LiFePO4 precursor hollow sphere and preparation method thereof

A technology of precursors and hollow spheres, which can be used in electrical components, battery electrodes, circuits, etc., and can solve problems such as difficult access to precursors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Weighing of raw materials: Weigh 1.2 g lithium hydroxide, 4.7 g iron phosphate, 1.6 g glucose and 9.6 g oxalic acid respectively, and measure 250 ml deionized water.

[0027] 2. Mixing: Mix the raw materials weighed above with deionized water, heat and stir to dissolve.

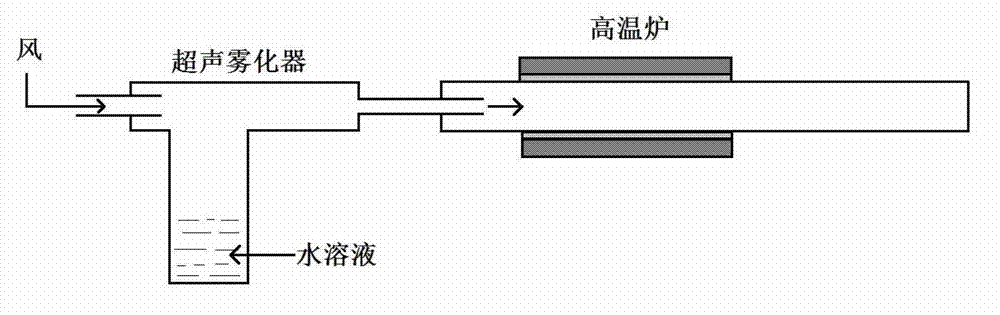

[0028] 3. Atomization: Pour the above solution into an ultrasonic nebulizer, and perform ultrasonic atomization at a frequency of 1.7MHz to form mist.

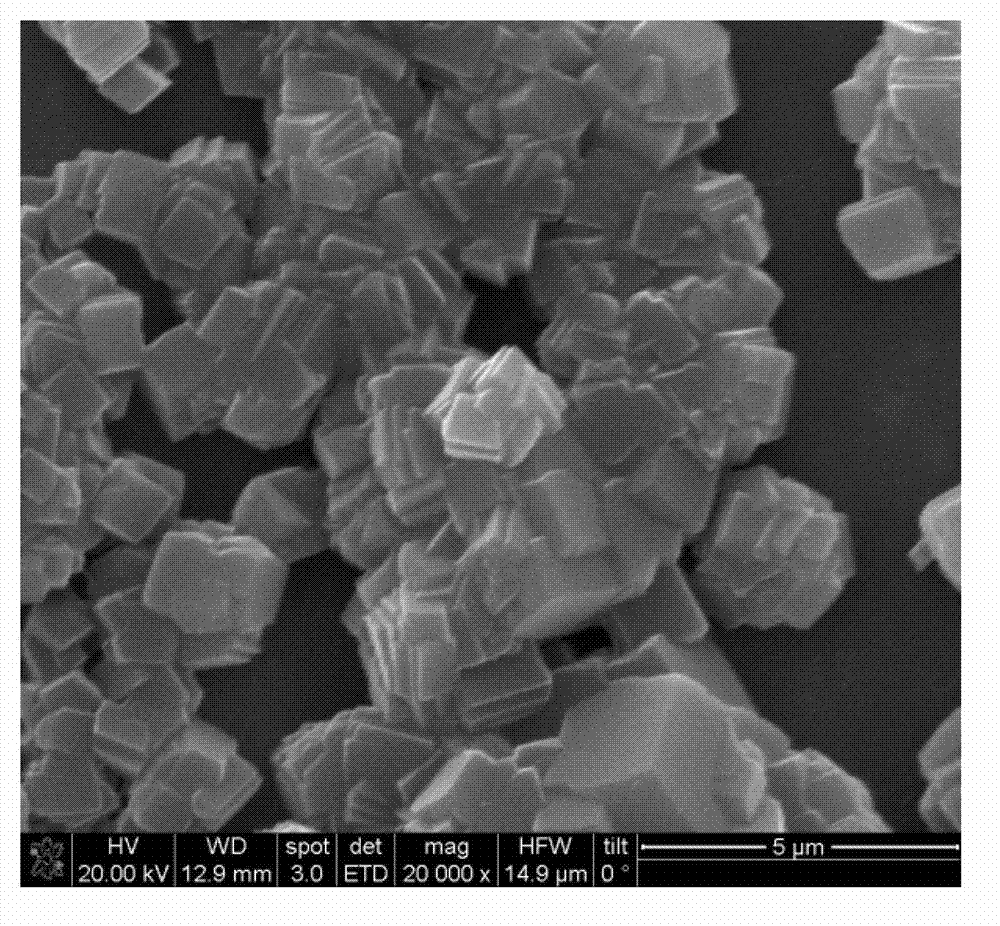

[0029] 4. Drying: The wind blows the droplets through a high-temperature furnace for drying at a drying temperature of 150°C, and collects irregular lumps of LiFePO after drying. 4 Precursor, scanning electron microscope photo as figure 2 shown. The schematic diagram of the device is as figure 1 shown.

Embodiment 2

[0031] 1. Weighing of raw materials: Weigh 1.2 g lithium hydroxide, 4.7 g iron phosphate, 1.6 g glucose and 9.6 g oxalic acid respectively, and measure 250 ml deionized water.

[0032] 2. Mixing: Mix the raw materials weighed above with deionized water, heat and stir to dissolve.

[0033] 3. Atomization: Pour the above solution into an ultrasonic nebulizer, and perform ultrasonic atomization at a frequency of 1.7MHz to form mist.

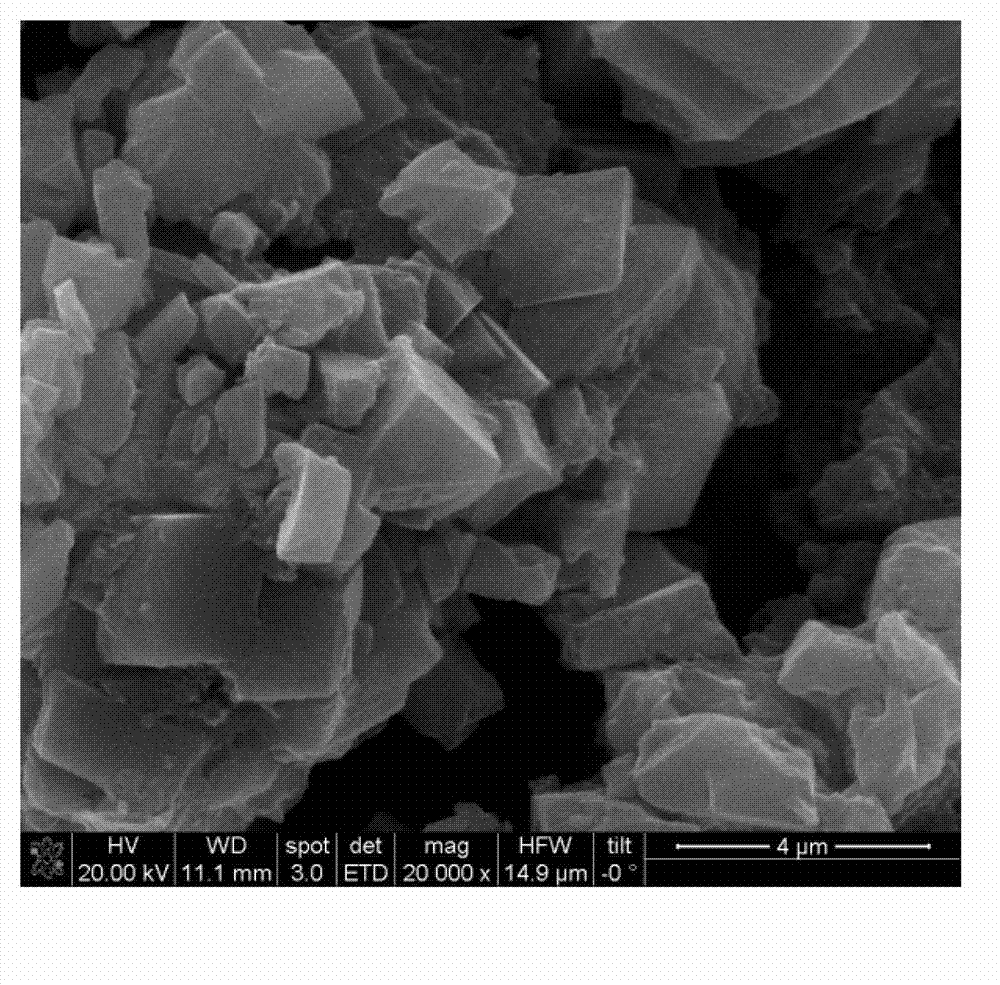

[0034] 4. Drying: The wind blows the droplets through a high-temperature furnace to dry at a temperature of 200°C. After drying, collect irregular lumps of LiFePO 4 Precursor, scanning electron microscope photo as image 3 shown.

Embodiment 3

[0036] 1. Weighing of raw materials: Weigh 1.2 g lithium hydroxide, 4.7 g iron phosphate, 1.6 g glucose and 9.6 g oxalic acid respectively, and measure 250 ml deionized water.

[0037] 2. Mixing: Mix the raw materials weighed above with deionized water, heat and stir to dissolve.

[0038] 3. Atomization: Pour the above solution into an ultrasonic nebulizer, and perform ultrasonic atomization at a frequency of 1.7MHz to form mist.

[0039] 4. Drying: The wind blows the droplets through a high-temperature furnace to dry at a temperature of 250 ° C. After drying, the hollow spherical LiFePO is collected. 4 The precursor, the outer diameter of the hollow sphere is 100nm-5um, and the shell thickness is about 27nm. Scanning electron microscope photos as Figure 4 As shown, the energy dispersive X-ray spectrum as Figure 7 As shown, the transmission electron microscope pictures are shown as Figure 10 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com