400Hz structural performance balanced cable for ships and manufacture method thereof

A technology of structural performance and balanced cables, which is applied in the direction of cable/conductor manufacturing, power cables, cables, etc., can solve the problems of not meeting the cable flexibility requirements, unable to reduce the bending radius of the cable, and unable to achieve a small bending radius, etc., to achieve favorable Effects of heat dissipation, cable core structure balance, and mutual interference prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

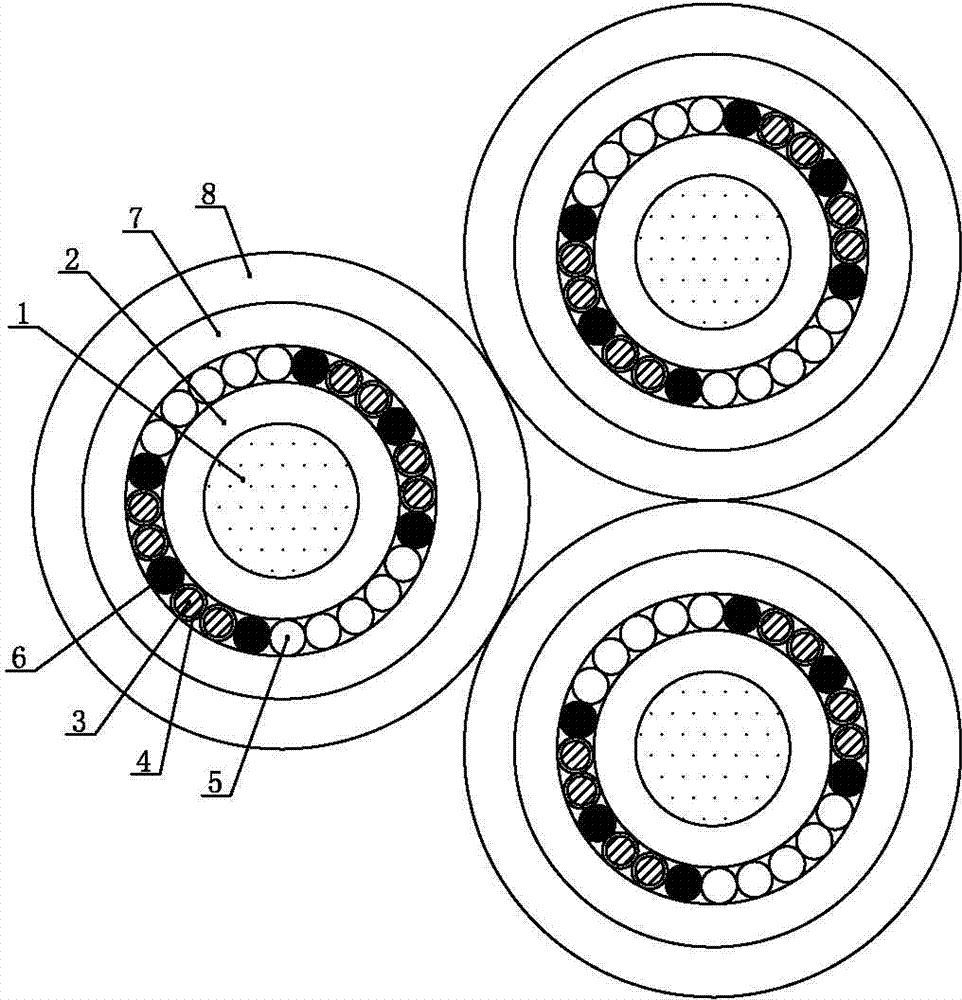

[0022] Such as figure 1 As shown, the manufacturing method of the 400Hz structural performance balanced cable for ships of the present invention includes the following steps in turn: multiple tinned annealed copper wires with a diameter of 0.25 mm are twisted into strands with a pitch ratio of 10 times in the same direction, According to the calculation of the 98% ratio of the outer diameter of the bundle strand, the perfect circular compression mold is used, and each strand is subjected to compression molding treatment and then re-twisted into a power cable conductor. The direction is carried out, and the tinned annealed copper wire adopts the Class 6 type of the IEC 60228 standard; then, the power cable insulation layer is extruded around the outer circumference of the power cable conductor. The insulation layer of the power cable is an ethylene-propylene rubber insulation layer with a dielectric constant not greater than 2.5, and its heat-resistant temperature is 105°C. Th...

Embodiment 2

[0029] Such as figure 1 As shown, the manufacturing method of the 400Hz structural performance balanced cable for ships of the present invention includes the following steps in turn: multiple tinned annealed copper wires with a diameter of 0.28mm are twisted into strands with a pitch ratio of 11 times in the same direction, According to the calculation of the 99% ratio of the outer diameter of the bundle stranding, the perfect circular compression mold is used, and each strand is subjected to compression molding treatment and then re-twisted into a power cable conductor. The direction is carried out, and the tinned annealed copper wire adopts the Class 6 type of the IEC 60228 standard; then, the power cable insulation layer is extruded around the outer circumference of the power cable conductor. The insulation layer of the power cable is an ethylene-propylene rubber insulation layer with a dielectric constant not greater than 2.5, and its heat-resistant temperature is 105°C. ...

Embodiment 3

[0036] Such as figure 1 As shown, the manufacturing method of the 400Hz structural performance balanced cable for ships of the present invention comprises the following steps in turn: multiple tinned annealed copper wires with a diameter of 0.3 mm are twisted into strands with a 12 times pitch diameter ratio in the same direction, According to the calculation of the 99% ratio of the outer diameter of the bundle strand, the perfect circular compression mold is used, and each strand is subjected to compression molding treatment, and then re-twisted into a power cable conductor. The direction is carried out, and the tinned annealed copper wire adopts the Class 6 type of the IEC 60228 standard; then, the power cable insulation layer is extruded around the outer circumference of the power cable conductor. The insulation layer of the power cable is an ethylene-propylene rubber insulation layer with a dielectric constant not greater than 2.5, and its heat-resistant temperature is 105...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com