Semi-automatic welding equipment for automobile water falling groove

A semi-automatic welding and sinking technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of multiple beating, wrong welding of welding points, and inability to detect and control the welding depth, so as to avoid misoperation and difficulty in operation. Bottom, avoid the effect of wrong solder joint position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

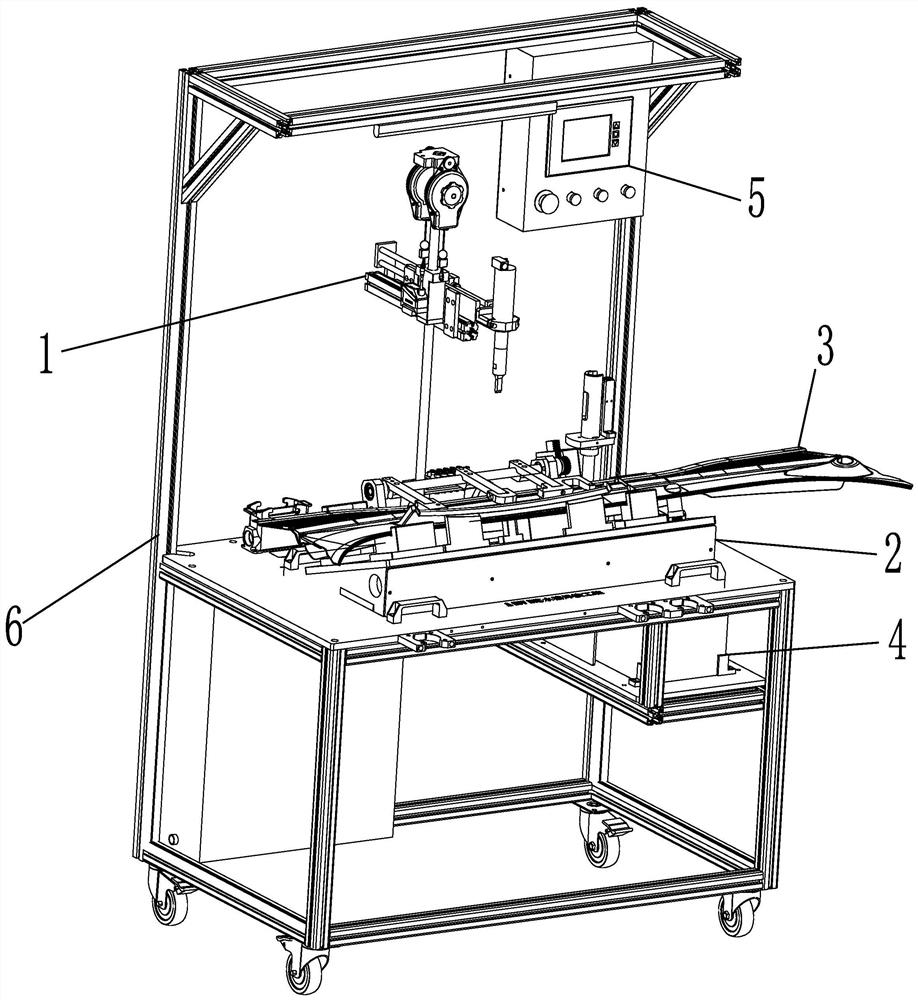

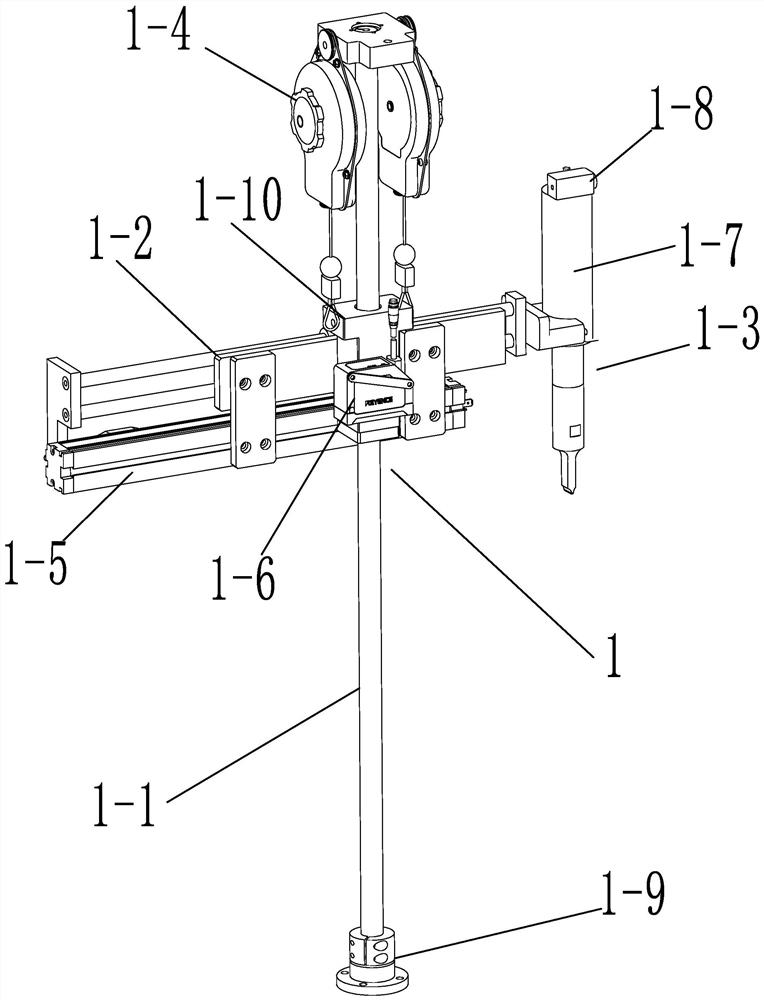

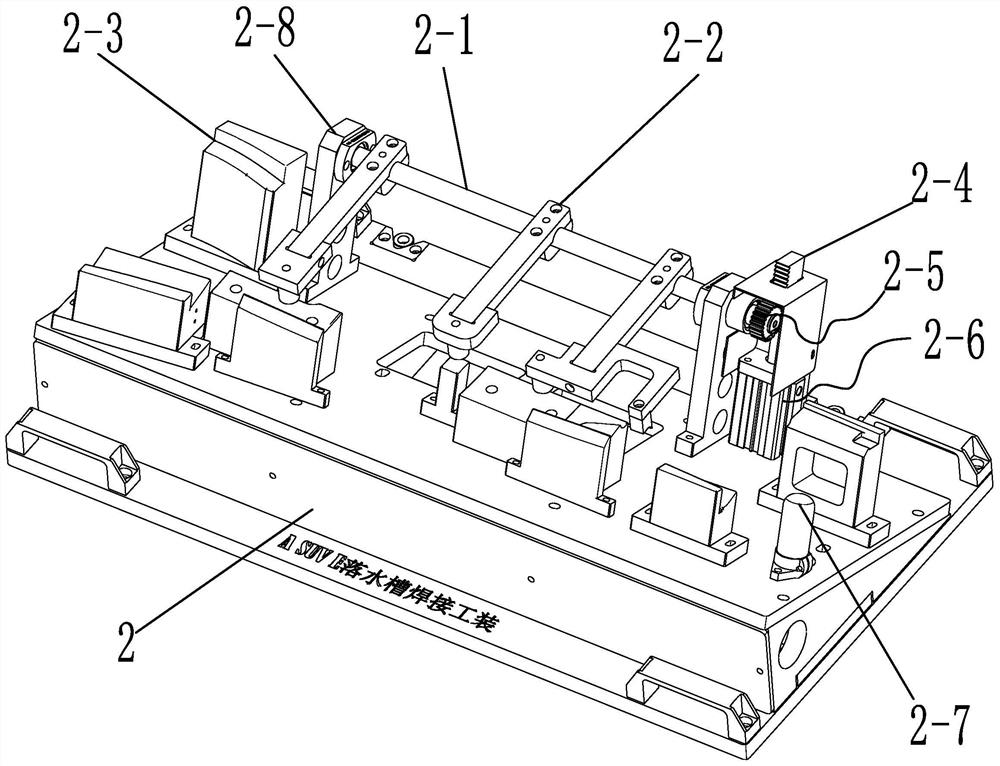

[0020] exist Figure 1 to Figure 4 In the shown embodiment 1, a kind of semi-automatic welding equipment for automobile gutters of the present invention includes a workbench 6, a welding device 1, a welding fixture 2 and a controller. The workbench is a profile frame with a 6-shaped cross section, It includes a rectangular table top, four rollers at the bottom of the workbench and a light tube at the top of the workbench. The rollers facilitate the movement of the workbench. The light tube is used to increase the illumination and make it easier to find the welding point 3-1. The welding device comprises a cylindrical vertical rod 1-1, a cuboid slide block 1-10, a telescopic arm 1-2 and a welding torch. The vertical rod is fixedly arranged on the inner side of the workbench, and the vertical rod is perpendicular to the table top. The slider is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com