Method for manufacturing plastic package for hazardous chemical substance

A technology of plastic packaging and manufacturing method, which is applied in the field of manufacturing plastic packaging of hazardous chemicals, can solve the problems of unusable woven bags, complicated production process, unfavorable market competition, etc., to overcome easy aging, improve stability, and overcome poor impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

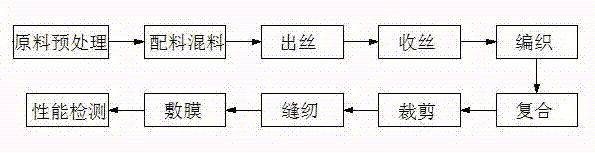

[0034] A manufacturing method for plastic packaging of hazardous chemicals, comprising the following process steps: raw material pretreatment—ingredient mixing—filing out—filing collection—weaving—compositing—cutting—sewing—coating—performance testing, wherein,

[0035]The raw material pretreatment refers to drying polypropylene, nano-plastics, waste plastic bottle flakes, whitening agent, titanium dioxide and ultramarine blue to 115°C respectively, so that each raw material contains about 2% water, and the drying time for 30min, and then crushed separately, the particle diameter after crushing is 6.5mm;

[0036] The batching and mixing refers to the batching of crushed polypropylene, nano-plastics, waste plastic bottle flakes, whitening agent, titanium dioxide and ultramarine blue with a photoelectric batching machine, accurate weighing in proportion, and then mixing the proportioned ingredients The raw materials are mixed and stirred evenly. Among them, the composition of va...

Embodiment 2

[0051] This embodiment is basically the same as the above-mentioned embodiment, the main difference is:

[0052] A manufacturing method for plastic packaging of hazardous chemicals, comprising the following process steps: raw material pretreatment—ingredient mixing—filing out—filing collection—weaving—compositing—cutting—sewing—coating—performance testing, wherein,

[0053] The raw material pretreatment refers to drying polypropylene, nano-plastics, waste plastic bottle flakes, whitening agent, titanium dioxide and ultramarine blue to 100°C respectively, so that each raw material contains about 2% water, and the drying time for 25min, and then crushed separately, the particle diameter after crushing is 4.5mm;

[0054] The batching and mixing refers to the batching of crushed polypropylene, nano-plastics, waste plastic bottle flakes, whitening agent, titanium dioxide and ultramarine blue with a photoelectric batching machine, accurate weighing in proportion, and then mixing the...

Embodiment 3

[0060] This embodiment is basically the same as the above-mentioned embodiment, the main difference is:

[0061] A manufacturing method for plastic packaging of hazardous chemicals, comprising the following process steps: raw material pretreatment—ingredient mixing—filing out—filing collection—weaving—compositing—cutting—sewing—coating—performance testing, wherein,

[0062] The raw material pretreatment refers to drying polypropylene, nano-plastics, waste plastic bottle flakes, whitening agent, titanium dioxide and ultramarine blue to 110°C, so that each raw material contains about 2% water, and the drying time for 28min, and then crushed separately, the particle diameter after crushing is 5.5mm;

[0063] The batching and mixing refers to the batching of crushed polypropylene, nano-plastics, waste plastic bottle flakes, whitening agent, titanium dioxide and ultramarine blue with a photoelectric batching machine, accurate weighing in proportion, and then mixing the proportioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com