Thermal wind speed sensor encapsulated based on carbon nanotube array

A carbon nanotube array, carbon nanotube layer technology, applied in the direction of using thermal variables to measure fluid velocity, instruments, measuring devices, etc., can solve problems such as difficulty in avoiding negative effects, inability to achieve final packaging, etc., to achieve good consistency, The effect of good axial heat transfer performance and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be described in detail below in conjunction with the drawings.

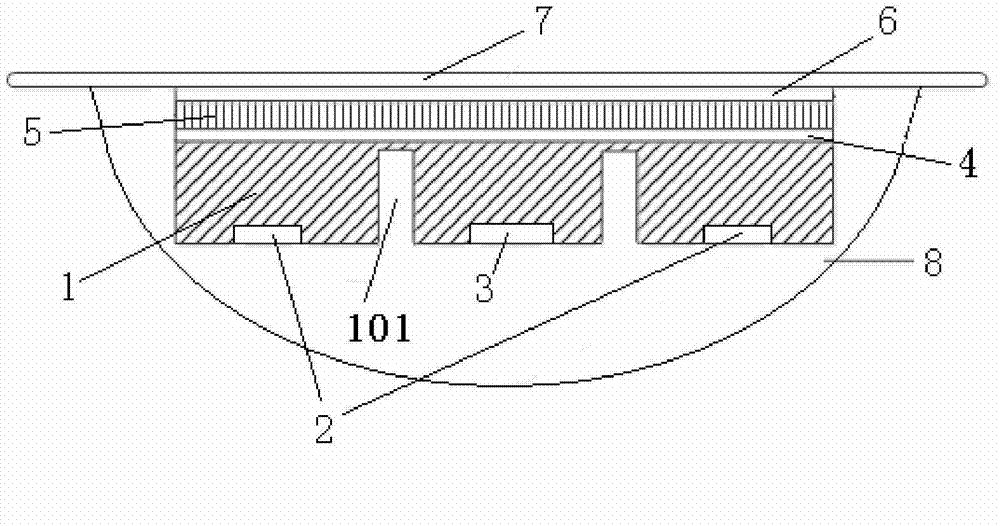

[0014] Such as figure 1 As shown, a thermal wind speed sensor based on carbon nanotube array packaging of the present invention includes a silicon substrate 1, four temperature measuring elements 2, a heating element 3, a copper film layer 4, a carbon nanotube layer 5, and a nickel film layer 6 and heat insulating dielectric layer 8. The top surface of the silicon substrate 1 is connected to the bottom surface of the copper film layer 4, the top surface of the copper film layer 4 is connected to the bottom surface of the carbon nanotube layer 5, and the top surface of the carbon nanotube layer 5 is connected to the bottom surface of the nickel film layer 6. The heating element 3 and the four temperature measuring elements 2 are respectively embedded on the bottom surface of the silicon substrate 1. The four temperature measuring elements 2 are evenly dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com