System for automatically draining water on side slope and method therefor

An automatic drainage and side slope technology, which is applied in excavation, soil protection, construction, etc., can solve the problems of inability to supplement drainage holes, high drilling cost, and difficulty in implementation, and achieves low production cost, good drainage effect, and hydrophobicity. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

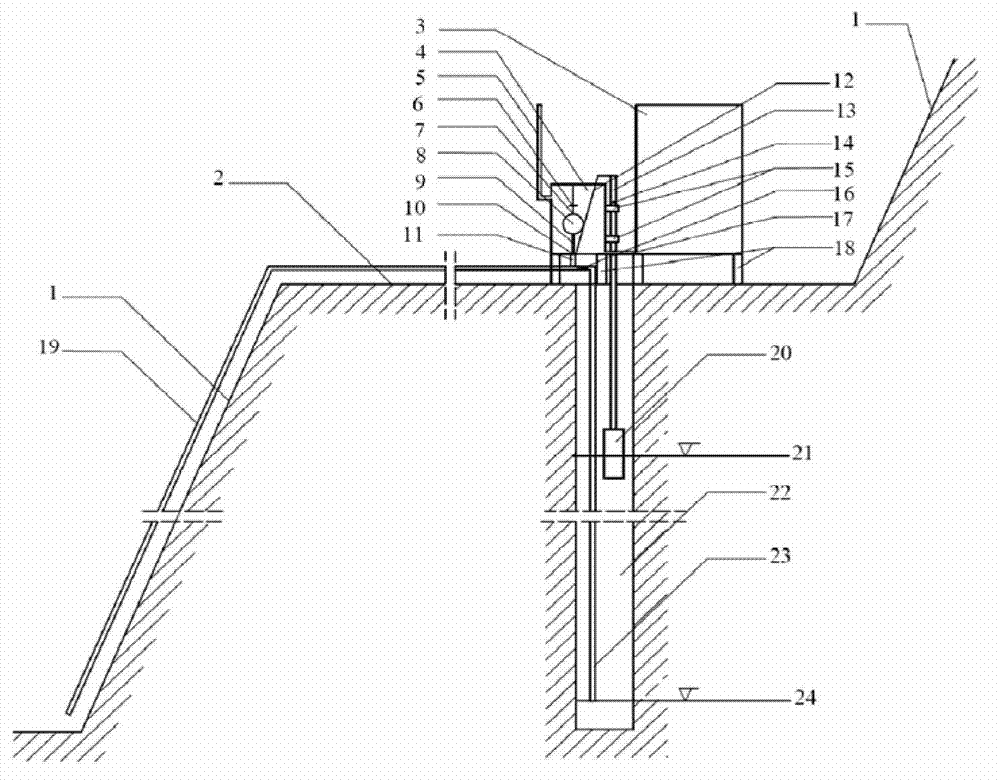

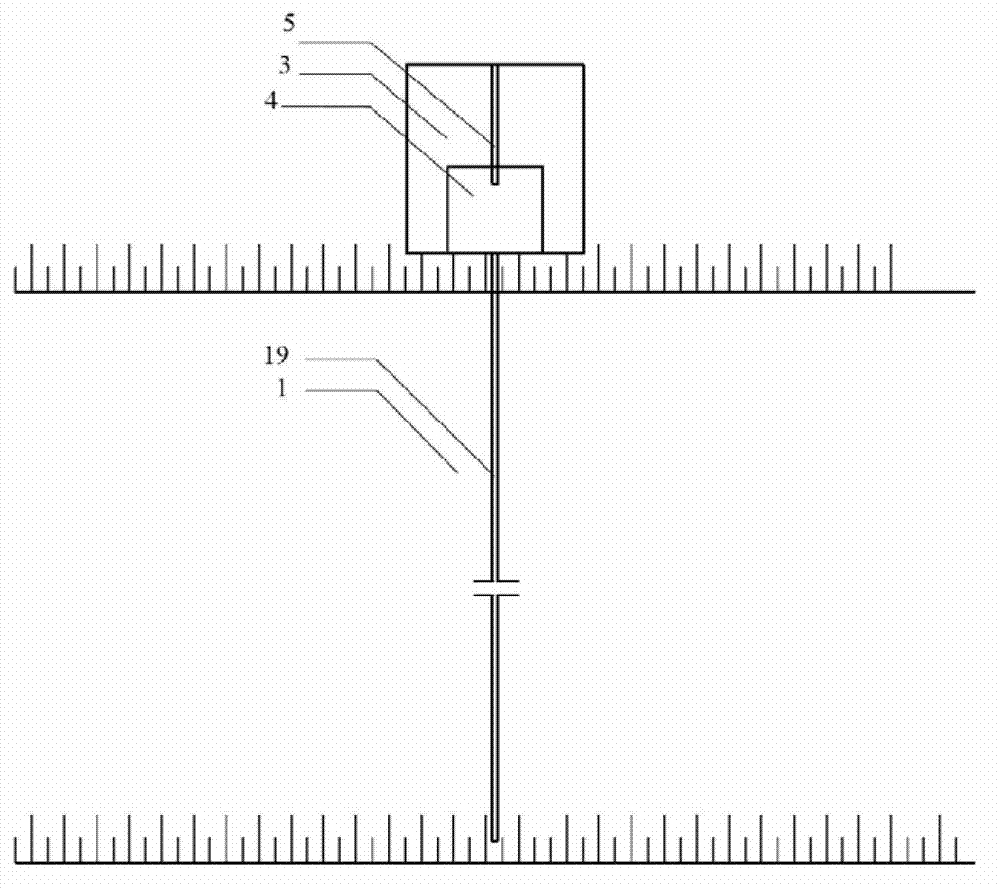

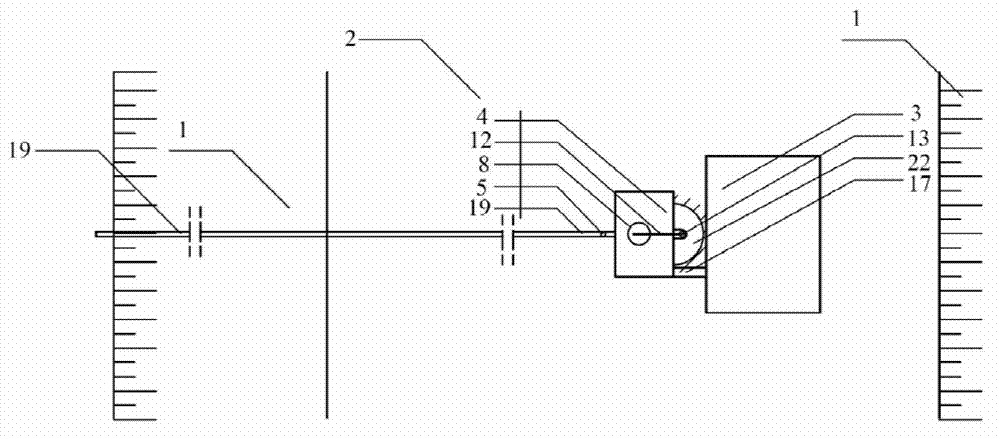

[0039] Figure 1-3 Schematic diagram of the slope drainage system. The slope automatic drainage system mainly includes three major devices: energy storage device, trigger device and drainage device.

[0040] As shown in the figure, the energy storage device includes a water storage tank 3, an energy storage tank 4, a communication pipe 17 between the energy storage tank 4 and the water storage tank 3, and a water outlet pipe 11 communicated with the drain pipe 19. In addition, in order to ensure energy storage The water flow in the tank 4 can be smoothly discharged and inflowed, and an air inlet pipe 5 which is positioned on the energy storage tank and communicated with the atmospheric pressure can also be arranged in the energy storage device.

[0041] The triggering device includes a suspension cylinder 20, a rigid buoy rod 13, a guide cylinder 15, an elastic connecting rope 12, a limit card 6, a limit nut 14, a guide rod 7, a floating ball 8, and a rigid pressure rod 9.

...

specific Embodiment 2

[0059] In order to realize the automatic drainage of multi-level slopes, a multi-stage automatic drainage system can be formed by the automatic drainage systems of the slopes in the first embodiment, and the drainage pipe 19 of the automatic drainage system of the upper step can be connected with The water storage tank 3 of the side slope automatic drainage system of the next step is connected to each other to replenish the water consumed in the latter water storage tank 3, so as to realize the step-by-step downward discharge of accumulated water on the side slope. At the same time, an overflow pipe is set at the water storage tank 3 of the automatic drainage system of the second level (sorted from top to bottom) steps and the automatic drainage system of the lower steps, to ensure that the water discharged from the upper level drain pipe 19 is filled with this After the water storage tank 3, it flows to the set final water storage location through the overflow pipe.

[0060] ...

specific Embodiment 3

[0062] Figure 4 , Figure 5 , Figure 6 , Figure 7It is a schematic diagram of the drainage action of the slope automatic drainage system. A specific example of the on-site drainage application of the slope automatic drainage system in the present invention will be described below in conjunction with the accompanying drawings.

[0063] When the water level in the catchment borehole 22 reaches the automatic drainage starting water level 21, the slope drainage system placed on a certain open-air slope step is activated, and finally the drainage system has a siphon phenomenon, and the accumulated water in the catchment borehole 22 is pumped out. To achieve the purpose of automatically draining the accumulated water on the slope.

[0064] The specific implementation process is as follows:

[0065] Step 1. System initialization. Before the automatic drainage system is started, the energy storage tank 4 is filled with water, and the floating ball 8 and the rigid pressure rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com