Shallow buried steel column base and construction method thereof

A shallow-buried steel column technology, applied in infrastructure engineering, construction, etc., can solve the unreasonable design method of outsourced steel column feet, elongated or pulled out anchor bolts, and damage to welded parts of steel column end plates, etc. problems, to achieve the effect of convenient processing, production and construction, convenient construction, and improved seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following describes the implementation of the present invention in detail with reference to the drawings and embodiments.

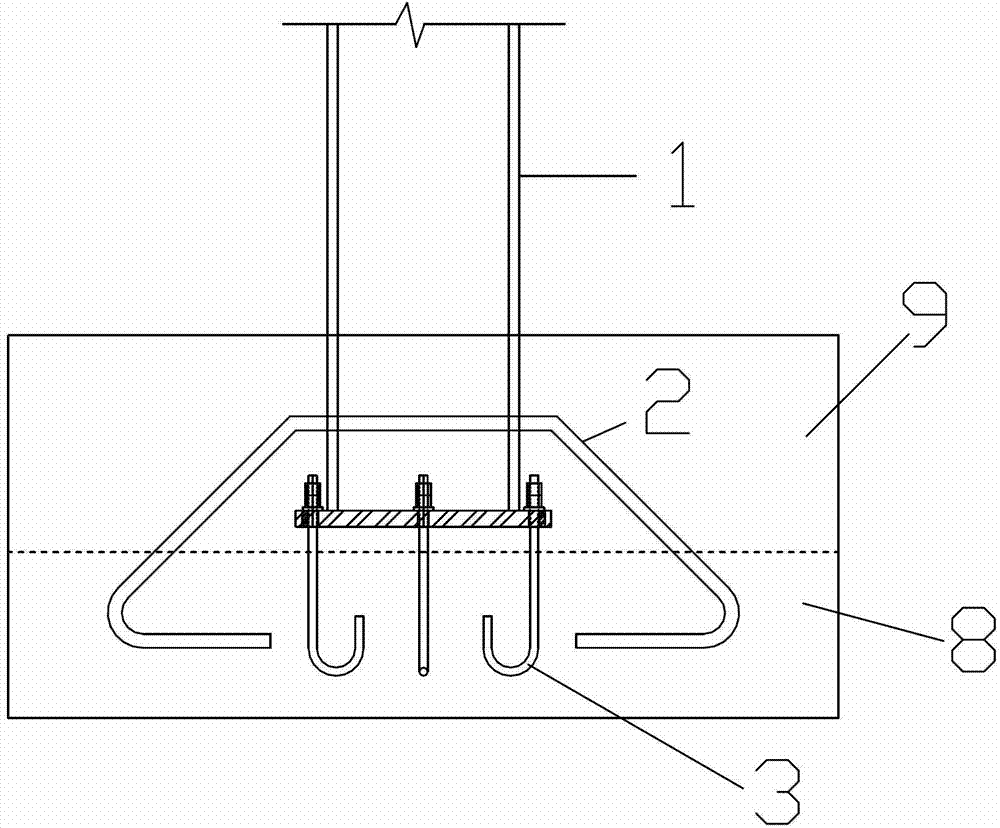

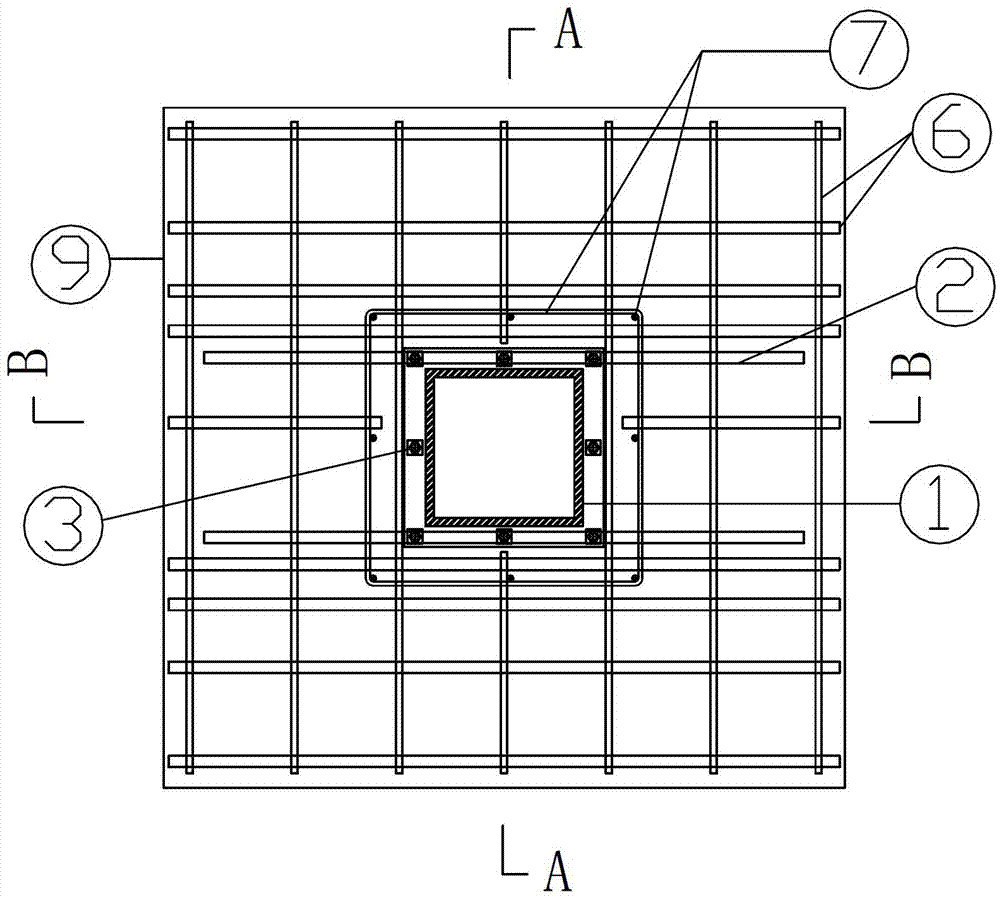

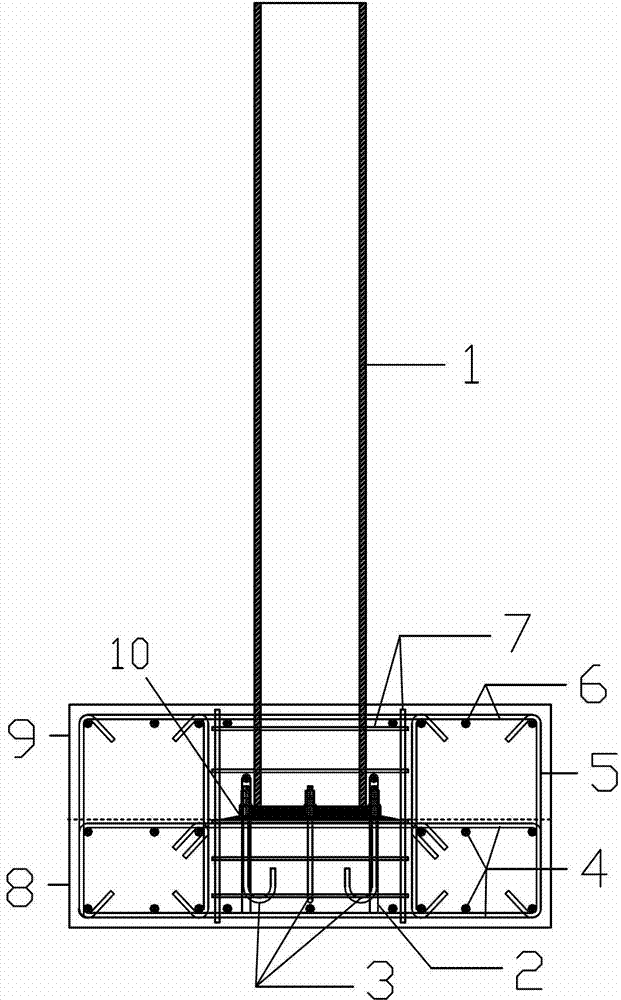

[0035] Such as figure 1 As shown, a shallow-buried steel column foot includes a steel column 1 with an end plate at the bottom, an end plate fixing anchor 3 of the steel column 1, and the other end of the anchor 3 fixed in the bottom plate or foundation beam concrete 8. The bottom of the column 1 is buried in the shallow layer of concrete 9 above the bottom plate or foundation beam concrete 8, where the steel column 1 can have an open section (such as H-shaped or cross-shaped, etc.) or a closed section (such as round, square) Or rectangular, etc.). When the closed section is selected, the concrete is poured into the bottom section of the steel column, the height of the concrete is not less than 1.5 times the thickness of the shallow buried layer outside the pipe, and the strength grade is C30~C40. The thickness of the shallow buried layer concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com