Preheating method before welding of thick-wall aluminum alloy

A technology of aluminum alloy and aluminum alloy tube, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large flame preheating temperature range, low production efficiency, long preheating time, etc. Product quality, improving production efficiency, and the effect of uniform heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0013] The preheating method before thick-walled aluminum alloy welding of the present invention, its preferred embodiment is:

[0014] Weld small-sized plates on large-sized aluminum alloy pipes, conduct induction heating from the inside of the aluminum alloy pipes before welding, and heat the plates through heat conduction, so that the aluminum alloy pipes and plates Achieve consistent temperature and balanced preheating in a short time.

[0015] An induction coil consistent with the length of the aluminum alloy pipe is used to extend into the interior of the aluminum alloy pipe for heating.

[0016] The whole of the aluminum alloy pipe is heated.

[0017] The equipment used for heating is an induction heating equipment.

[0018] The method for preheating the thick-walled aluminum alloy before welding can improve product quality, increase production efficiency, and ensure the safety of welding structures.

specific Embodiment

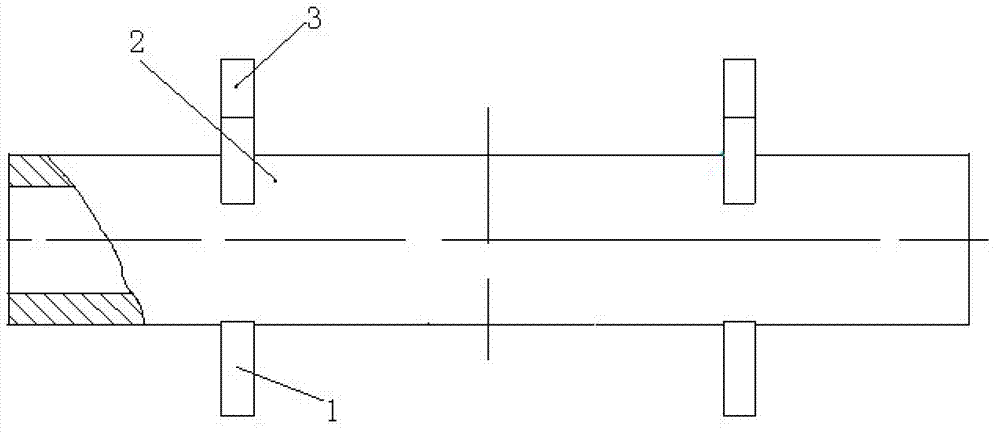

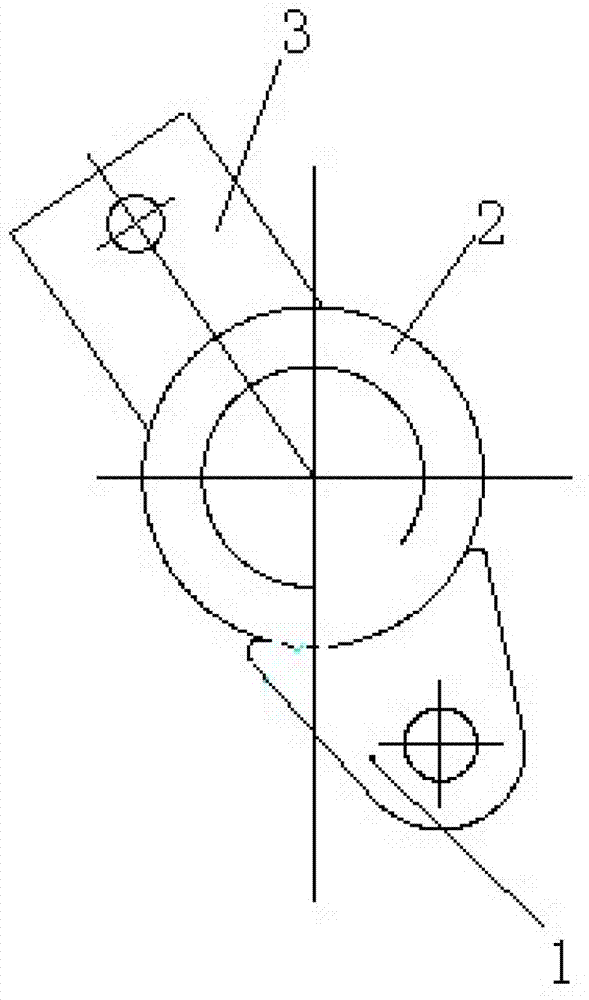

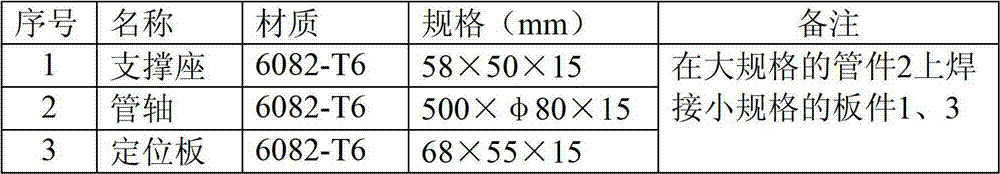

[0019] Such as figure 1 , figure 2 As shown, the support seat 1 and the support seat 3 need to be welded on the tube shaft 2, see the table and figure below:

[0020]

[0021] Induction heating equipment is used for preheating before welding;

[0022] The outer diameter of the produced induction coil is 48mm and the length is 500mm;

[0023] Insert the induction coil into the inner diameter of the pipe shaft, that is, mainly heat the pipe as a whole from the inner wall of the pipe: the two ends of the induction coil are flush with the two ends of the pipe shaft, so that the preheating area becomes larger, and the temperature of the support seat and the positioning plate is guaranteed to be consistent with the heat transfer. The temperature of the tube axis is basically the same, avoiding welding defects such as incomplete penetration and thermal cracks caused by the heat imbalance of parts of the two sizes, and reducing the large tensile stress caused by thermal stress i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com