly 200; the bipolar plate includes an electrochemical reaction part and a non-electrochemical reaction part 210; characterized in that: the non-electrochemical reaction part is an integrated frame, and the electrochemical reaction part 210 is nested in the non-electrochemical reaction part frame. In this way, the non-electrochemical reaction part 210 of an anode plate and the non-electrochemical reaction part 210 of a cathode plate in two adjacent battery cells in the prior art are improved into an integral structure, which not only makes the internal structure of the fuel cell more It is compact and helps to simplify the manufacturing process. At the same time, the two-machine board of this one-piece structure can reduce the contact internal resistance between the s...

Embodiment 2

[0020] Such as Figure 1 to Figure 3 As shown, the present invention also provides another embodiment of the fuel cell with integrated cathode and anode bipolar plates, the fuel cell includes alternately arranged bipolar plates and membrane electrode assemblies 200, and the bipolar plates include electric The chemical reaction part and the non-electrochemical reaction part 210, the structure of the non-electrochemical reaction part 210 is consistent with the non-electrochemical reaction part 210 described in the above-mentioned embodiment one, but its electrochemical reaction part is made of conductive material The integrated structure combines the anode electrochemical reaction part 2072 and the cathode electrochemical reaction part 2071 described in the above-mentioned embodiment 1 into one, and simultaneously has the anode electrochemical reaction part 2072 and the cathode electrochemical reaction part 2072 described in the above-mentioned embodiment 1 The function of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com