Component substrate and manufacture method thereof

A technology for component substrates and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, final product manufacturing, etc., can solve problems such as bending and deformation of flexible substrates, achieve stress relief, good water and oxygen resistance, and increase bending Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

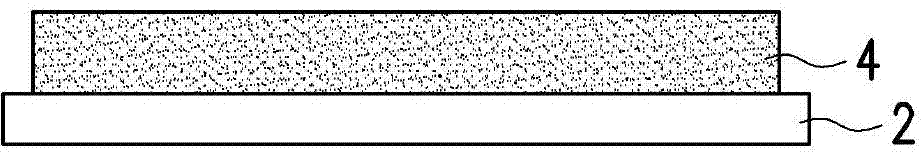

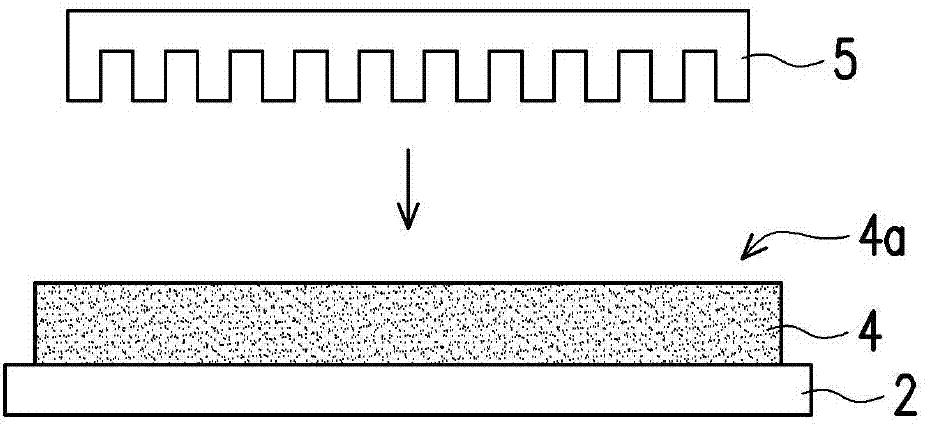

[0050] Figure 1A to Figure 1E It is a schematic diagram of the manufacturing process of the element substrate according to an embodiment of the present invention. Please refer to Figure 1A Firstly, a substrate 4 is formed on a glass substrate 2, wherein the glass substrate 2 may also be other suitable rigid substrates. In this embodiment, the substrate 4 is, for example, a plastic substrate. The substrate 4 is coated by, for example, slot die coating, spin coating, spray coating, and thermal evaporation. In addition, in other embodiments, the substrate 4 may also be a polymer substrate or other suitable flexible substrates.

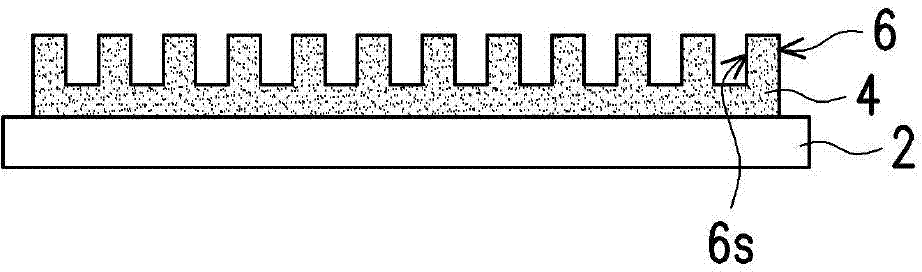

[0051] Next, please refer to Figure 1B as well as Figure 1C , performing a patterning process on the substrate 4 to form a patterned structure 6 on the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com