Trailer

A vehicle chassis, left and right technology, which is applied in the field of trailers towed by motor vehicles, can solve the problems of mismatching taillight sockets and plugs, cumbersome operations, and inability to reversing, so as to improve practical safety and convenience, and improve structural reliability , Improve the effect of driving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

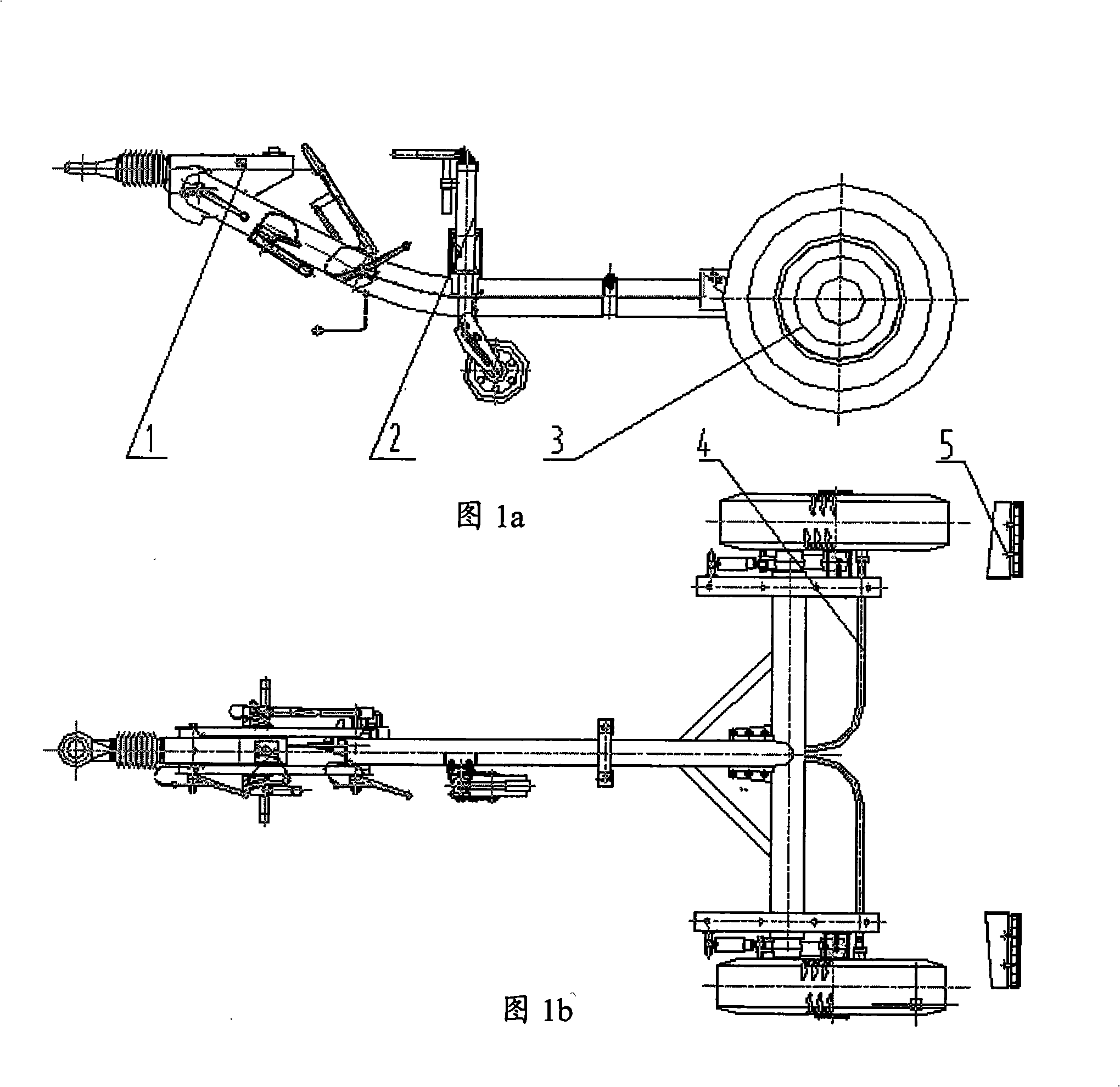

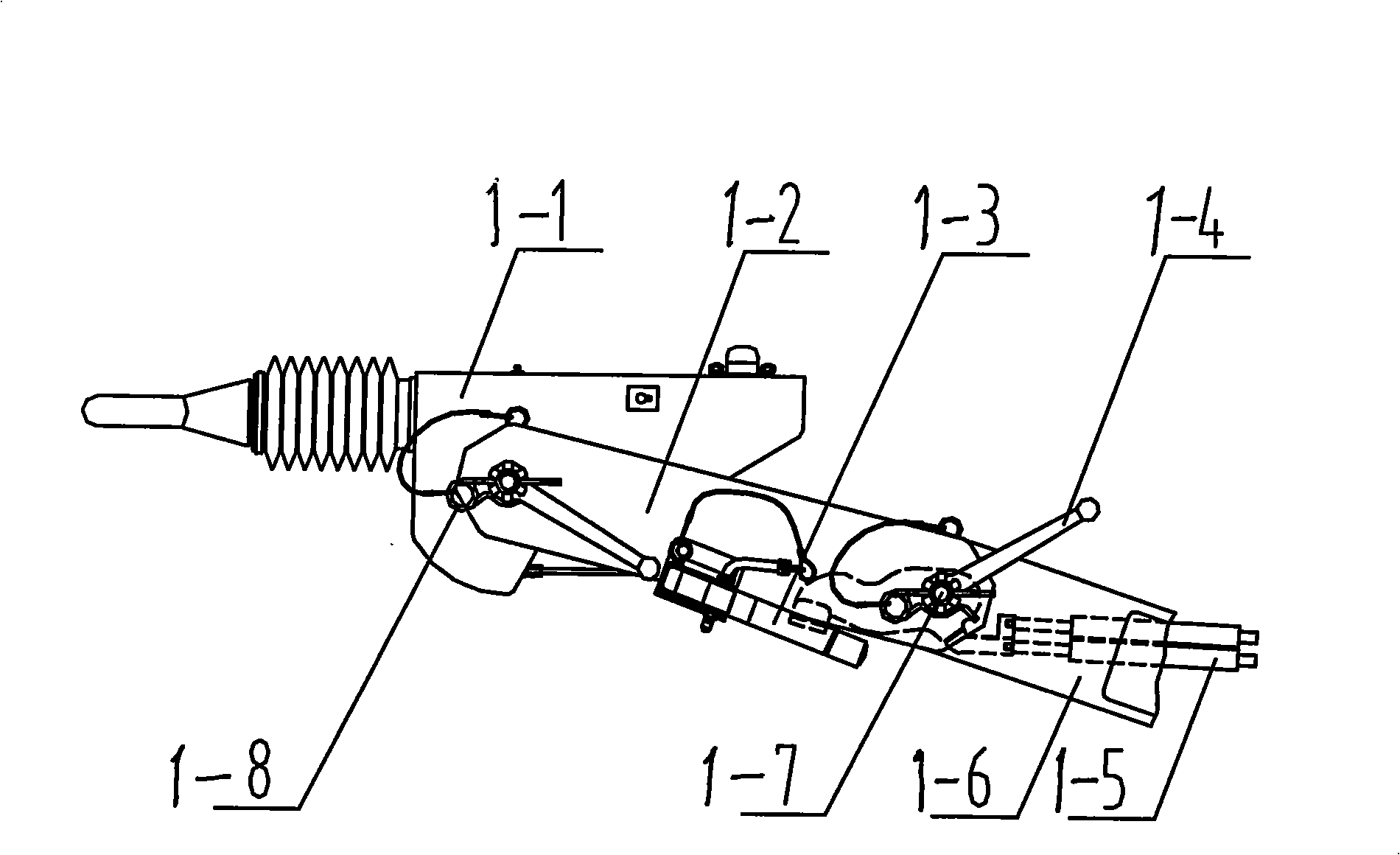

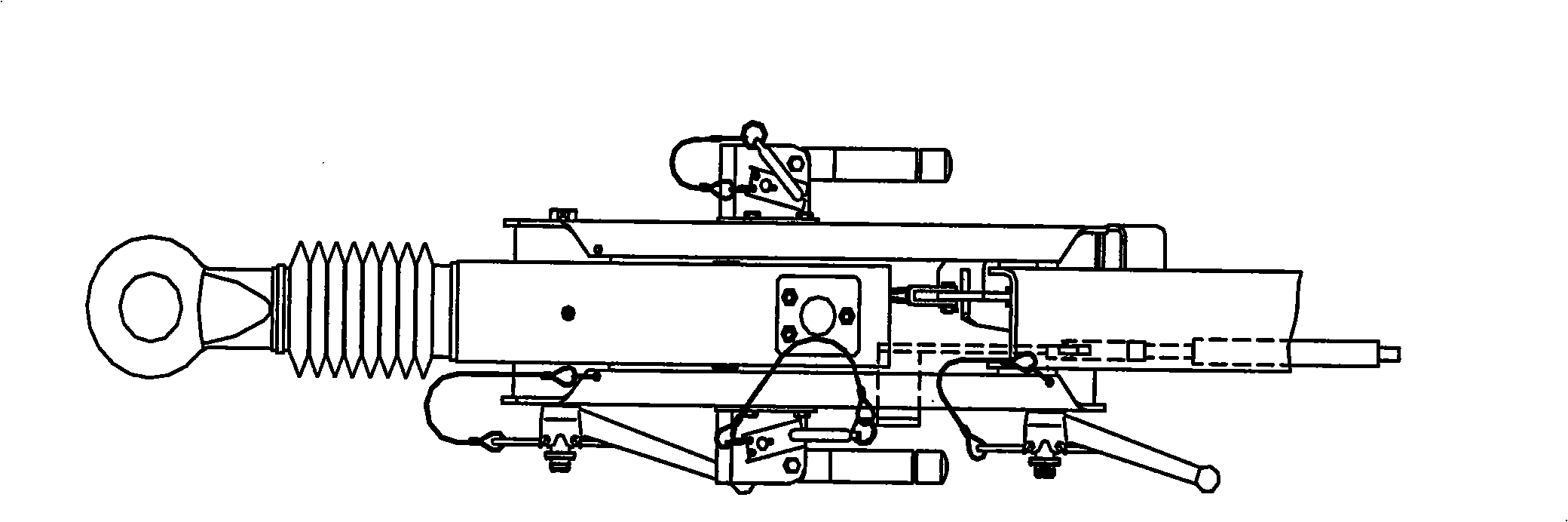

[0029] As shown in the figure, a trailer mainly includes: a trailer chassis including a traction head pinned to the front end of the symmetrical left and right pull arms, a traction beam pinned to its rear end, and left and right push rods arranged on both sides of the left and right pull arms. Traction height adjustment device 1; including the inner tube placed in the inner cavity of the outer tube assembly, the crank handle connected with the lead screw pair and the front guide support device 2 of the trailer chassis pinned to the front guide wheel bracket assembly; the trailer impact mechanism moving device 3; automatic reversing device 4 and tail light system 5, wherein:

[0030] (1) Trailer chassis traction height adjustment device, including symmetrical left and right pull arms 1-2 front-end pin-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com