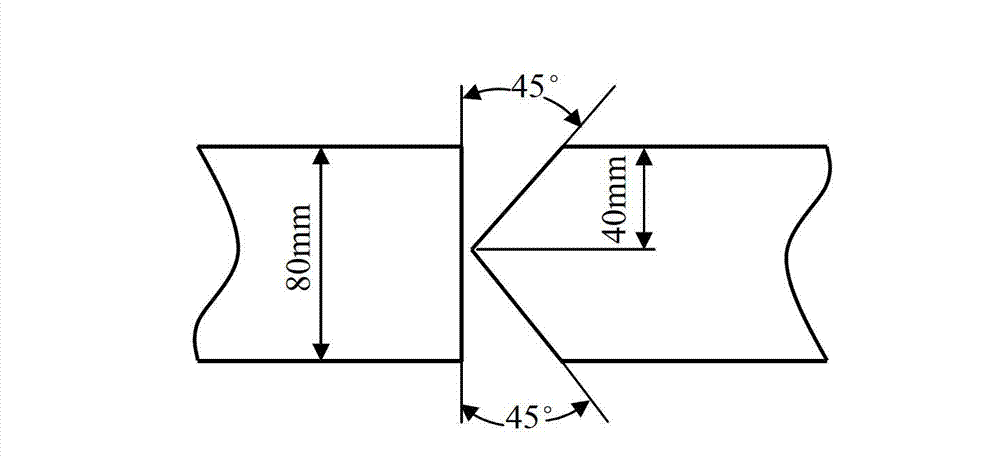

Flux-cored arc welding method for K-shaped groove of 80-mm super-thick steel plate

A technology of gas-shielded welding and gas-shielded welding wire, which is applied to welding equipment, arc welding equipment, and the edge of workpieces, etc. It can solve the problems of large residual stress in the weld seam, high rigidity of the extra-thick steel plate structure, and fast cooling speed. The effect of performance satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

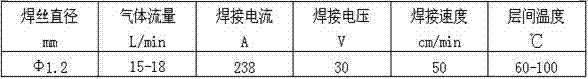

[0020] This embodiment is a gas-shielded welding method for 80mm extra-thick steel plate K-groove flux-cored wire. Two pieces of E36N-Z35 marine engineering with a size of 800mm (steel plate longitudinal)×200mm (steel transverse direction)×80mm (thickness) are selected. The steel plates are spliced with flux-cored wire gas shielded welding, the shielding gas is 100% carbon dioxide gas, and the two steel plates are spliced and welded with a line energy of 6kJ / cm. Before welding, the test plate is machined with a symmetrical K-shaped groove, and then press figure 1 Assembled by the method in the above, the base welding is performed first. Then perform gas shielded welding with flux-cored wire on the front side, weld to 2 / 3 of the depth of the groove, and then clean the root with carbon arc gouging or a grinder machine. After polishing, perform gas shielded welding with flux-cored wire on the back side. Solder the rest of the front side after the soldering is complete. The ...

Embodiment 2

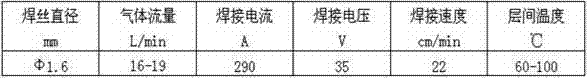

[0025] This embodiment is a gas-shielded welding method for 80mm extra-thick steel plate K-groove flux-cored wire. Two pieces of E36N-Z35 marine engineering with a size of 800mm (steel plate longitudinal)×200mm (steel transverse direction)×80mm (thickness) are selected. The steel plates are spliced by flux-cored wire gas shielded welding, and the steel plates are spliced and welded with a line energy of 20kJ / cm. Before welding, the test plate is machined with a symmetrical K-shaped groove, and then press figure 1 Assembled by the method in the above, the base welding is performed first. Then carry out gas-shielded welding with flux-cored wire on the front side groove. The shielding gas is 100% carbon dioxide gas. After welding to 2 / 3 of the groove depth, carbon arc gouging or root cleaning with a grinder is performed, and then the reverse side groove core is performed after polishing. Welding with wire gas shielded welding, after all the reverse side is welded, weld the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com