Combined vibration isolation mounting for subways

A combined, vibration isolation technology, applied in the direction of shock absorber-spring combination, shock absorber, spring, etc., can solve the problem of high cost of floating plate, achieve the effect of good long-term life, low cost and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

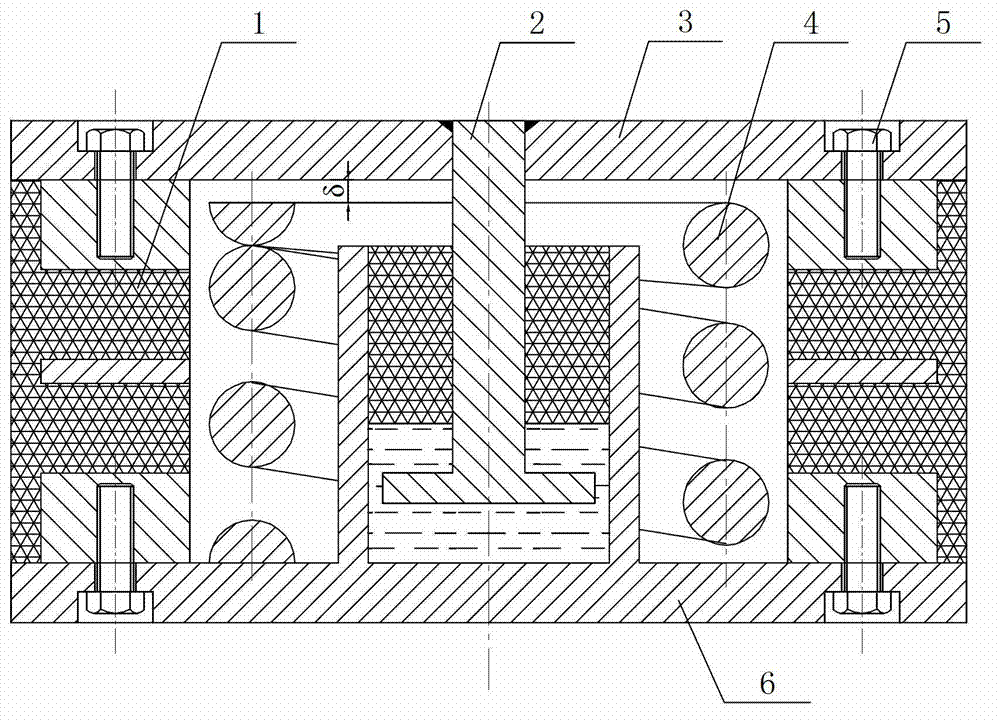

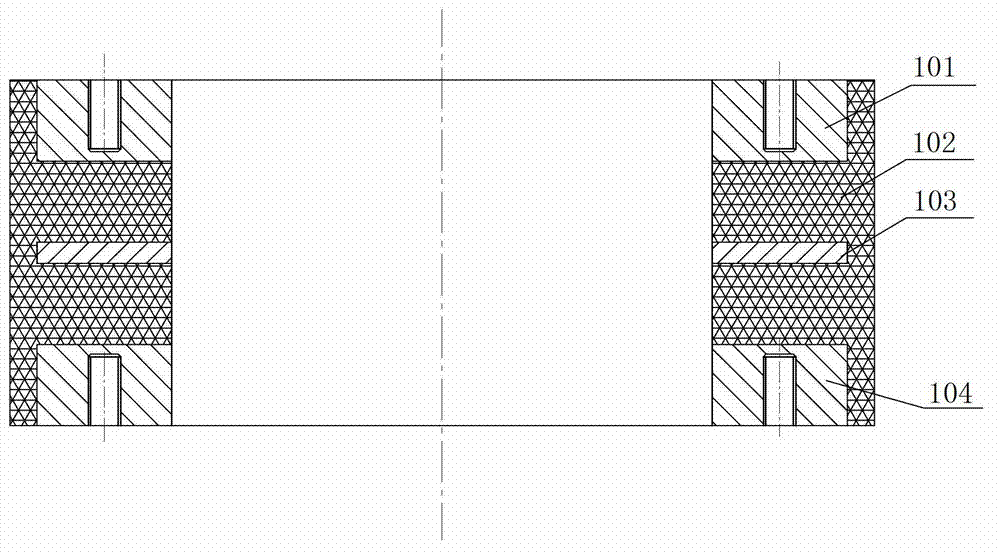

[0036] An embodiment of a combined vibration isolation device for subways of the present invention is as follows Figure 1 to Figure 3As shown, the vibration isolation device includes an upper coupling plate 3 at the top and a lower coupling plate 6 at the lower part, and it is characterized in that the vibration isolation device also includes a vibration isolation mechanism between the upper coupling plate 3 and the lower coupling plate 6, The vibration isolation mechanism is connected with the upper connection plate 3 and the lower connection plate 6 respectively to form an integral structure, and the vibration isolation mechanism can realize the function of isolating the vibration of the subway.

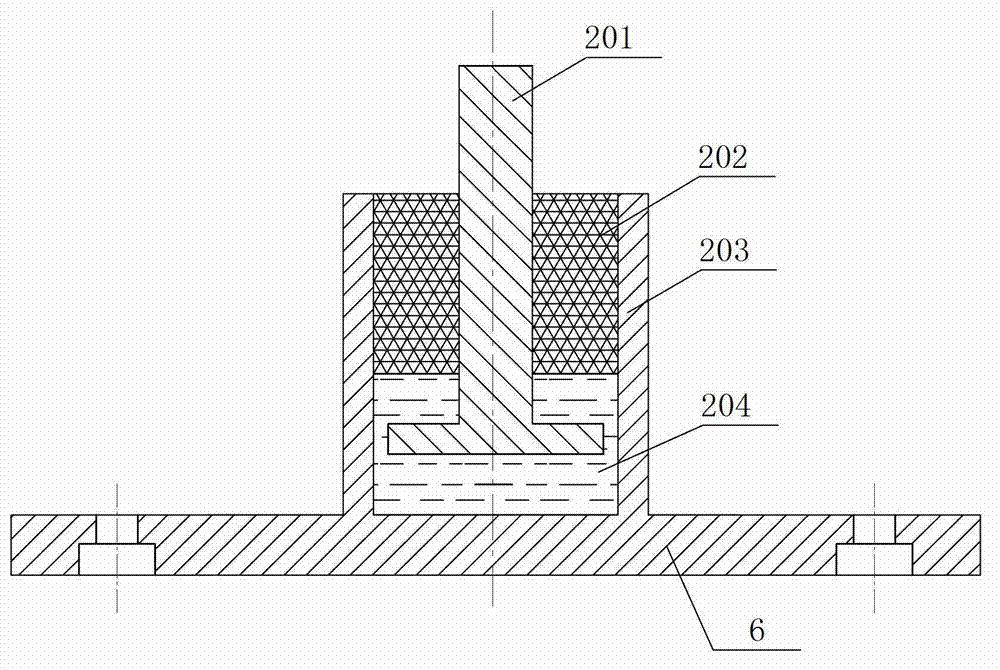

[0037] The vibration isolation mechanism includes a thick rubber support 1, a steel spring support 4 and a damping limiter 2, wherein the damping limiter 2 is located in the middle, and the damping limiter 2 is composed of a cylinder body 203, a rubber body 202, a connecting rod 2...

Embodiment 2

[0042] Embodiment 2 of a combined vibration isolation device for subways of the present invention is as follows Figure 4 As shown, the difference in Embodiment 1 is that the vibration isolation mechanism in this embodiment is only composed of a thick rubber bearing 1 and a damping limiter 2, and does not contain a steel spring bearing 4. The specific structure is: vibration isolation The mechanism includes a thick rubber bearing 1 and a damping limiter 2, wherein the damping limiter 2 is located in the middle, and the damping limiter 2 is composed of a cylinder 203, a rubber body 202, a connecting rod 201 and a viscous liquid 204, The lower end of the barrel 203 is fixedly mounted on the lower connecting plate 6, the viscous liquid 204 is installed in the barrel, the connecting rod 201 and the rubber body 202 are integrally vulcanized and molded, the rubber body 202 is plugged and pressed into the barrel and the mouth of the barrel is blocked, and the connecting rod 201 The l...

Embodiment 3

[0044] The third example of the embodiment of a combined type vibration isolation device for subway of the present invention Figure 5 As shown, the difference of the second embodiment is that the coupling rod 201 in this embodiment is a straight rod, and there is no viscous liquid 204 in the damping limiter 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com