Corrosion inhibitor composition

A technology of composition and corrosion inhibitor, which is applied in wellbore/well parts, earthwork drilling and production, etc., can solve the problems of large amount of corrosion inhibitor, poor use effect, short action period, etc., and achieve high corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Compounding of bicyclic imidazoline and PBTCA

[0015] Weigh 2.5g of bicyclic imidazoline and 2.5g of PBTCA, mix the two agents, set the volume in a 1L volumetric flask, and set aside.

[0016] The corrosion inhibition rate at different concentrations of the corrosion inhibitor prepared in Example 1 was measured.

[0017] The test uses oilfield production fluid as the corrosion medium, the test coupon is A3 carbon steel, the test period is 7 days, and the temperature is set at 50oC. After the test, the coupons were processed to measure their corrosion inhibition rate. The results are shown in Table 1.

[0018]

[0019] As a comparison, the corrosion inhibition rate of bicyclic imidazoline or PBTCA used alone under different concentrations of wellbore corrosion inhibitors in oil wells was measured, and the results are as follows:

[0020]

[0021]

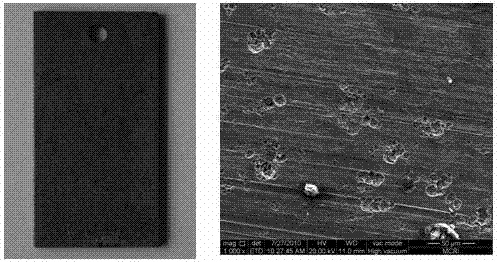

[0022] Such as Figures 1 to 3 As shown, the test results show that the corrosion inhibition perf...

Embodiment 2

[0024] Embodiment 2: Compounding of oleic acid-based imidazoline and HPMA

[0025] Weigh 2.5g oleic acid-based imidazoline and 2.5g HPMA respectively, mix and stir them, set the volume in a 1L volumetric flask, and add 50mg / L after mixing.

[0026] The corrosion inhibition rate at different concentrations of the corrosion inhibitor prepared in Example 2 was measured.

[0027] The test uses oilfield production fluid as the corrosion medium, the test coupon is A3 carbon steel, the test period is 7 days, and the temperature is set at 50oC. After the test, the coupons were processed to measure their corrosion inhibition rate. The results are shown in Table 4.

[0028]

[0029] As a comparison, the corrosion inhibition rate of oleic acid-based imidazoline or HPMA used alone under different concentrations of wellbore corrosion inhibitors in oil wells was measured, and the results are as follows:

[0030]

[0031]

[0032] The test results show that the corrosion inhibitio...

Embodiment 3

[0034] Embodiment 3: Oleic acid base imidazoline and ATMP composite

[0035] Weigh 4g of oleic imidazoline and 5g of ATMP, mix evenly, and set the volume in a 1L volumetric flask for use. Its composition is: oleic acid-based imidazoline 40mg / L, ATMP 50mg / L.

[0036] The corrosion inhibition rates of the corrosion inhibitors prepared in the above examples at different concentrations were measured. After adding 40 mg / L of oleic acid imidazoline and 50 mg / L of ATMP into the compound corrosion inhibitor of the present invention, the corrosion inhibition rate is 85%.

[0037] Change the compounding ratio of oleic acid-based imidazoline and ATMP to measure its corrosion inhibition performance. In the range of 1:5-5:1, all have a sustained-release effect of more than 80%, and the effect of 1:3-3:1 is the best. .

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com